by Bob Pilgrim

TALL TEXANS

Back in the very late seventies, I had the privilege of meeting two “tall Texans.” They weren’t tall in physical stature, but were mighty big in countless other ways and were particularly large in the area of firearms innovation. While conducting SWAT training for the Houston, Texas Police Department, I was introduced to a nasty, chain-smoking entrepreneur who got in everyone’s face, but was generous to a fault and had a heart of gold. I saw him give my buddy’s kid a “Texas Check Book” filled with dollar bills that you could tear out like checks. I don’t know how many bills were in that pad, but it was a princely sum for that little boy, who grew up to be a US NAVY cryptologist and aspiring FBI agent. Since then, Herman Mueschke, former lieutenant and SWAT team leader for Jacinto City, Texas police department, Special Deputy US Marshal and president of Mueschke Manufacturing Company has stopped smoking, but still looks as tough as a Texas tumbleweed. Herman also fought with the Fighting 59th in Europe during World War II and was on his way to Tokyo when the Atom bomb was dropped. He started a glass and mirror company from scratch (no pun intended), but his first love and persistent passion is repairing and improving firearms, metal plating and creating components for various manufacturers’ lines of firearms. Smith & Wesson for example, was once a big customer of his. Eventually, he treated a number of my pistols, but the one that literally remains closest to me is my diminutive, but handy Beretta .25 ACP pistol. He was literally a ball of energy, while engaging in dozens of unique firearms related projects.

HILL 15 SUBMACHINE GUN

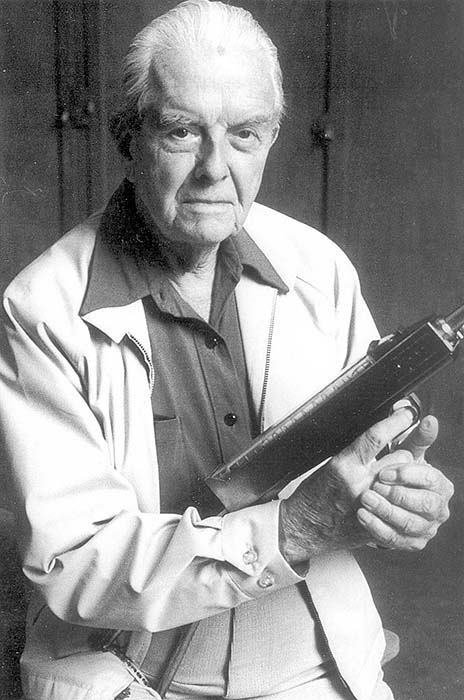

Herman, who shared my interest and love of firearms, took me over to Mr. John L. Hill’s residence to meet him and see his creation, the Hill (H15) 15 submachine gun. John, who at age 96 passed away in 1991, was an American petroleum engineer and former World War I fighter pilot for the Royal Canadian Air Force. In his spare time he was an inventor and designer of many energy connected technologies including a method for compressing gas, so it could be shipped from the well in containers without a pipeline. His patented process is still being used in shipping gas overseas today. Although his parents were surprised and chagrined when they learned that he had not matriculated into college as planned and became a fighter pilot instead; this self-educated engineer supervised many technical projects in country’s as diverse as Canada and Argentina. However, he always had a fascination with firearms, not so much in shooting them, but the mechanism. In 1948 he began thinking of the Hill Machine Gun. Hill conceived the H15 during a paralyzing Denver snowstorm in the 1960s, while he was searching for oil properties. His apartment contained a small machine shop with a milling machine that was ensconced in a closet and it was here that he transformed an idea into reality, “while Mrs. Hill sat rocking and knitting in a corner.” His personal industry and ability impressed upon me that in spite of draconian gun laws and prohibition, underground small arms could be produced by anyone with the knowledge and desire to do so. Hill was a consummate patriot and his motivation was simply to build a “better mousetrap” for America’s defense.

He unveiled a couple of full-automatic-only examples of the H15 in 9x19mm and .380 ACP and discussed their characteristics. After a very pleasant visit with the gentleman we departed with the guns for test firing at Herman’s factory. Years later, Herman and another business partner purchased the patents for the H15, which have expired.

F N’s GOOD FORTUNE

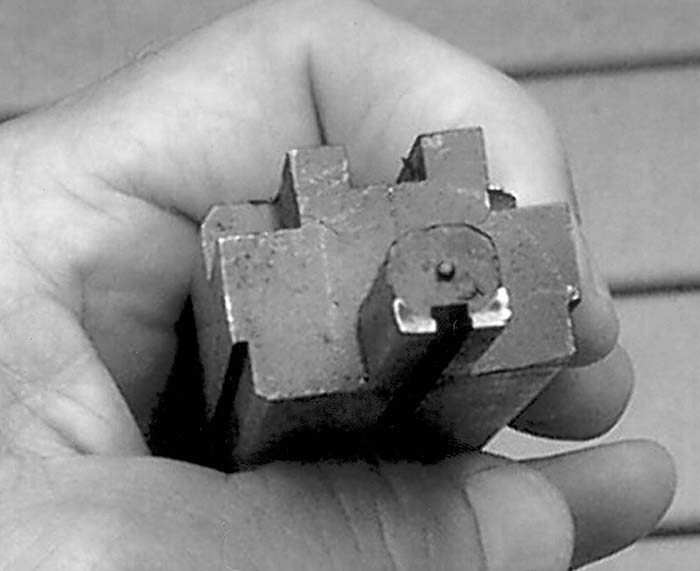

The H15 resembles a large pistol and in fact, has the pointability of the famous German Luger. Depending on interchangeable barrel lengths, the gun is an extremely compact submachine gun (SMG). Its profile is characterized by an extended slide that projects rearward, so it lies over the forearm, in the manner of the IMP .224 Bushmaster aviator’s survival weapon that debuted in the 1970s. Construction is entirely in stainless steel and they are handsomely finished. In addition to no externally moving parts and round ejection through its grip, one of its most striking features is its transparent plastic, “desmodromic – oscillation feed” magazine that sits in top of the receiver. Rounds are transported in a lateral position and steered into the chamber by a “revolving disc.” Chambering is straight into the barrel without any deflection. The barrel’s throat reflects this and is not ramped or chamfered.

Herman recently revealed that in 1963, Mr. Val Browning, Chairman of the Board, Browning Arms Company arranged for Hill and his wife to visit Fabrique Nationale d’ Armes de Guerre, in Belgium. Monsieur Ernest Vervier hosted them in Liege. Hill left the H15 prototype with FN for a couple of years, but before he departed they requested that he produce a 9x19mm version for them. Although very interested in manufacturing the gun, Uzi Gal was also at the factory supervising FN’s production of the UZI SMG. He was very impressed when he examined the H15. FN could not generate customer interest in it and dropped the project in 1965. When FN eventually returned the prototype US Customs intercepted the shipment and had the gun destroyed.

Obviously, the H15 and its unique magazine / loading system pre-dated production of the FN P90 SMG / Personal Defense Weapon by over three decades. Like the H15, the P90 also ejects its spent cases downward, so they do not interfere with the operation of the gun.

Herman also advised me that 90 – 100 guns were made and only ten completed guns exist today. They were on display at a private Texas museum, but were removed when some special interest groups pressured the owner to do so. Mrs. Hill, now in her nineties, further advised that the Frankford Arsenal in Philadelphia, PA also acquired an H15, but is unaware of its status today. The arsenal closed in 1975.

ATF required that newly minted models be restricted to single fire and fire from a closed bolt. No manual safeties were involved in the original guns, but Herman developed an ambidextrous system that locked the trigger. However, these H15s never went into production.

UNIQUE FIRING SESSION

All our familiarization was conducted at short range, because the factory floor was fairly crowded. A residential area also bordered Herman’s place, but the neighbors didn’t seem to mind as we blasted away. Truthfully, I think everyone was afraid of the local wild man and knew better than to complain. The H15 is cocked via a relatively small, but ergonomic non-reciprocating charging lever located on its left side. Older models had a neat folding lever located under the barrel that would snap out of the way when released. In close quarter battle applications the SMG was accurate and highly controllable. It’s 400 to 500 rpm cyclic rate chugged away like an M3 Grease Gun and single taps could be easily achieved with trigger control. I fired it with one hand and six-round bursts from 7 yards were centered on the target. Reliability was flawless, but the piece de resistance was when Herman unceremoniously rolled the H15 up in a blanket and emptied the magazine. The blanket smoldered and smoked, but fortunately did not catch fire. With a small canvas bag attached to the pistol grip, no incriminating shell casings were left behind for the gang from CSI. Apparently this feature was not lost on the godfather’s gang and Mr. Hill was approached by a “deal you couldn’t refuse.” His terse reply was simply, “Herman, we don’t want any dirty money.” With no externally moving parts or controls, it is a perfect ambidextrous firearm. We consumed about 200 rounds of hollow points that day and its “straight line feed / chambering” is capable of digesting any bullet configuration, including “caseless ammunition.” At the time, Colt Industries advised Mr. Hill that they could manufacture the H15 for $30 – $40.

UNIQUE MAGAZINE

Since the optional factory pre-loaded, or field reloaded magazine enjoys a prominent place in contemporary small arms offerings today, the H15’s deserves a closer look. It forms an integral part of the receiver, with capacity (length) limited by the length of the weapon. Since the materials are relatively inexpensive, the magazine could be pre-loaded and was disposable. Furthermore, in the interest in a “cleaner battlefield,” the body could be made of bio- degradable materials. When sealed at the factory and in place on the weapon, land and sea combatants would find the SMG or carbine “completely dirt free and watertight.” The magazine is not exposed to the usual stress forces when in battery and is therefore, more durable. When inserted from rear to front into the receiver, the aluminum cap that seals the magazine is stripped off and the first round feeds into the chamber. However, if a loaded magazine is removed from the SMG, the rounds will be ejected.

UNIQUE SAFETIES

Herman experimented with various ambidextrous safety designs and the two he incorporated in the H15 are truly unique. A cross bolt, ambidextrous safety is safe if it is maintained in a center or middle position. If pushed to the left by a right hand shooter it will fire and likewise if a left-handed shooter moves it to the right. Oddly, a sliding port and starboard safety is on safe when it is in the forward position and off the trigger lock when pulled to the rear. Herman was quick to admit that this was an off-the-wall concept and strictly experimental.

WHEN UZI WAS KING

During the 1970s, the Israeli UZI enjoyed the same reputation as the Heckler & Koch MP5 does today. The UZI was the SMG of choice in knowledgeable circles and naturally, everything in that weapon’s genre was compared to it. The UZI has a 10.2-inch barrel, one of the longest in its class. With its “snub,” 8-inch barrel in place the H15 is 3.3 inches shorter than Uzi Gal’s creation. One of the most reliable SMGs, the battle proven UZI weighs a hefty 7.7 pounds, while the Hill comes in at 4 to 5 pounds unloaded. Cyclic rates are similar.

Like the UZI, barrel changes can be accomplished without tools. H15 combat kits can have various barrel lengths and dedicated suppressed versions. Most SMG’s feature an exposed charging lever/handle and some reciprocate. The H15 charging handle operates independently from the bolt; therefore, there are no externally moving parts.

THE FUTURE AND CONCLUSIONS

Did the Hill 15 have any faults or shortcomings? Well, it would not reliably function turned upside down. Furthermore, gravity would probably not assist ejection if also fired from a horizontal position. Although some test protocols call for this maneuver, I am not aware of too many situations where that would be required. The one exception is the dog and pony show inverted window shot, from the face forward “Australian rappel.”

Unless some large arms manufacturer or the government steps forward and revives the weapon it is doubtful that it will ever see service. There are some companies without an SMG or assault rifle and an updated version of this firearm would fill that production vacuum nicely. Otherwise, the H15 may have no service future. However because of its very limited production, Class III weapons collectors will probably salivate over the possibility of acquiring a completed and functioning Hill 15. I would and am.

| This article first appeared in Small Arms Review V7N6 (March 2004) |