By Frank Iannamico

Most Small Arms Review readers are familiar with the MAC family of submachine guns, designed by the late Gordon Ingram, and originally mass produced by the Military Armament Corporation during the 1970s. The Model 10, aka the MAC 10, was manufactured in 9mm and .45 ACP. The Model 11, aka the MAC 11, was a smaller .380 caliber weapon. Several years after the demise of Military Armament, Wayne Daniel introduced the 9mm M11/Nine submachine gun. The M11/Nine was offered in both submachine gun and semiautomatic models. The diminutive guns were sold through Mr. Daniel’s company SWD, and proved to be very popular.

The MACs and M11/Nine submachine guns, as designed, have a fast cyclic rate from 900 to 1,200 rounds per minute. Despite their RPM, the little guns are amazingly reliable. One key component of any magazine fed weapon’s reliability is its magazine. For the Model 10, Mr. Ingram chose existing magazines, which in addition to insuring reliability reduced manufacturing costs. Both the 9mm and .45 caliber magazines were readily available as surplus. The management of MAC decided that they would alter the MAC and magazines, so that as-issued surplus magazines would not readily lock into the weapons, more or less forcing their customers to buy spare magazines from them.

Model 10/9mm Magazines

For his first 9mm Model 10, Ingram used surplus 32-round double-stack, single-feed British Sten magazines. Although the questionable reliability of the Sten magazines was known to Ingram, the magazines were chosen due to the request of a customer. The deal never materialized and only a handful of the Model 10 submachine guns, all 9mm prototypes, were made that used the Sten magazine.

The next magazines used for the Model 10 were those designed for use with the Swedish 9mm M/45 submachine gun. The 36-round magazines were procured from the Carl Gustav plant in Sweden, and then modified by MAC personnel to fit and function in Ingram’s submachine gun. Because of the United States’ involvement in the Vietnam War, the Swedish Government refused to allow further exportation of the magazines. With the supply of M/45 Gustav magazines cutoff, the Military Armament Corporation began importing 32-round Walther MPL 9mm submachine gun magazines from Germany. Slight modifications were made to the magazines to adapt them for fit and function in the Model 10. The Walther-type magazines were the primary units MAC supplied with the majority of their 9mm submachine guns.

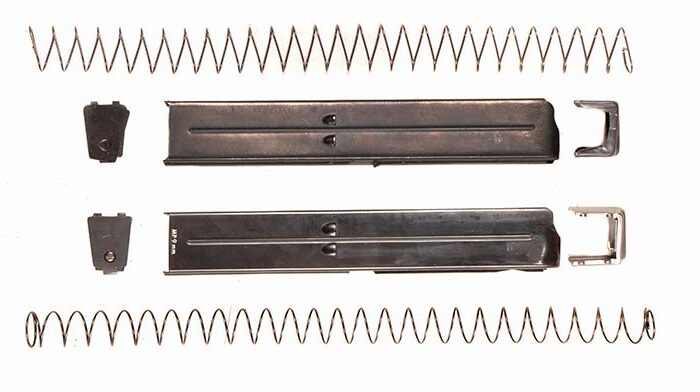

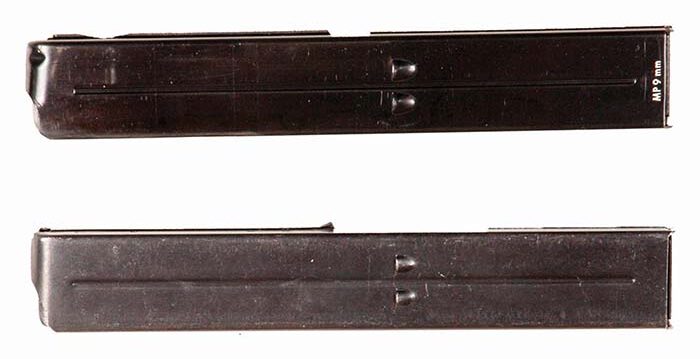

Today, original 32-round magazines for the 9mm MAC 10 can be difficult to find and expensive. The double-stack, double-feed original magazines can be identified by the “MP 9mm” or “MPL” markings located on the left lower side of the magazine body, a silver-color metal follower and an indented vertical rib on each side that runs the length of the body. The follower springs are oval or round in shape. The original magazines sold by MAC have a high-quality deep blue finish, and often will be marked with the word “MAC” over a Cobray logo with a number or letter underneath. The markings are generally found on the front edge of the magazine body. According to original MAC documents, the letters and numbers were used as controls, while testing magazines of various lots and configurations (feed lips, springs etc.) and finishes that included oxide, blue and phosphated.

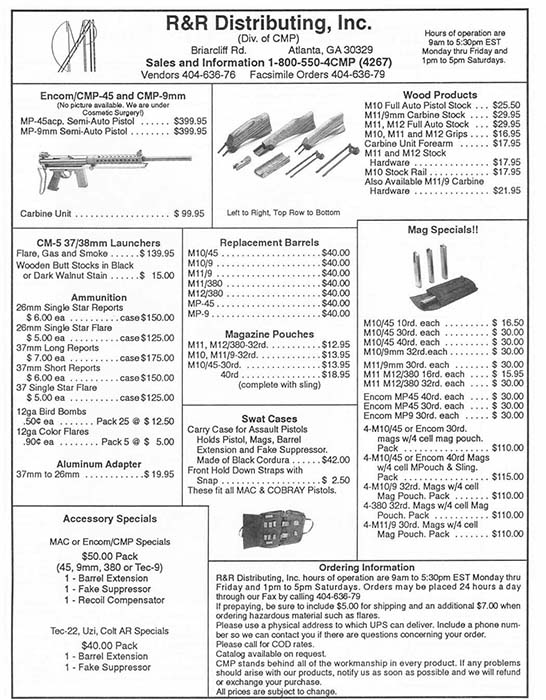

After the original MAC Corporation folded, a number of magazines were manufactured for the 9mm Model 10 by Component Metal Products of Atlanta. The company, also known as CMP, was a magazine subcontractor for both RPB and SWD. Magazines made by the Component Metal Products Company will usually have the Cobray or a stylized “CMP” logo stamped on the front edge of the magazine’s body.

Every machine gun owner has to have a LOT of magazines for their weapons. Because of the 9mm MAC 10 magazine situation a few innovative companies have devised solutions to the problem.

The Uzi Magazine Conversion

To address the shortage and expense of original Walther-type magazines for the 9mm Model 10, the Uzi magazine-well conversion was conceived. The conversion offered the MAC 10/9mm owner the ability to use the plentiful and inexpensive double-stack, double-feed Uzi magazines that are available in both a 25 and 32-round configuration. The down side of the conversion is that it requires cutting off the original magazine well and welding the Uzi grip assembly onto the receiver.

The Grease Gun Magazine Conversion

Another option for owners of an Ingram MAC 10/9mm submachine gun to address the magazine shortage/expense problem is the .45 caliber M3 “grease gun” magazine well conversion. To complete the conversion, a .45 caliber upper receiver and bolt assembly are needed. This conversion semi-permanently converts a 9mm MAC 10 to a .45 caliber configuration that uses inexpensive “grease gun” magazines. If the owner wants the option to fire 9mm rounds, there are kits available to convert .45 caliber MAC 10s to 9mm through the use of a magazine well adapter, bolt and barreled upper. The .45 to 9mm conversion kits use the Walther style magazines.

Model 10/.45 Magazines

The .45 caliber Ingram Model 10 was designed to use the double-stack, single-feed steel 30-round magazines, originally designed for the U.S. .45 caliber M3 and M3A1 submachine guns, better known as the “grease gun.” Although the single feed design has often been criticized, the prototype of the M3 was one of the few weapons able to pass the Ordnance Department’s grueling mud and dust test, which led to its eventual adoption.

For the .45 caliber Model 10, Gordon Ingram chose surplus “grease gun” magazines, but MAC management wanted them modified so that customers would have to purchase spare magazines from the Military Armament Corporation. Unmodified magazines would not lock up in the Model 10. The government surplus magazines were modified and stamped with the Cobray logo on the front edge of the magazine body by MAC workers. At times when the inexpensive surplus “grease gun” magazines were not available, the Military Armament Corporation was forced to have the MAC 10 magazines produced locally. This proved to be quite expensive, and few were made. The locally made MAC 10/.45 magazines lacked the thick sleeve around the feed lips fitted on surplus M3 magazines.

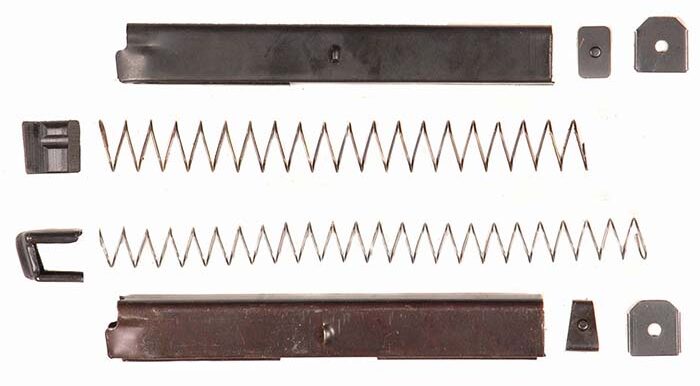

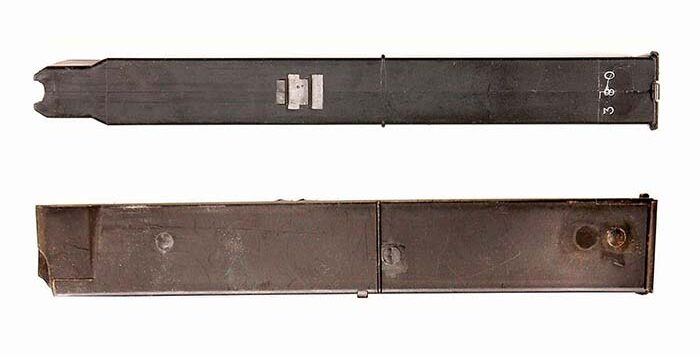

After the Military Armament Corporation bankruptcy, RPB resumed the manufacture of Model 10 and Model 11 submachine guns and associated accessories. RPB reportedly subcontracted their magazine work out to the Component Metal Products Company. During this period, CMP produced 40 and 10 round capacity magazines for the .45 caliber Model 10. These magazines will have the Cobray on them in various points on the front edge of the magazine’s body. Although they function satisfactorily, the locally manufactured magazines were of a lesser quality than the surplus GI grease gun magazines. CMP magazines were made from thinner gauge sheet metal and have stress lines on them from being formed on a mandrel; the finish was a dull blue.

SWD also used the Component Metal Products to produce magazines and related accessories, marketed and sold by SWD. Products offered by SWD will usually have the word “Cobray” underneath the Cobray snake logo.

Model 11/.380 Magazines

The .380 caliber Ingram Model 11, aka the MAC 11, manufactured by the Military Armament Corporation used proprietary double-stack, single feed steel magazines. The followers of the magazines were also made of steel. Most of the original magazines were marked on the front edge of the magazine body with the Cobray snake logo, with the word “MAC” on top and a number underneath. The MAC 11/.380 magazines were made in 16- and 32-round configurations, and have a dull blue finish. Like most single-feed designs, the MAC 11/.380 magazines are difficult to load without a loading tool. A magazine loader was available that was a scaled down version of the .45 caliber M3 grease gun magazine loader. Original 1970-80 magazines for the MAC 11/.380 can be difficult to locate and are usually quite expensive.

Most of the MAC 11/.380 magazines manufactured during the RPB/SWD days were made by subcontractor Component Metal Products. The CMP magazines were marked with only a Cobray snake logo. The magazines sold by R&R Distributing, Inc., a division of CMP, were stamped with a stylized CMP logo. The magazines were made in 16- and 32-round configurations.

Other aftermarket magazines have been manufactured, but their quality and reliability varies, particularly when considered for use in a submachine gun. Recently manufactured aftermarket magazines often have cartridge followers made of plastic. Due to the small number of Model 11 submachine guns that were manufactured, there are not as many magazine options as there are with the Model 10 and SWD M11/Nine arms.

M11/Nine Zytel Magazines

When the M11/Nine was introduced in 1983, their 30-round double-stack, single feed magazines were made of a new revolutionary “space-age” plastic called Zytel. This caused quite a bit of excitement back then, but the enthusiasm was short-lived. After firing approximately 1,000 rounds from the magazines the lips would start to wear out and eventually could no longer contain the rounds inside the magazine. Another problem was that the two-piece magazine bodies were splitting apart where they were glued together. Later SWD Zytel magazines were improved, by inserting a pair of metal “staples” at the front and back of the top of the magazine body to prevent splitting. A third generation of Zytel “one piece” magazines were introduced that seemed to solve the splitting body problem, but the feed lips were still susceptible to wear, which over time resulted in cartridge feeding problems. The feed lip problem has more recently been addressed by a company that manufactures stainless steel replacement feed lips for the Zytel magazines. The replacement lips are attached to the inside of the lips by epoxy glue. The replacement steel lips will only work on magazines that have not already been damaged by wear. The Zytel magazines have a plastic cartridge follower and most have metal floorplates. The M11/Nine magazines all have the SWD-style Cobray logo with a circle and the word Cobray at the bottom.

SWD M11-A1/.380 Magazines

The M11-A1/.380 submachine guns produced by SWD were also designed to use the Zytel magazines. Some of these magazines were marked “.380” on the back of the body. According to Wayne Daniel, the magazines were exactly the same as the 9mm Zytel mags.

M11/Nine Steel Magazines

There have been several entities offering steel magazines for the M11/Nine to replace the original Zytel magazines. Some of these are new manufacture, while others are conversions of existing magazines. The steel replacement magazines are available in several cartridge capacities.

M11/Nine Magazine Conversions

The problems encountered with SWD’s Zytel magazines created a need for a steel replacement. A perfect candidate was those made for the World War II British Sten submachine gun. Sten magazines are plentiful and inexpensive; however the Sten magazines would not fit into the M11/Nine’s magazine well. To solve the problem a larger magazine well was designed. The downside of the conversion was the old magazine well had to be cut off and the new one welded to the receiver, creating a semi-permanent alteration. In addition to cutting and welding, the firearm had to be bead blasted and refinished. There are several companies that will perform the conversion and offer the Sten magazine well separately, for those who want to do their own conversion work. However, original Sten magazines have a reputation of being less than reliable, and often require a periodic “adjustment” to their feed lips to maintain the correct 8-degree cartridge angle for reliable feeding. For those that would rather use new magazines, Sten magazines made of Polymer are now being commercially manufactured.

For those desiring even more magazine capacity then the 32-round Sten magazine offers, the 50-round magazines designed for the British Lanchester submachine gun will also fit and function with the conversion kit

Aftermarket Magazines

A magazine company called Scherer/LaPrade, based in Tennessee, manufactured a number of magazines for the Model 10 and Model 11. These magazines can be identified by their dull blue finish and lack of any Cobray or other manufacturer’s markings. The cartridge followers of these magazines were usually made of plastic. The Scherer/LaPrade made for the 9mm Model 10 can be identified by four oval witness slots on the left side of the body. Under the slots the numbers 10, 20, 30 and 36 are stamped indicating the number of cartridges in the magazine. There is also “made in the USA” stamped on the left side. The bottom floorplates have two horizontal ribs. The 36-round magazines are approximately .5 inches longer than the original 32-round Walther magazines and the fit and finish of these magazines are not up to the quality standards of the original Walther magazines. A company that has more recently manufactured aftermarket magazines for the Model 10, Model 11, M11/Nine, and their semiautomatic counterparts, is National Magazine, Inc. These magazines generally have no markings on them, have smooth bodies and plastic followers.

The Good News

Knowing of the magazine availability problem of the 9mm MAC 10, Russell Weeks of RPB Industries (not directly related to the defunct RPB of old) decided to produce reliable magazines for the 9mm Model 10. SAR procured some of the magazines for function testing from Russell at the recent Knob Creek shoot. The new magazines appeared to be well-made and differ slightly in appearance from the original MAC/Walther magazines. Stamped from the original dies, the RPB magazine body is a dull blue color and the follower is blued. The RPB magazines functioned flawlessly in the test weapon, a 1972 manufactured Powder Springs Model 10. The good news for 9mm MAC 10 owners is the new magazines are affordable and they work.

More Good News

In addition to the 9mm MAC 10 magazines, RPB is now offering magazines for the MAC 11/.380 formed on the original dies. The magazines procured for testing fit and functioned perfectly. Like the 9mm magazines, the .380 mags are finished in a dull blue color. One slight difference is the new manufacture magazines use a plastic follower. The magazines are for the .380 caliber Powder Springs MAC 11 and RPB MAC 11A1. They will not work in an SWD M11-A1 originally designed for the Zytel magazines.

For .45 caliber Model 10 owners there is a replacement magazine catch that allows both MAC modified and unmodified M3 grease gun magazines to be used. The old catch is easily replaced by simply removing the rear plastic grip panel and pushing out the retaining pin.

Drum Magazines for the MAC

Firing a standard capacity box magazine from a MAC-type submachine gun is a thrilling – but brief – experience. For those desiring more firepower, there have been several high-capacity drums available for the MAC. Over the years there have been several companies offering drum magazines. The MAC drums are conversions of existing drums, originally made for other submachine guns. One of the most popular drums used for the conversions are those made for the 9mm Suomi submachine gun. To adapt the drum to a 9mm MAC, an extension is needed to feed the rounds up through the pistol grip. The reliability and quality of such conversions relied on the skill of the company performing the work. Some of the better drums were made by C&S Metall Werkes, Ltd.

More recently, the BARRELXCHANGE Company has successfully designed and built a high-capacity drum for the .45 caliber MAC 10. Again using the Suomi drum as a host, a feed tower was fabricated from a MAC 10 (U.S. M3 grease gun) box magazine and attached to the drum’s body with four Allen screws. The drum can be loaded with up to 50 rounds of .45 ACP cartridges. The drum will also fit and function in a U.S. M3 or M3A1 submachine gun. BARRELXCHANGE also offers a feed tower to adapt the MAC drum to fit and function in a Reising submachine gun.

Sources

RPB box magazines for 9mm MAC 10 and .380 caliber MAC 11:

www.gunmallusa.com/gunmallusa/prepareInventory.do?cat=55&storeNumber=1

BARRELXCHANGE MAC drum magazines: http://barrelxchange.com/

This article was excerpted in part from the book: Gordon Ingram, the MAC MAN

| This article first appeared in Small Arms Review V17N2 (June 2013) |