By Jonathan Ferguson

Armament Research Services (ARES)

This experimental British light machine gun or automatic rifle was developed from 1945–1947 under the auspices of the British Armament Design Establishment (ADE), based at the former Royal Small Arms Factory Enfield in North London. It was therefore the first true Enfield bullpup firearm but is poorly understood today. This is not helped by the baffling duplication of “EM,” or “Experimental Model,” designations by ADE (see “A Note on Nomenclature,” below). This leads to confusion with the later E.M.1 assault rifle. The original E.M.1 was designed by Roman Korsak (frequently rendered “Korsac”) alongside a 7.92 x 33mm assault rifle designed by Jeziora?ski (often misspelled as “Jesieranski” or “Jeziorenski,” including in official documents of the period)—the first British weapon to be designated E.M.2 and not to be confused with the more famous Janson E.M.2.

Korsak was a Polish refugee—one of a number of Belgian, Czech and Polish weapons designers, including Jeziora?ski and Janson; the latter’s birth name being Januszewski—who had come to Britain to escape the Nazi regime. There had been a lack of small arms and light weapon expertise in the country prior to the war, and these immigrants helped to fill that gap. Korsak was one of those who chose to stay on in the UK after the end of the war and became head (CEAD or Chief Engineer & Superintendent of Armaments Design) of a design team based at Cheshunt in Hertfordshire. Janson would later succeed him in this role, and Janson’s rifle would come to the forefront of British small arms design.

As we might expect from a support weapon theoretically intended to replace the Bren gun, the Korsac features a relatively heavy barrel and a bipod, but unusually is in ‘bullpup’ configuration. Conceptually and mechanically the weapon is based upon the German FG-42 automatic rifle, an advanced development of the American Lewis gun designed for paratroopers and credited to Louis Stange of Rheinmetall-Borsig. The Fallschirmjägergewehr 42 was already quasi-bullpup in arrangement, albeit with a side-mounted magazine well. The FG-42 also provided the E.M.1 with its ‘piston extension’ (operating rod) and rotating bolt carrier group with two-lugged bolt at its head. As a result, it shares the FG-42’s closed bolt/open bolt operation modes for semi and automatic fire respectively. This includes the curious behaviour of the striker, which is cocked by the first ¾ inch or so of cocking handle travel before the bolt itself is unlocked and withdrawn by the remainder of travel. Inside, the striker slides rearward within the bolt, which stays in the closed and locked position. The protrusion on the bottom of the striker slides in a ventral slot on the bolt carrier, but in this mode, not far enough back to cam the bolt open and then pull it to the rear.

The sear is acting on the rearmost of two bents on a unique component known as the ‘slide’. This functions essentially as a forward extension of the bolt carrier. In the FG-42, the semiautomatic and automatic bents are machined into the underside of the bolt carrier group. In the Korsak E.M.1, the trigger mechanism sits further forward, and the slide compensates for that extra distance by acting as a forward extension to the bolt carrier group. This unique solution to the perennial problem of poor triggers in bullpup firearms obviates the need for a long trigger linkage bar or rod as in traditional bullpups, and is much simpler than the trigger mechanism of the Thorpe E.M.1. In the accompanying photos, the slide has been left inside the body, but its front portion is visible, protruding from under the gas block. This slide features two bents, which interface with twin parallel sears in the trigger mechanism housing (see below). These are manipulated by rotating the selector switch, which raises and lowers them in and out of engagement with the slide.

On Automatic, the right-hand sear is pushed up by the selector to engage with the front edge of the slide, holding the slide, bolt carrier, and striker to the rear (that is, fully behind the slide) to effect automatic fire. Set to ‘Rounds’ (or ‘Repetition’), the right-hand sear is dropped down out of engagement, and the left-hand sear is able to run within the machined track in the underside of the slide. It can now catch the front bent on the slide, holding only the slide and striker to the rear ready for semi-automatic fire.

When the rifle is assembled, the front edge of the slide acts as the automatic bent, placing the slide and attached bolt carrier almost fully to the rear (there is some over-travel to allow easy cocking) in open bolt condition. This assembly is then ready to be released by the right hand sear in the trigger mechanism (see below), after which it is pushed forward by the compressed recoil spring, closes, locks, and releases the striker for the first shot of automatic fire. In semi-automatic mode, the machined bent at the rear of the slide hangs up on the left hand sear. The bolt itself is fully in battery and locked, but the slide and striker are free to travel the short distance required to fire the first semi-automatic shot. This Weaponsman.com post on the FG-42 shows how this works in the context of the simpler direct engagement of the sear with the bents on the bolt carrier. The other significant point of divergence from the FG-42 is in the use of a tappet style short-stroke gas piston to set the working parts in motion. This is surprising given the other similarities with FG-42, and there is no surviving indication of the thought process here. Clearly, the Soviet lineage of self-loading rifles was thought to be superior in this regard.

The adjustable gas regulator features two settings for normal and adverse operation, and can be switched to the latter setting by depressing the detent with the nose of a cartridge and rotating clockwise (from the shooter’s point of view). Returning to the many gifts bestowed by the FG-42, we find a set of folding iron sights with a rotating cylinder for elevation adjustment of the rear aperture. Finally, in common with the FG-42 but also other British designs of the period, Korsak’s weapon was chambered for the full-power German 7.92 x 57 mm cartridge. The magazine associated with the gun appears to be a modified, rather than scratch-built, example from the Czech ZB-26, the British Bren magazine – itself derived from the ZB-26 – being too steeply curved for the cartridge. The lug/rocker catch system of the ZB/Bren family, also common to the FG-42, was also used. Finally, the (not quickly) detachable barrel with its simple cone-shaped flash suppressor is also derived from the ZB/Bren. The change lever (selector) operates as per FG-42 with its pull-to-engage, pivot to operate lever, but separates fire selection from safety catch. The former is marked ‘A’ and ‘R’ for ‘Automatic’ and ‘Repetition’* (see note at end – Ed.), the latter ‘F’ and ‘S’ for ‘Fire’ and ‘Safe’.

There is a hold-open device (HOD) behind the magazine catch, which is designed to hold the action open on an empty magazine, and then to automatically close the bolt when the empty magazine is detached. This is in contrast to later British designs, where the bolt remains held open until the magazine catch itself is operated to release the bolt. Interestingly, this does not function when manually operated, as the bolt carrier is not able to travel far enough to the rear to be retained. It is likely that this feature only worked when the weapon was actually fired, giving the bolt carrier sufficient velocity to compress the rubber buffer inside the butt-plate far enough for the bolt to engage the HOD. In addition, the magazine currently fitted to the gun in the National Firearms Centre collection, whilst it has been professionally modified to fit the gun, does not operate the HOD. Specifically, the standard ZB26 magazine follower features a groove that allows the nose of the HOD to slip into it and prevent the HOD from sticking up far enough to catch the front of the bolt. This suggests that, as Ian notes in the video above, the magazine may not be truly original to the gun as it was first constructed. In theory, the bolt could be manually held open by pressing upward on the tail of the hold open device, but this is fiddly to achieve in practice.

The Korsak pictured is one of only two surviving examples and the only one fully finished. As such it is not possible to test fire it, but fortunately some period information was recorded and other tentative conclusions can be drawn from the weapon itself. The cyclic rate was unsurprisingly quite slow at 450 – 500 rounds per minute, affording some chance of controlling the weapon if used in the assault rather than off the bipod. The recorded muzzle velocity is 2450 fps, which might seem low but is typical for 7.92 x 57 mm out of a barrel of the Korsac’s length (24”, similar to the Kar98K rifle). Effective range was given as 900 yards (823 m), which seems reasonable given the intended role.

The finished weapon is heavy for a rifle at 5.11 kg (11.51 lbs), but reasonable for an LMG of the period. The compact design was forward-thinking and, despite present-day objections to bullpup designs, the official test report (see Dugelby, p.19-21) praises its ‘ease of balance and manipulation’. However, it was noted that the design ‘…was for right-handed shooters only’, a departure from the Bren; unlike their rifle-armed colleagues, left-handed Bren gunners were permitted to operate the weapon naturally. By contrast with the Janson E.M.2, the cocking handle is on the left side where the majority of shooters can best operate it with the support hand. There is little hint of wartime austerity in the manufacturing methods used, with receivers of machined steel and the handguard and pistol grip of carved wood. The example illustrated is finished to a high standard.

The bullpup arrangement shaved another few inches off the overall length of the FG-42, but in the process the helpful buffered stock of that design was lost, replaced by a thick hard rubber buffer block at the rear of the return spring (located in the buttplate assembly). As well as this red rubber block in line with the operating rod, there is a second buffer block located in the butt-plate directly behind the tail of the bolt carrier. This seems likely to have negatively impacted felt recoil and controllability. There are other ergonomic negatives to consider. The pistol grip is chunky and excessively vertical in grip angle. The bipod legs are fiddly to deploy, with rather weak sprung catches that need to be manually depressed to lock the legs into the deployed position. The outer sleeve over the rear sight cylinder makes it far harder to grasp and rotate than the FG-42 original. None of these points appear in the short official assessment, but a couple of mechanical flaws were identified. The report notes that ‘…the striking energy on single shot is insufficient due to friction of the slide in the body’. Indeed, the weakness of the striker spring is evident in the NFC example. The short-stroke piston was also found to deform in operation, and it was recommended that it be enlarged and fashioned from ‘high yield point’, rather than case-hardened, steel. Both of these would seem to have been easy fixes if development had continued.

Work on the Korsac E.M.1 ceased in May 1947, but much of the design carried forward into a new bullpup assault rifle designed to fire a new ‘ideal’ calibre cartridge. This emerged later that same year, and would become known as the Janson E.M.2. Confusingly, the Thorpe E.M.1 bullpup rifle was not designed until the following year. This was proposed not as an LMG but as an alternative to the E.M.2, and consequently was a very different weapon despite superficial similarities. In fact, the Korsak E.M.1 and Janson E.M.2 have much more in common, the latter being essentially a rifle derivative of the former.

A Note on Nomenclature

This weapon’s designation is commonly rendered ‘EM-1’, and this is what will be found in the vast majority of the secondary literature. ‘EM1’ is also occasionally encountered. However, the manuals use ‘E. M. I’ and ‘E. M. 2’ for this series of weapons. We have standardised on ‘E.M.1’, with an Arabic numeral and the spaces removed.

*In the Second World War period it appears that ‘R’ officially stood for ‘Rounds’. This potentially confusing term was replaced by the more specific ‘Repetition’ some time during the development of the Enfield Weapon System.

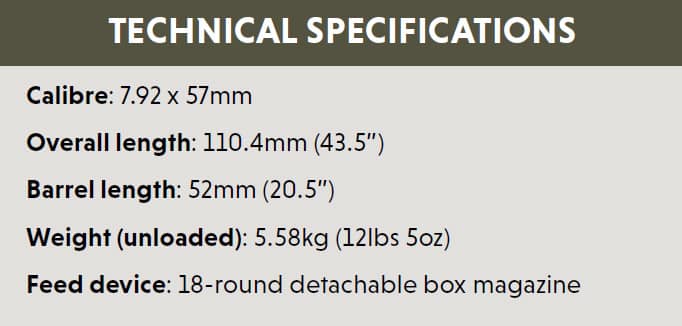

Technical Specifications

Calibre: 7.92 x 57 mm

Overall length: 110.4 mm (43.5”)

Barrel length: 52 mm (20.5”)

Weight (unloaded): 5.58 kg (12 lbs 5 oz)

Feed device: 18-round detachable box magazine

Special thanks to the National Firearms Centre at the Royal Armouries, who graciously allowed ARES access to their world-class collection for research and photography.

This is Part 1 in a series of posts examining the developmental history of the United Kingdom’s E.M.1 and E.M.2 designated firearms. In the next issue of SAR…

See www.armamentresearch.com for further original content.