By William Perkins

Like having a whole other gun

Many M16 owners are aware of the advantages of a .22LR conversion. Rimfire ammunition is 90% cheaper than US made .223 ammo. The modest recoil and noise is less intimidating when introducing shooters to NFA firearms and occasionally, a friendly match director will allow you to enter pistol matches that would be ineligible with the 5.56 mm round.

J.A. Cieners’ conversion for the M16 possesses several key advantages over the alternative .22 LR conversions. The availability of ‘high capacity’ magazines, replacement parts, and the ability to shoot full auto are exclusive to the Ciener “Atchisson” kit. Rather than use the conversion in an existing upper receiver, a decision was made to dedicate a complete upper assembly to the .22 Long Rifle. This approach has several advantages. Since there is no gas port or gas block needed in the direct blowback conversion, the barrel can be any length greater than the 4” required for reliability. The dedicated receiver will have its own sights which do not have to be re-zeroed when converting from 5.56 mm to .22LR for precision shooting at aluminum cans, and concerns about lead build-up in the chamber becomes a non-issue.

Selecting components

Several upper receivers are particularly well suited for a dedicated .22 LR upper. Since the forward assist is not functional with the Ciener kit, it is preferable to have a receiver that does not have the F/A mechanism. Potentially the anti-bounce weight can catch on the edge of the hole of the F/A during the dynamics of cycling unless it is properly beveled. The Les Baer flattop without forward-assist was selected. The DPMS Lo-Pro and American Spirit 9mm upper receiver would also be appropriate, but the Lo-Pro does require modification at the rear takedown lug to clear the full-auto sear. Due to the SD configuration, a front sight would be problematic. Selecting an A3 style receiver and adding optics avoided the issue.

For economy, a used de-milled 5.56 mm barrel was selected. Starting out with a used barrel with the wrong twist (1 in 7” to 1 in 12” typically) with the wrong groove diameter (.223”) is less than ideal. Accuracy is not spectacular as one would expect, but it will deliver 6” groups or better at 100 yards with most ammunition. This is acceptable for its intended purpose and use with a dot scope. With the popularity of High-power shooting and IPSC 3-gun matches, finding a used but suitable barrel is not difficult.

If accuracy is a higher priority, this is easily achieved with a scoped receiver using a dedicated custom barrel from Accuracy Speaks, Kurt’s Custom Firearms or Kuehl Precision. This eliminates the chamber adaptor and allows the barrel to be cut 2” shorter with the same length of rifling. A substantial improvement in accuracy will result from having a barrel with the proper groove diameter (.221”) and the optimal 1 in 16” twist rifling.

GG&G manufactures the mount for the Aimpoint Comp M2 electronic scope. The handguards selected are ‘mid-length’ versions from Rock River Arms to keep the proper proportions. A Stow-A-Way pistol grip holds the tax stamps.

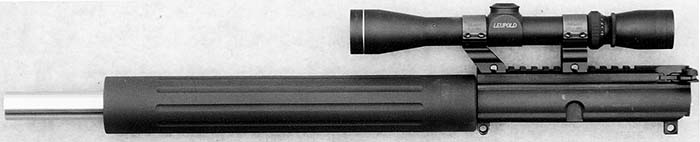

The ‘Hornet’ suppressor by Gem-Tech is particularly suited to this application. It was designed for full-auto rimfire or the .22 Hornet cartridge. It is lighter and more compact that most .223 suppressors and considerably more robust than suppressors intended for semi-auto rimfire firearms. Its 1 1/4” diameter allows the use of a modified handguard cap and handguards to keep the military ‘look’ of the firearm. A common alternative when using a larger diameter suppressor is to use a free-floating handguard partially overlapping a dual-purpose .223/.22 LR suppressor. Shown in the photo below is an AWC ‘Optima’ on an M16 A1 barrel that has been cut and threaded at 5 1/2” (3” of rifling).

Assembling the parts is easy and only requires one specialized tool. Apply molybdenum disulfide grease to the threads of the upper receiver and torque the barrel nut, loosen and repeat several times. This makes for a better thread fit and more durable assembly. Proper assembly requires a minimum of 31 ft. lbs. not to exceed 80 ft. lbs. to align the barrel nut on the upper receiver.

For an even quieter performance, add a recoil buffer. This works to attenuate the action noise by eliminating the metal-to-metal slap when the bolt recoils to the rear after a shot is fired. Conveniently, the diameter of the recoil spring and guide rod in Ceiner’s M16/22 kit is the same as the one used in his 1911 conversion. Adding the buffer from the 1911 kit was simply a matter of trimming a little excess material. Results are not dramatic, but are worthwhile.

Disenchantment

Every firearm seems to have its own personality and rimfire guns are no exception. Seemingly identical guns can have different preferences for accuracy and reliability. Only by shooting a variety of ammunition can one determine what the favorites are. On the first trip to the range with my new conversion, there were five-to-twenty malfunctions per 30-round magazine regardless of ammunition selection. Clearly, there were underlying mechanical problems that had to be sorted out before proceeding further. The symptoms demonstrated that there were at least four different problems.

Several different types of malfunctions can occur in the Ciener conversions. Diagnosis is always the most difficult job; different problems can have the same symptoms and some problems cause different types of malfunctions. One type is a failure to eject, known as the ‘stovepipe.’ It is easy to recognize, but can have several causes.

Another failure to eject is the ‘bolt face’ malfunction. This is more difficult to clear because the empty brass becomes trapped between the face of the bolt and the charging handle. Pulling on the charging handle smashes the case further. To clear the action the bolt must be retracted without using the charging handle. Strong fingers can use the indent in the bolt exposed thru the ejection port and force it to the rear. Occasionally, disassembly is necessary.

Failures to feed can be mistakenly blamed on feed ramp angles when the problem is excessive friction in the action. A ‘hammer down’ malfunction can be difficult to diagnose since the problem cannot be seen when the gun does not fire. When the hammer has followed the bolt forward, added resistance will be felt when the charging handle is pulled to the rear because of the additional force required to re-cock the hammer. Frequently a live round will be ejected.

A phone call to J. A. Ceiner was helpful. Since the kit was new, Larry offered to fix the problems for free. “That’s what we do. We play with guns all day.” Wanting to gain a better understanding of how it works, the offer was declined. Larry took the time to explain the source of several problems, the typical pitfalls, and what clues to look for. Alternatively, Ceiner will tune-up conversions that are out of warranty for $40 per-hour plus parts. One hour is typical in most circumstances.

Diagnosing the problem

Start by unloading the gun and putting away all ammunition. Thoroughly clean the gun, the conversion and the magazines with solvent and a toothbrush. Suppressed firearms are inherently dirtier, depositing more residue into the action due to the increased backpressure. This, combined with the smaller parts necessary in a caliber conversion, and the dirtier rimfire ammunition will lead to higher maintenance requirements.

Permanently number the magazines with pressure sensitive stickers or a scribe. Magic marker will wipe off when exposed to gun cleaning solvents. It is a good idea to re-blue all shiny spots on the magazines. Cold blue works fine. It is important to be able to see very small wear points. These clues will lead to the correct diagnosis and solution.

Carefully disassemble the conversion and inspect the parts. The bolt rails should be checked with a straight edge to ensure that they are not bent. Use a file to ad a slight bevel on the forward end of the rails. This will make it easier to insert the conversion into the upper receiver. The bolt face should be brushed clean. Inspect the extractor. It should have a sharp, knife-like edge to engage the rim of the case and good spring tension.

The conversion does not hold the bolt back after the last round is fired. When shooting the gun full-auto it is ‘dry-fired’ after the last round is ejected from the gun. Check the chamber adaptor for damage that this can cause. It should not have any burrs from the firing pin. These can cause feed and extraction problems.

Make sure that the feed ramp is free of machine marks. Lead shavings indicate some work is required. Do not use files or stones on the feed ramp. There is not enough metal there to correct a mistake. Lightly use either a 1/4’ Cratex™ wheel or Flitz™ metal polish on a felt drum on a Dremel? tool set on low speed. Do not try to remove all the machine marks. A mirror like finish is not necessary. When using the Dremel™ tool, be careful that the chamber is not opened up or case-head blowouts may occur.

Failures to feed can be caused by cutting the recoil spring shorter, in an attempt to make low powered ammunition eject reliably. Failures to feed when loading the gun are frequently misdiagnosed. The added resistance of the charging handle latch can cause a problem. Cutting 6 coils off the latch spring will make it easier for the bolt and charging handle to return to battery when chambering a round.4 Improper loading technique will also appear to be a failure to feed. After the charging handle is pulled to the rear it should be allowed to slip from the fingers so the bolt will return to battery at full spring pressure. Riding the charging handle forward robs the energy needed to strip a round from the magazine and push it into the chamber.

If your upper receiver has forward assist, inspect the anti-bounce weight where it passes the F/A mechanism. Wear marks will indicate if it is catching on the edge of the hole. This can be another source of unexplained malfunctions. If necessary, bevel the leading and trailing edge of the anti-bounce weight a few thousandths of an inch at a shallow angle and re-blue.

Next, polish the bottom of the bolt in the center. A disposable fingernail emery board is ideal.

When a round is fired, the bolt extracts the spent case and recoil forces it back out of battery. During this time, the spring in the magazine is forcing the ammunition up against the bottom of the bolt. Too much friction will prevent the bolt from traveling back far enough for the hammer to catch the sear, even though it may eject the empty and reload the chamber. If the bolt recoils less than 1.35” the hammer rides the bolt forward when it returns to battery. Reducing this friction helps eliminate the ‘hammer down’ or ‘dead trigger’ malfunctions. This usually occurs when the magazine is almost full and the spring pressure is greatest. Improper sear timing can also cause the ‘hammer down’ malfunction. This occurs most frequently with ‘drop in auto-sears’ in converted semi-auto guns due to different take down lug dimensions. If the hammer is released early, it will ride the bolt forward and not hit the firing pin hard enough to fire the round. In this situation it is possible to delay the trip of the auto sear by removing metal from the inside of the Ciener auto-sear trip. This will allow the bolt to return further into battery before releasing the hammer. However, if it is delayed too much, the gun will not fire full-auto.

Ammunition selection

Like any other firearm, proper ammunition selection is essential for good performance. Remington ‘High Velocity’ part # 1522 is the recommended ammo; Winchester ‘Super-X’ is comparable.5 Larry emphasized the importance of 40g bullets. Lighter bullets may lack the recoil impulse necessary to cycle the action reliably. Most economically priced .22 LR bulk boxes use a 36g bullet.

Another issue is the preference to shoot copper plated bullets in order to minimize lead build-up inside the suppressor. Lead bullets accelerating down the barrel develop enough friction against the lands to vaporize a small percentage of the bullet. This vapor condenses inside the suppressor. Using copper plated ammunition mitigates this problem to some degree, and is preferable to un-plated lead bullets. Also, copper-plated bullets do not have the waxy bullet lube that is used on lead bullets. This keeps the action cleaner and more reliable. Since this firearm is suppressed, the most enjoyable shooting is done with subsonic ammunition. Avoiding the sonic crack makes any suppressed gun dramatically quieter. The catch is that some ammunition labeled as subsonic does not have the energy required to cycle the action. A short barrel does help keep the ammunition subsonic, but it is still a fine line. As a general rule, most ammo labeled as ‘match,’ ‘target’ or ‘standard velocity’ will be sub-sonic out of pistol length barrels. From this barrel, I have chronographed; CCI Mini-Mags at 1193 fps, Federal Classic #710 at 1099 fps, Winchester Super-X ‘High Velocity’ at 1086 fps and Remington ‘High Velocity’ at 1075 fps. Although the last three mentioned are only subsonic in warmer temperatures, slower ammunition does not offer the recoil impulse necessary for good reliability with this particular combination. For best suppressor performance and accuracy, the velocity should be no more than 1000 fps.

Finding ammunition that is clean, accurate and reliable but sub-sonic may vary from gun to gun, but discovering it is all part of the fun. Warning: if you ever have a case rupture, stop shooting immediately. There could be a bullet stuck in the chamber. Firing another round could ruin the barrel.

A tune-up for the magazines

When a malfunction occurs, write down the type of malfunction and which magazine was used. The majority of malfunctions are magazine related. After shooting the gun with each magazine several times, there will be enough information to get started on the next step.

The magazines should fit snugly in the lower receiver. If they drop free when the magazine release is pushed in, they may be too loose. A sloppy fit allows the magazine to move about while the gun is cycling causing intermittent problems. A stable magazine is necessary for reliable functioning. Gently pry the magazine adaptor apart at the top and bottom, front and back, until the fit is just snug. Next, measure the distance between the feed lips with a dial caliper. This dimension is critical for proper feeding since it determines the timing, when the magazine releases the cartridge to be fed into the chamber. It should measure .210” at the back and .240” wide at the front of the feed lips with a slight hourglass curve. Gently make adjustments so that they are symmetrical and of proper dimensions.

Look at the left feed lip for a shiny spot. It may be easier to see when the magazine is in the gun. Just in front of the ejector the extracted brass has been rubbing on the feed lip. This is the cause of the ‘bolt face’ and ‘stovepipe’ malfunctions. When a fired case is extracted from the chamber, the left feed lip acts as the ejector and flips the empty brass up instead of allowing the ejector to kick the brass out the ejection port. The bolt is then pushed back into battery by the recoil spring trapping the empty between the bolt face and the charging handle. This feed lip is either too tall or bent too far in. If necessary, stone down this feed lip .003” and re-blue.

It may be tempting to file the magazine notch higher in the magazine body so that it sits lower in the gun, but this is not advised. Raising the notch does not prevent the magazine from being inadvertently pushed in further, which would duplicate the malfunction. High power shooters using the offhand position exacerbate the problem by using the heel of their hand under the magazine to hold up the gun. Shooting off the bench with sandbags under the magazine has the same effect.

If the top of the right feed lip is shiny, the bottom of the bolt is rubbing on the feed lip as it cycles. This increased drag can cause failures to feed, failures to extract and ‘hammer down’ malfunctions. Use a medium stone to remove several thousandths of an inch of metal from the right feed lip where it makes contact. Re-blue and reinsert into the gun. A trip to the range is not necessary. Simply cycle the action repeatedly with an empty gun and re-inspect the magazine. If necessary, continue stoning. Maintain the correct angle of the feed lips and be aware that changing the height can affect the feed lip separation. Proceed slowly and measure frequently.

Cleaning the inside of the magazines on the conversion is required more frequently than a 5.56 mm application for several reasons. Rimfire ammunition is notoriously dirtier than centerfire ammunition and short suppressed barrels amplify this substantially. Also, the magazine and action springs used in the .22 LR conversions are considerably weaker than the springs used for the .223 cartridge. This makes the mechanism more susceptible to powder fouling and other foreign material. Disassemble the magazines and using a hemostat or a tongue depressor, rub a scotch-brite pad inside the length of the body while being cautious of the feed lips. Recently, I’ve been using a Bore Snake inside the magazines. “The World’s Fastest Bore Cleaner”™ in .40 cal is just right and more convenient in the field. Unburned powder, bullet lube, and lead deposits all work against proper functioning. Do not lubricate the insides of the magazine. Lubricant only attracts and holds those deposits.

Resolution

After talking to the right people and taking the time to properly analyze the problems, several hours were spent working on the conversion. The result was rewarding. The next time out, the gun was passed around among a number of shooters. With several people loading magazines for each other, the ammunition quickly disappeared. Towards the end of shooting, the gun had 3 malfunctions, one stovepipe and two failures to feed. A thorough cleaning revealed that the left bolt rail had a hard, baked-on build-up of burnt powder residue. This added a noticeable amount of friction to the action. Evidently, around the 300 round mark, a thorough cleaning is necessary. Since then, an additional 3000 rounds have been fired. Cleaning the gun every 300 rounds allows the gun to remain dependable and is a necessary precaution to prevent malfunctions. I don’t consider it to be 100% reliable, but then again, my life does not depend on it. That is not its purpose; it is entirely for fun, and in that roll, it meets all expectations. Rimfire conversions are entertaining when they work and frustrating when they don’t. Their perceived mechanical simplicity belies the complicated engineering that went into them. With a little diagnosis and tuning, the Ceiner .22 conversion is a rewarding accessory for the M-16.

After well over 10 years of production, the popularity of the Ciener M-16 conversion is as strong as ever. With a supply of over 10,000 ‘grandfathered’ high capacity magazines still available10, its future is assured. There are a staggering number of ways to build a dedicated upper. From economical plinkers using leftover or surplus parts for the recreational shooter, to match grade barrels with high-powered optics for the serious competitor. Building one is not technically demanding, and you just might have a few parts lying around that fit the bill.

Sources:

Accuracy Speaks

Match barrels and complete uppers

www.accuracyspeaks.com

Dept. SAR

3960 N. Usery Pass Rd.

Mesa, AZ 85207

(480) 373-9499

Les Baer Custom Inc.

Parts and complete guns

www.LesBaer.com

Dept. SAR

29601 34th Ave.

Hillsdale, IL 61257

(309) 658-2716

Jonathan Arthur Ciener

.22 Conversion kits

www.22lrConversions.com

Dept. SAR

8700 Commerce Street

Cape Canaveral, FL 32920

(321) 868-2200

DPMS

Parts and complete guns

www.DPMSinc.com

Dept. SAR

13983 Industry Avenue

Becker, MN 55308

(800) 578-DPMS

Scott Fischer, aka Mongo

Web page dedicated to the M16-22LR

www.flash.net/~scfische/m1622/M1622.htm

Gem-Tech

Suppressors

www.Gem-Tech.com

Dept. SAR

P.O. Box 140618

Boise, ID 83714

(208) 939-7222

GG&G

Accessories

www.GGGaz.com

Dept. SAR

3602 E. Stravenue

Tucson, Arizona 85713

(520) 748-7167

David Hineline

Used M-16 barrel

DCH-Manuf@mindspring.com

Dept. SAR

724 E. 15th Street

South Sioux City, NE 68776

Kuehl Precision Firearms

Barrels and complete .22 uppers

www.KuehlPrecisionFirearms.com

Dept. SAR

P.O. Box 260

Labadie, MO 63055

(314) 330-2666

Kurts Custom Firearms

Barrels and complete .22 uppers

www.Kurts-Kustom-Firearms.CitySlide.com

Dept. SAR

6167 S.E. 26th St. Suite A

Bushnell, FL 33513

(352) 793-2346

Rock River Arms

Mid-Length handguards

Dept. SAR

www.RockRiverArms.com

101101 Noble Street

Cleveland, IL 61241

| This article first appeared in Small Arms Review V5N11 (August 2002) |