By Frank Iannamico

The Smith and Wesson Company (S&W) of Springfield, Massachusetts, is well known for producing some of the finest revolvers in the world. Many of them, like the .38 caliber Victory Model and the M1917 .45 caliber revolver served the Allies with distinction during World War II. During the war, S&W also tried its hand at producing a few 9mm carbines for military use; first in 1939 and then again in 1945.

The Smith and Wesson Light Rifle 1939

Prior to the United States’ entry into World War II, A 9mm firearm designed by Edward Pomeroy was submitted by Smith and Wesson to the Aberdeen Proving Ground, Maryland. The company requested that the gun be given a test sufficient to determine the practicability of their design, and to reveal any weaknesses that could be overcome with the projected manufacture of the weapon in .45 caliber.

A prototype weapon was received from S&W at the Aberdeen Proving Ground and was inspected, photographed and subjected to testing 28 November 1939. The Smith and Wesson submission was a 9mm blow-back operated, semiautomatic-only firearm that was fed from a vertical twenty-round box magazine inserted from the bottom of the weapon. No compensator or muzzle brake was fitted since there was no provision for full automatic fire. One hundred twenty rounds were fired to test general functioning, and forty additional rounds were fired after the gun was subjected to an informal dust test. The dust test consisted of simply covering the weapon with dust and dirt picked up from the firing range. After the weapon was covered with dust, it was found that the trigger was difficult to pull. One of the unique features of the weapon was its extraordinarily large (wide) magazine-well that caught and contained spent cartridge cases.

Post-firing inspection indicated that further testing would be justified if the weapon were redesigned to fire standard U.S. .45 caliber service ammunition and a provision for full-automatic fire were added. Other mechanical changes were also suggested; one was being able to reduce the force in which the firing pin strikes the primer. It was recommended that further testing be justified if the weapon was resubmitted with the suggested modifications. The Smith and Wesson Company did not submit such a gun for test.

The Smith and Wesson Company did manufacture a weapon very similar to the one submitted to the Ordnance Department in 1939. The Smith and Wesson Light Rifle Model 1940 in 9mm caliber was produced under contract with the British Purchasing Commission office in New York City. The weapon was well-made of high quality materials and proved to be quite expensive to manufacture. An improved Mk II model of the Light Rifle was introduced that featured a heavy sleeve over the bolt handle area for additional support; the sleeve also rotated to serve as a safety device. After a brief manufacturing run at the Smith and Wesson facility, all of the tools and dies for manufacture of the carbine were sent to Great Britain. Reportedly, just 1,010 of the weapons had been built and most were subsequently destroyed during World War II.

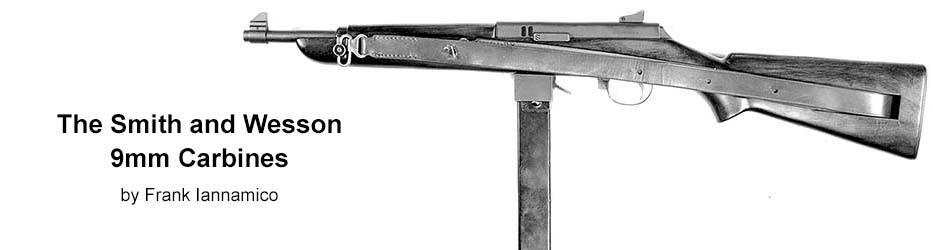

The Smith and Wesson Carbine 1945

A few years later in 1945, another new prototype 9mm carbine was built by S&W and was submitted to the Ordnance Department for testing. Because the weapon was chambered for the 9mm cartridge it is suspected that the market they expected to target was Europe. The standard pistol and submachine gun cartridge of the United States at the time was the .45ACP round. In past U.S. testing of potential military weapons, they were not seriously considered unless they fired the .45 ACP round. Any weapon expected to be accepted by the U.S. would have to have been chambered for the .45 cartridge.

Regardless of the 9mm chambering, the Smith and Wesson was submitted to the Ordnance Department for testing. The weapon was examined by ordnance personnel and then forwarded to the Aberdeen Proving Ground. On 14 May the weapon was delivered to Aberdeen by representatives of the Smith and Wesson Company: Mr. W. L. Riley and Mr. J.A. Norman. The test was conducted from 14 May to 17 May 1945. In addition to the Smith and Wesson representatives witnessing the tests were U.S. Army Colonel C.L. Hallam, Field Artillery Liaison Officer at the Ordnance Research and Development Center, Lt. Colonel R.B. Jones, Infantry Liaison Officer and Captain E. Ballinger from the Office of the Chief of Ordnance.

The first step in any weapons’ test at Aberdeen in the 1940 era was to disassemble the weapon for study and take photographs of the subject firearm in different phases of disassembly. One of the first items noted in the official report was that the weapon was, “Chambered in 9mm a cartridge, which although used extensively by foreign countries, is not employed in U.S. military weapons.”

The primary object of the test was to ascertain how the weapon would perform under the varied conditions of the standard Aberdeen light rifle test.

The Smith and Wesson 9mm carbine operated on the locked breech inertia principle. A clearance of approximately .020 of an inch was provided between the bolt lock and lock cut-out in the receiver. When the cartridge was fired, energy was imparted by movement of the lock in its cut-out, which moved it to the rear. After approximately 3/8 of an inch of travel, cam cuts in the slide retracted the bolt lock from its recess in the receiver, and remaining energy carried the assembly to the rear, completing the normal recoil cycle of extraction, ejection, and cocking the hammer. Energy stored by the compressed operating spring returned the bolt to battery, stripping the next cartridge from the magazine, chambering it and forcing the bolt lock back into its locked position. The bolt lock blocked any forward movement of the firing pin until the lock was in the locked position. This prevented the weapon from being fired when the bolt was out of battery.

The manual safety of the weapon was conveniently positioned inside of the trigger guard similar to the safety of the M1 Garand rifle. The safety acted as direct hammer, sear and trigger block when moved to a rearward position. The receiver was suspended in the wooden stock at two points; the recoil plate and the receiver latch. The weapon’s barrel was free floating and did not contact the stock, foregrip or handguard. The trigger housing and its components were secured to the receiver by a trigger guard similar to the one on the M1 Garand service rifle. The rear sight was of the aperture type, which was adjustable for windage and provided settings for 100 and 300 yard ranges. The barrel mounted front sight was a simple post-style.

The weapon was equipped with an adjustable leather sling. The sling was attached to the weapon on the left side of the buttstock and to the front barrel band. The overall length of the S&W carbine was 30.5 inches the stock length was 28 inches. The overall length of the barrel was 12 inches. The twist of the 6-groove rifling was 1 turn in 8.75 inches. The carbine weighed 6 pounds and 8.38 ounces with sling and empty magazine.

The weapon was designed to use the double stack, single feed box magazine from the British Sten submachine gun. The Aberdeen report stated that the weapon could also accept and function with the thirty-round M3 9mm conversion magazine, which were Sten magazines; although there was a contract to manufacture the M3 conversion (Sten) magazines in the United States.

The Smith and Wesson carbine was easily field stripped by unscrewing the front sling swivel and sliding the front band forward, after which the barrel, receiver group and trigger group could be separated from the stock. The carbine was able to be field stripped in twenty-nine seconds and reassembled in fifty-seven seconds. Complete disassembly took one minute and forty-six seconds. Reassembly required four minutes, twenty-two seconds. It was noted in the report that a tool (a small screwdriver) was required to remove and replace the ejector.

Although the carbine tested was semiautomatic only, a similar select-fire version was reportedly undergoing development at the factory, but was not quite ready for testing.

One hundred rounds were initially fired to check the subject weapon for proper operation and a total of 4,652 rounds were fired during the three-day test.

During the test, the extractor fractured after 1,285 rounds and the firing pin fractured after 3,324 rounds were fired. The muzzle flash observed in low light conditions was approximately four inches long and three inches in diameter. Sparklers were noted at both the muzzle and breech. Performance during the rigorous Aberdeen mud and dust and rain test was good. General overall performance was considered good, with the exception of a few failures to fire (mostly from light primer hits) and failure of the trigger to recover. Failures of the trigger to recover were found to be the result of a roughly machined sear and too close of manufacturing tolerances. Both malfunctions were considered to be minor and could be easily corrected.

After the test was completed an official Ordnance Department report was complied that stated that the Smith and Wesson carbine was simple in construction and could be manufactured at low cost. The U.S. Ordnance Department recommended that no further testing of the Smith and Wesson carbine was justified due in part to a lack of a requirement for a weapon of its type, and the anticipated end of the war.

| This article first appeared in Small Arms Review V8N10 (July 2005) |