By Charles Brown

The problem of muzzle flash and smoke has bedeviled warriors ever since the Chinese invented gunpowder. Black powder combustion is accompanied by a flash, some sparks and the release of large volumes of white smoke obscuring both the shooter and the target. France was the first major power to develop a replacement for traditional black powder and field a smokeless powder small bore rifle with the introduction of the 8mm Mle. 1885 Lebel. The propellant was “smokeless” only to the extent that it smoked less than black powder. This caused France’s current worst enemy, Germany, to develop an even more efficient smokeless propellant with a much reduced flash signature. Not only did Germany develop a better propellant, but also flash suppression devices for their automatic weapons.

The advent of large scale use of automatic weapons in WWI trench warfare drew considerable attention to the muzzle flash issue. While it would not be worthwhile to single out individual riflemen firing from entrenchments, the large volume of harassing fire from machine guns was a different story inviting counter battery fire from artillery. This development made machine gun troops something less than popular with riflemen occupying the same trench area. During low light conditions muzzle flash will compromise the operator’s night vision as well as making the location of the weapon more visible to the opposing forces.

The standard German automatic weapon was the MG 08/15 featuring a combination flash suppressor/recoil booster as standard equipment, the U.S. Model of 1917 water cooled machine gun featured nothing in the way of a flash hider except the ingenuity of the troops draping wet empty burlap sand bags over the business end of their Brownings in an attempt to attract less unwanted attention.

The Ordnance Department, up to its neck in every sort of difficulty during WWI, worked on developing a flash hider with little enthusiasm and less success.

Post-war the flash hider issue came to a head with a letter from the Adjutant General’s office to the new Chief of Ordnance Major General Clarence C. (“If the troops want elephants, we will get them elephants.”) Williams read for record into the Ordnance Committee’s November 4, 1919 meeting minutes. This letter enumerated “…machine gun improvements…” which were the “…consensus of opinion of our best machine gun officers…” and closed with a directive from the Secretary of War that the improvements suggested be “…carried out as far as practicable.”

High on the list was “Development of an efficient flash hider; flashless powder is not considered to be sufficient.” This was followed by requests for “Real smokeless powder and, if possible, a flashless powder is needed. Our powder is far from smokeless and discloses the position of the guns at once.” The letter stirred up a hornet’s nest of activity in the Small Arms Division as they tried to determine which of the “suggestions” had been carried out or were under research or actual development.

Apparently some flash hider development had already occurred because at the November 14, 1919 Ordnance Committee meeting they considered a report from the Springfield Armory on a flash hider and recoil reducing device for the Model of 1917 BMG designed by a Captain Thomas of the Ordnance Department. The report stated that this was the fourth flash hider of the “Thomas type” tested and that all had proved unsatisfactory and recommended no further testing of this design be made. The May 14, 1920 Ordnance Committee meeting shed more light on the shortcomings of the Thomas design: first, it did not suppress the muzzle flash and second, it was shot off the gun after extended firing.

Apparently the flash hider issue got pushed to the back burner until the Committee took up as Item 1966 a December 6, 1921 communication from the Infantry Board requesting that a project be initiated to study and develop flash hiders that actually worked. Mr. A. C. Gray, a civilian employee of the Ordnance Department, stated that he had seen several types of flash hiders and that “The German one (ostensibly the MG 08/15) reduced the flash by about 50%.”

Things picked up a little momentum. The September 15, 1922 meeting of the Committee discussed Item 2368, a flash hider design by Captain A. F. Gilmore of the Coast Artillery Corps, which was somewhat similar to the Thomas design and, while it was efficient enough, it was expensive to manufacture and suffered from the same basic defect, it shot off the gun because it plugged up after prolonged firing. Major Glen Wilhelm who read the report mentioned that Springfield Armory had “perfected” a new type that would be submitted to test in the “near future”. By November 1922 approval was obtained for “one modified German flash hider” together with one of the Springfield Armory type to be submitted to the Infantry Board for testing.

The March 23, 1923 Committee meeting reviewed as Item 2774 the report of the flash hider testing from Aberdeen Proving Ground. The conclusion of the proof officer, approved by the Commanding Officer, was that the modified German flash hider “gave the best results, and was superior in every way.” However, in a dazzling display of fancy foot work and buck passing, Aberdeen stated that “in view of the fact that the flash hider designed by the Springfield Armory gave fairly good results and in consideration of a statement from Manufacturing Services (Springfield Armory) to the effect that the cost of Springfield Armory type would be considerably less than the German type, it is believed that both flash hiders should be tested by the Infantry…”

By the July 27, 1923 meeting of the Committee the story had changed somewhat. Item 3149 considered at this meeting stated in part, “These flash hiders have been tested at Aberdeen Proving Ground and by the Infantry Board with results that show very little difference in efficiency, while both are very good.” The Infantry Board recommended adoption of the Springfield Armory type apparently based on cost and the fact that it was an indigenous design never minding the fact that the “German” type was superior.

The December 27, 1923 Ordnance committee meeting took up Item 3462 which was specification No.52-5-12 the flash hider for the Model of 1917 BMG. This specification was approved and result was the M1923 flash hider. The shooting off of the flash hider problem was solved by removing the muzzle gland from the end cap of the water jacket and screwing in the flash hider.

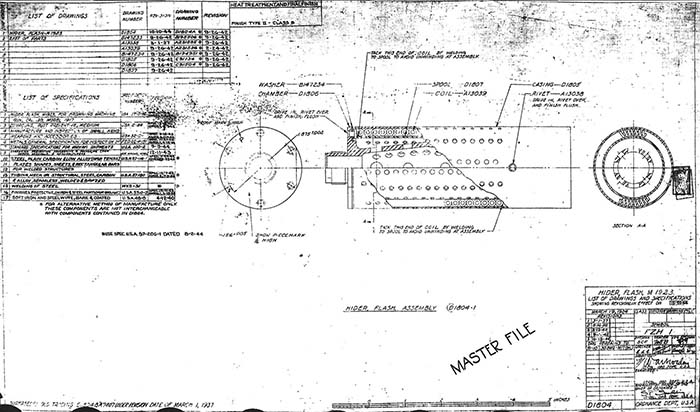

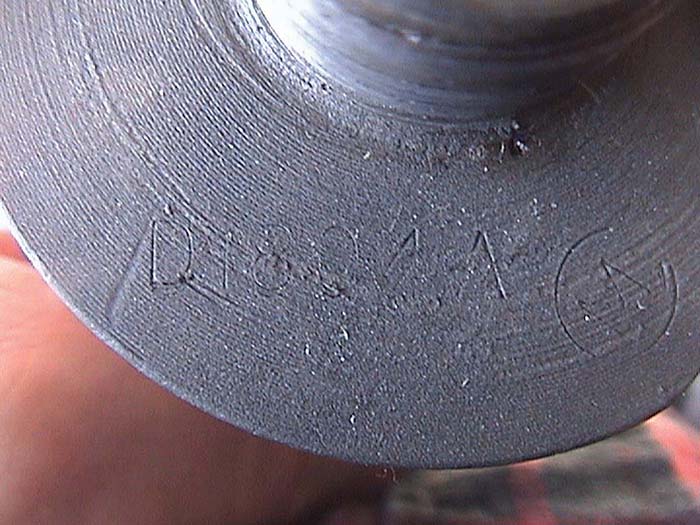

The M1923 flash hider resembled previous designs except that it had vent holes in the exterior and functioned by allowing the unburned combustion gasses from the propellant to swirl around a series of baffle holes between the chamber that the projectile passed through called the inner spool and a helically wound coil spring between the spool and outer casing finally venting into the air. This allowed cooling and gradual mixing of the residual combustible gas with oxygen in the air. The flash hider was piece marked with the drawing number D1804 and underwent a proof test signified by the “P” stamped on the rear. It appears that all of the M1923 flash hiders were produced at Springfield Armory until RIA became the Ordnance primary engineering support and production facility for the .30 caliber BMG’s about 1936. Although not often seen actually on the weapon, the M1923 was a standard accessory for both the Model of 1917 and its successor the M1917A1.

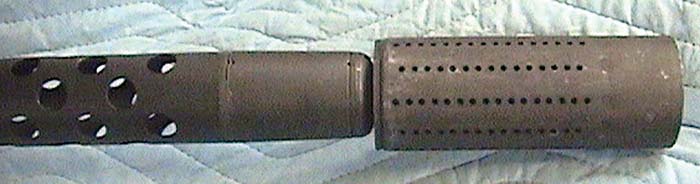

RIA produced experimental flash hiders for the .30 caliber air cooled BMG’s during WWII including an attempt to adopt the M1923 flash hider to the M1919A4. This whole series of “beer can” styles all suffered from the same defects. They were relatively large and difficult to maintain as the vent ports plugged up with carbon deposits after extended firing. Plugged vent ports would increase booster chamber pressure raising the rate of fire and the specter of damage to the air cooled weapons because their gas assist booster feature not present in the water cooled gun. In February of 1942 in an attempt to speed production an alternate design for the M1923 flash hider was developed its drawing number and piece mark was D1804A.

At least one, and likely several of this type were modified and attached to a M1919A4 barrel jacket by means modified front barrel bearing plug and sent to Aberdeen Proving Ground for testing in 1943. The tests were not successful and in 1954 a left over jacket, bearing and flash hider showed up in a scrap barrel in a salvage yard behind the Proving Ground Museum where it was rescued by Jon Wilkinson, a member of the 9701st Technical Service Unit stationed at Aberdeen.

The story of this find related to the author by Mr. Wilkinson goes like this: Jon saw the parts in the scrap barrel thought they looked unusual and wanted them. The guy running the scrap yard told him that the barrels were pre weighed for sale as scrap, and if he wanted anything he would have to come up with an equal weight in steel for replacement. Jon and his buddy Val Forgett, yes, the Navy Arms Val Forgett, were leaving the post that day and noticed some railroad track construction underway so they stopped and filled the trunk of the car with tie plates to swap for parts that they wanted from the scrap barrels. John displayed the A4 jacket/flash hider at an Ohio gun show in March of 2012 where Jeff Prater of Iron Creations, LLC spotted it and decided it needed a new home. Jeff took some pictures and sent them off to the author. You just can’t make up stuff like this.

Eventually, RIA’s flash hider R&D focused on the fairly obvious, the cone feature of the MG 08/15. The cone shape tended to minimize and direct the flash to the front of the gun, reduce the low light ball of flame display and somewhat diminished visibility of the flash from the flanks. The troublesome and complicated baffles and vent holes were eliminated.

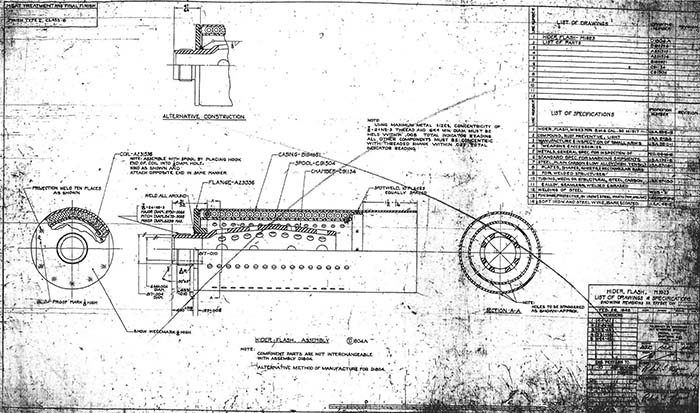

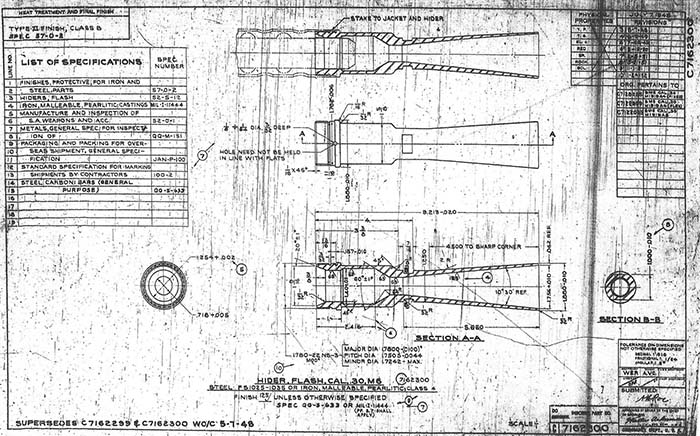

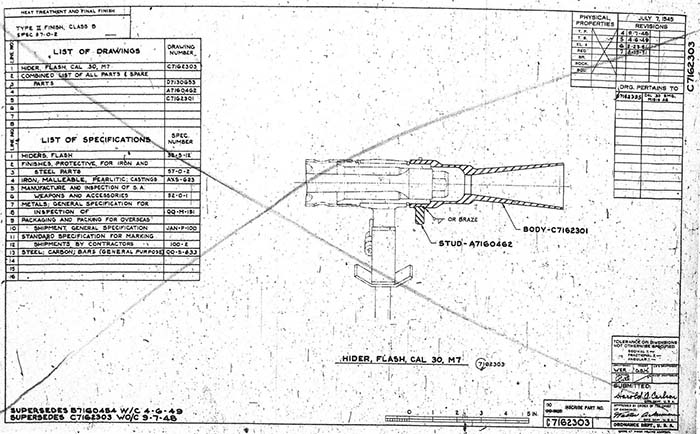

The M6 design for the M1919A4 Fixed and Flexible models which would also fit the M1919A5 included an integral front barrel bearing and a booster chamber eliminating the one or two piece front barrel bearing and muzzle plug and screwed directly into the barrel jacket staked in place with the usual band (lock ring). The M7 flash hider for the M1919A6 replaced the cap style booster and the M8 design for the M1917A1 water cooled gun used a modified muzzle gland with the double male threads rather than the original gland. The drawings for M6 and M7 have an original date of July 7, 1945. It is not likely that any of these ever made it into combat in WWII. All of the cone style flash hiders could be machined from steel or cast from perlitic malleable iron alloy commonly called ArmaSteel, Saginaw Steering Gear’s Malleable Iron Division trade name.

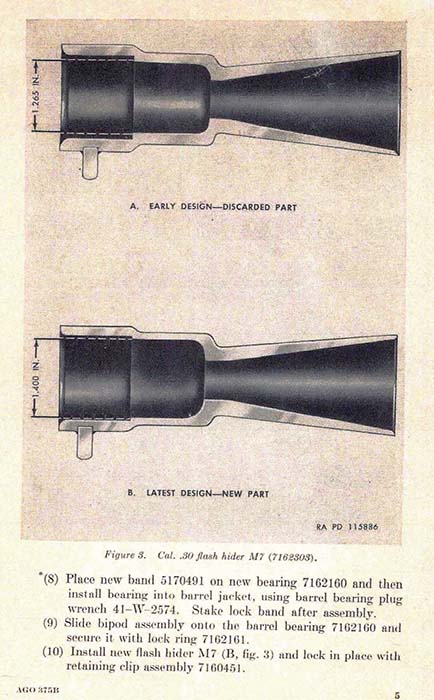

A good portion of RIA’s immediate post WWII activity involved the overhaul and refurbishing of all manner of equipment, especially small arms, and preparing them for long term storage. This required the production of replacement and maintenance spare parts which they were doing in house. M6 and M7 flash hiders were being produced in small quantities as early as 1947. While the M6 design remained virtually unchanged throughout production, the original M7 design with a booster chamber diameter of 1.265 inches was apparently causing reliability issues in the M1919A6 so the chamber diameter was increased to 1.400 inches in August of 1948.

The first mention of any mass production of M6 and M7 flash hiders comes from RIA’s Manufacturing History for Fiscal Year 1950 (1 July 1949 to 30 June 1950) which also mentions R&D on an aluminum .30 caliber flash hider but does not indicate what .30 caliber weapon it was for. Fiscal Year 1950 flash hider production was 17,990 M6 and 8,961 M7 flash hiders followed by 10,900 M7’s in FY 1951, 14,014 in FY 1952, 19,194 in FY1953 and 3,277 unidentified types in FY1954.

In August 1949, the War Department issued a Modification Work Order (MWO) to replace all M1919A6 cap style boosters, M7 flash hiders with the 1.265 inch booster chamber, front barrel bearings and bipod retaining rings that were in the field with the new M7 having a 1.40 booster chamber and a redesigned front barrel bearing and thicker retaining ring. The MWO did not cover weapons in storage and for reasons not known the MWO was rescinded by Department of the Army Circular 310-66. The M6 flash hider is supposed to be marked 7162300 following the drawing/parts number naming convention adopted in late 1943 for new parts for either an existing or new weapon. Some M6s are mismarked C7162300 due to widespread confusion about including the drawing letter size in the imprint on the part. Birtman Electric Company produced M6s usually have the number near the open end of the cone, RIA production on the booster section. M7s are marked with the 7162303 drawing/part number there maybe mismarked C7162303 flash hiders lurking out there. Maker’s markings were not required. M6s have the standard .718 booster orifice and M7s the .812 opening, both designed for U.S. Caliber .30 ammunition. The M6 has 1 inch wrench flats at the base of the cone to aid in removal.

When the Korean War started RIA farmed out some M6 production to Birtman Electric Company, a Chicago firm that manufactured home appliances and had a production facility in Rock Island, IL. Packaged M6 flash hiders with Birtman labels are quite common, usually found with packing dates from 1951 to 1953. M6 packaging included a new band (lock ring) as the bands were not intended for reuse after initial staking. Birtman also produced 3.5 inch M20 rocket launchers (bazookas) along with toasters and vacuum cleaners. The company was purchased by Whirlpool, the appliance maker, in 1957. Every time the author loads the dishwasher, the heritage of the bazooka and the M6 flash hider makes pushing the start button much more interesting.

While the M6 and M7s were manufactured in quantity before, during and after the Korean War, most of the official wartime photos seen by the author do not show either of these parts. Documentation after July 1957 gets rather sparse as the air cooled BMGs were being elbowed out of the way by the M60GP machine gun and the primary source of Browning information, RIA, and by association the RIA Museum, lost engineering support and manufacturing oversight for machine guns when this responsibility shifted to back to the Springfield Armory.

The last official documentation known to the author of the air cooled BMG’s are the 1970 Depot Maintenance Work Requirements (DMWR) produced by the Army Weapons Command at RIA and the 1969 TM9-1005-212-25 for the M1919A4, M1919A6 and arguably the best of the breed the M37. These publications show only the M6 and M7 flash hiders as component parts, the M37 continued to use a booster bearing arrangement lacking any flash hider. Why the Army continued to produce a document, the DMWR, related to inspection and overhaul of a weapon displaced 17 years previously in combat ready units is not known.

| This article first appeared in Small Arms Review V17N2 (June 2013) |