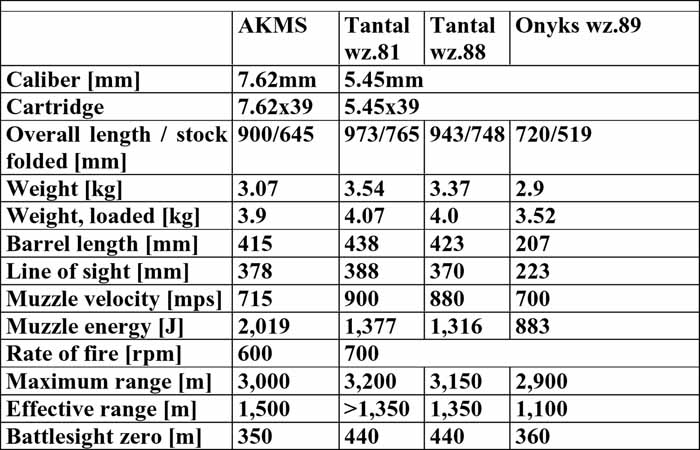

American experience of the 5.56mm assault rifle use during the Vietnam War, despite all the setbacks of the early M16 and M193 Ball, did arouse curiosity and then desire to introduce a similar weapon on the other side of the Iron Curtain. In the mid-1970s the Soviets had finally introduced another generation of the Kalashnikov rifle and LMG called the AK-74/RPK-74.

The basic weapon of the new family was the AK-74 rifle – a thoroughly modified AKM chambered for the new 5.45x39mm caliber. The interchangeability between the AK-74 and AKM, despite the nearly identical appearance, is a mere 50% – and limited to non-essential internal parts like pins, retainers, screws, springs, etc. Although the barrel length of 415 mm was retained, the barrel itself was entirely new, designed from scratch and non-interchangeable with the older model. So were the gas chamber (initially fitted with oblique gas channel, then changed to a perpendicular one) and front sight post with muzzle thread moved from the actual muzzle to the front sight base body that the barrel just poked through. Onto this increased diameter muzzle thread a completely new, complex, multi-functional muzzle device was screwed on, exchangeable for the blank-firing attachment.

The muzzle device was the most identifiable feature of the new rifle. It was a combined flash-hider, muzzle brake (single-baffle type side openings), and muzzle jump compensator, all rolled in one, with additional asymmetric holes drilled in an initial expansion chamber, helping to stabilize the rifle in bursts. The receiver was also redesigned, with most changes concentrating within stock attachment, extractor and magazine well areas. The bolt carrier was lightened, as was the bolt, and plastic magazines were introduced enabling stripper clip loading. For the first time a compact model of the Kalashnikov rifle was fully introduced in 1979. The AKS-74U (in America also known as the “Krinkov” – for some obscure reason) took over most of the functions hitherto reserved for a submachine gun. The shorty carbine had a 206 mm long barrel with front sight post placed directly on top of the gas chamber. Here also the muzzle device was being screwed onto the thread placed at the mouth of the gas chamber body/front sight base. This one is also a multi-functional device, consisting of the cylindrical initial expansion chamber culminating in a cone-shaped flash hider. The new rear sight, a flip-over affair, was riveted to the top of the receiver cover, which was hinged, machine gun style – rather than separate like in all other AKs, including the AK-74.

Tantalean Ordeal, Prelude:

Poland’s Bumpy Road to Small Arms Independence

Shortly after that, Poland with all other Warsaw Pact countries started to prepare for the introduction of the new standard – a small-caliber individual weapon system. When Polish authorities inquired about the possibility to obtain the license rights for manufacturing of the AK-74, the price tag and export limitations were found outrageous enough to warrant a decision to circumvent the Soviets – and do it “my way”, as Frank Sinatra put it. And so the decision was made: the Polish soldier of the future would wield a similar – but not the same – weapon. In order to achieve that goal, Polish designers undertook an ambitious task: to build a rifle at the same time identical to AK-74 – and completely different.

Fortunately, they did not have to start entirely from scratch. As early as 1973 the Warsaw’s Military Technological University (WAT) design team created a new intermediate round of improved ballistics, the 7x41mm, code-named “Marszyt”. The bullet had a trajectory peaking only 240 mm high at 300 m, leaving the muzzle at 770 mps (2,530 fps), which given a 7.68 g (118-grs) mild steel-cored ball weight would give the muzzle energy in the 2,200 Joule region. As of 1976, the Osrodek Badawczo-Rozwojowy (OBR, or R&D Center) of the Radom’s “Works 11” (known to all civilians as the ZM Lucznik Mechanical Works, the country’s prime manufacturer of typewriters and sewing machines) undertook an ambitious task of creating a modular firearms system chambered for it, code-named “Lantan”. The modular weapon system was supposed to be based upon a common receiver, which by fitting different barrels, magazine-feed modules, belt-feed modules and/or stocks, would become a paratrooper carbine, an assault rifle, a designated marksman rifle, a light machine gun, a tank machine gun and a SAW-style machine gun (the two latter being belt-fed), just like it was the case with the Czech URZ or US Stoner 63 systems. Of course it was doomed from the start, for two reasons. One was obvious: objective in nature and common to all modular weapon systems of the 1960s and 70s, a short-barreled carbine with a sturdy machine gun receiver wasn’t the most successful combination, both weight and economy wise. The deciding factor was however, that the Soviets staunchly opposed the introduction of the 7mm round, even though it proved to be a nail-driver with excellent penetration capabilities.

Only two prototype rifles were ever manufactured, with a mere dozen thousand rounds of ammunition, mostly used up for testing. After Moscow said “Nyet” to the Lantan project, two regular AKMSs were converted to 5.6mm caliber, firing the early version of the Soviet small-caliber intermediate ammunition, the 5.6x39mm Running Deer “sporting” round. The 5.45x39mm was then still a secret, jealously guarded from friend or foe alike. Testing the 5.6mm AKMS of course lead nowhere – just like the Soviet testing of the AKM chambered for the same round ten years earlier, which led to creation of the 5.45mm round.

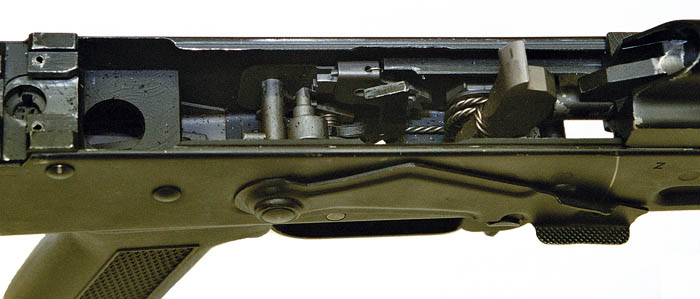

Then, in the late 1970s, after the Lantan project was forcedly abandoned, the Poles took another bid at improving the basic AKM “their way” and designed the AKMS wz.80 (M1980) with a three-round burst limiter. This three-round burst capability was one of the three ways tested then to improve the full-auto accuracy and hit-probability of the AKM. Two others were introducing a muzzle device similar to the one used in the AK-74, and reducing the rate of fire, following the Japanese way (as in the Type 64 rifle). Polish designers took apart and studied three-round burst mechanisms of the French FAMAS, Belgian FN CAL and Swiss SIG 540, and choose the simple and sturdy Belgian ratchet as a pattern. The modernized AKMS rifle fitted with a three-round burst mechanism was designated AKMS wz.80 – but never introduced into the inventory of the Polish Army. It differed from the original AKMS by having fire-selectors entirely separate from the safety function; even though combining them into one large side lever on the right side of the receiver was a salient feature of the original Kalashnikov design. The Polish AKMS wz.80 was different in having a separate safety lever on the right side, looking just like the original safety/selector, but now with just two positions left – upper, safe (“Z” or Zabezpieczony) and lower fire (“O”, like Odbezpieczony), instead of the original three (usually unmarked “Z”, “C” – for Ciagly or fully-automatic and “P” – for Pojedynczy, or semiautomatic). The fire-selector function was moved to a separate lever on the left side of the receiver, with three positions: “C”, “S” (for Seria, or burst) and “P”, in counter clockwise order. The trigger lacked the typical AKM hammer delay, and the semi-auto sear had a pin protruding out of it to cooperate with the burst limiter toothed arc. On the left inner side of the receiver a burst-firing mechanism pack was added. The actions of putting the rifle on safety, off safety, and shooting semiautomatically were identical to the old milled receiver AK-47 without a hammer delay. If the fire-selector was set to “S”, the semi-auto sear was held back by the two-toothed arc, set in motion by the hammer movements. After the third shot was fired, the ratchet no longer held the semi-auto sear, which is then freed to snap into place and catch the hammer. The firing ceases exactly like in semiautomatic fire. Upon releasing the trigger, the mechanism resets itself and the toothed arc snaps up against the semi-auto sear’s protruding pin, ready for another three-round burst. Unlike the American three round mechanism of the M16A2/M4, if the firing ceases after just a shot or two, the next burst would always be full three rounds long. Moving the fire selector lever to the left side of the receiver necessitated a slight undercut in the left folding stock strut to clear the lever while folding underneath the receiver.

Thus the stage was set: after two Warsaw Pact armies (East Germany and Bulgaria) were forced to purchase the pricey AK-74 licenses, Poland took the bumpy road, deciding to design their own cartridge (codenamed project “Cez”) and the new rifle – an indigenous circumvention of the AK-74, codenamed project “Tantal”.

Tantalean Ordeal, Act One:

Turning AKM into AK-74 “My Way”

The initial studies on the 5.45mm Polish rifle were undertaken at the Radom factory’s OBR R&D Center as early as spring of 1980. The AK-74 was an obvious choice for a pattern, but Polish designers wanted their rifle to retain a much higher degree of interchangeability with the AKM and use the freshly designed three round burst limiter of the AKMS wz.80. The receiver of the AKM (in America frequently mislabeled as a “stamped receiver AK-47”) was modernized only in the necessary degree, with ejector lengthened enough as to reach the much narrower bottom of the case. Another change was the new sight base, necessitated by the re-designed gas tube and upper handguard, eliminating the hitherto used gas tube latch on the battle sight base. The new gas tube latch was fitted to the opposite end of the gas tube, on the handguard ring. The new gas chamber had a perpendicular gas opening and a front sleeve around the barrel where the bipod was attached. The moving parts consisted of the lightened AKM bolt carrier and a modified bolt, with smaller diameter bolt face and open-sided extractor cutout (patterned after the AK-74). The brass hats envisioned fitting each of the new rifles with a rifle grenade capability with new generation bullet-trap rifle grenades. At the same time, the new rifle was to be fitted with a folding stock only – and that meant that the traditional bottom-swinging folding stock of the Kalashnikov rifles had to go. The sheet-metal stamped and riveted struts of the AKMS stock would never be able to withstand the level of recoil connected with rifle grenade firing. In the late 1950s experiments with AKS-47 fitted for rifle grenade firing proved that even the older pattern solid bar stock struts were giving way. So the new rifle had to be fitted with a new, more durable pattern of the central-strutted stock. The East German MPiKMS-72 was chosen as a pattern, with its simple loop-stock, called a “Pogrzebacz” (Ash-Poker) by the Polish soldiers.

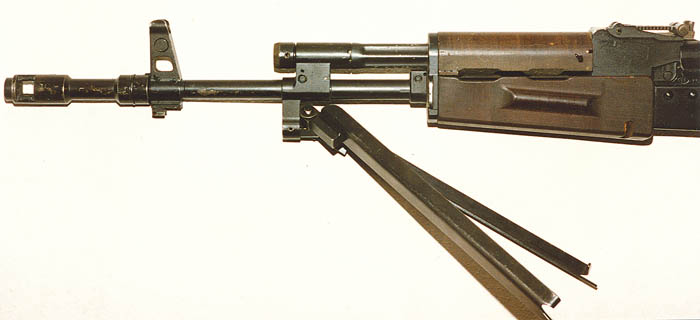

The Tantal stock hinge is fitted to the receiver by lieu of the upper screw and the pistol grip screw, going through the flat spring of the stock latch. The entire folding stock hinge can be replaced with an AKM wooden stock, if need be. The only wooden stocked Tantals ever to be assembled, however, were those illustrated in a manual and weapon training wall chart. Tantal was never manufactured nor used in such configuration. The flat latch spring at the same time acts like a hinge brace and is a significant detour from the GDR model (with separate wire spring), making the Polish design a more original one. The handguard and gas tube retaining ring, as well as the upper handguard and gas tube itself were a significant departure from both AKM and AK-74. The retaining ring latch is a crossbolt with a cutout, rotating in a perpendicular groove on top of the barrel. Each time the gas tube is to be removed for cleaning, the latch bolt has to be rotated so that the cutout clears the barrel and lets the ring be slid forward, freeing both handguards. The “kbk wz.81” (M1981 Carbine – in Polish military parlance all intermediate round chambered rifles regardless of caliber and barrel length are “carbines”) earliest variant of the Tantal had a screw-driver slot in the latch bolt. This defied the common sense approach of making field-stripping as easy as possible without the use of tools, in order not to distract the soldier, who has many more immediate problems in the field, from cleaning his rifle. Later on the screw slot was replaced by a lever extension. Unlike the AK, the Tantal upper handguard is not fixed to the gas tube. The gas tube is a separate part, wedged between the gas chamber flange and rear sight base, then topped with a plastic upper handguard doubling as a gas tube retainer, which in turn is held by the handguard retainer ring. This unusual feature’s sole reason was to enable the lower handguard dismounting without field-stripping the rifle. This was in turn required by the underbarrel wz.74 Pallad 40mm grenade launcher, mounted on the special mounting jig, replacing the regular handguard. This has to be seen as bizarre at least, unnecessarily complicating the weapon in order to mount an accessory issued at a one-per-squad basis, and never mounted or dismounted in the field.

In late 1981, with mounting political and social unrest in Poland in the last phase of the Martial Law preparation, the Tantal development program was suspended. On Sunday, December 13, 1981, in the early morning hours the military took to the streets, as the Polish Communist Party crushed the Solidarity movement, putting an end to the 16 months of the “Freedom Carnival” triggered by the Gdansk Shipyard strike, and Lech Walesa’s meteoric rise to fame and power. For a year and a half, until July 22, 1983, the country ground to a halt, with curfew, cut – then tapped – telephones and military patrols in the streets, punctuated by epic Solidarity demonstrations, ruthlessly suppressed with water-cannons, rubber batons and tear gas by the infamous ZOMO riot police.

Radom’s Works 11, itself a hotbed of Solidarity and the scene of the 1976 workers’ riot that led to the creation of the organized political opposition in Poland, was certainly not a secure place to develop a new weapons system. Nevertheless, the 5.45mm program continued on, and Skarzysko-Kamienna’s Works 21 ammunition plant (a.k.a. ZM Mesko, lawn-mower and coffee-grinder manufacturer) finally mastered the tricks of the 5.45x39mm ammunition manufacture in 1983. After the first experimental batch was tested positively, the ammunition source was at last secured, eliminating the need to buy it from Soviet Union. In 1984, the Ministry of National Defense’s Office of the Chief of Military Technology Research and Development issued an order for “developing of the 5.45mm automatic rifle”, for which in 1985 the Technical and Tactical Requirement document was issued. The new rifle was to be of “comparable measurements” with the AKMS, and not heavier than 3.3 kg (7.3 lbs). It was to fit into the existing firing ports of the armored vehicles (e.g. the BMP-1 infantry fighting vehicles, or the 2S1 Gozdzik self-propelled amphibious 122mm gun-howitzer) as well as standard AKMS rifle racks installed in military vehicles.

The Acceptance Requirements did not deviate much from the standard AKM procedures. A minimum service life of 10,000 shots was required, including 150 shots with dummy 300- and 500-gram rifle grenades. The reliability target was set at 0.2% jams (or 20 malfunctions in entire service life of 10,000 shots). The required accuracy was an extreme spread of a 5-round group, shot from a rest, prone, semiautomatically, at 100 meters to fit within 150 mm (5.9 inches).

The initial batch of the wz.81 Tantals was sent out for testing in 1986 and failed terribly, missing its chance to be introduced into the inventory of the Polish Army. The original test minutes are still confidential, so one cannot state what went wrong. Some things were obvious then: the length of the rifle with stock folded was too long for standard AKMS racks, which would necessitate rebuilding all existing racks built into each and every military truck, car, or armored fighting vehicle – thus the next model was shortened. The magazine was another problem. The one used with Tantal wz.81 had a top part taken directly from AKM, which enabled to attach a wrong magazine loaded with 7.62x39mm rounds to the rifle – while the Soviet AK-74 magazine could not, which prevented interoperability in the future liberation of the Western Europe.

Tantalean Ordeal, Act Two:

The Great Rifle Grenade Folly

The Polish Army was the first, and despite occasional experiments in other Soviet Bloc countries, the only Warsaw Pact military to design, manufacture and field rifle grenades in any quantity. Polish rifle grenades were fired with a special grenade blank UNM wz.43/60 from a 20 mm outside diameter grenade spigot screwed onto the muzzle thread of the specially modified wood-stocked milled receiver AK-47, called the “karabinek-granatnik wzór 1960 (kbkg wz.60), or carbine-grenade launcher M1960, with a specialized variant with detachable wood stock, the kbkg wz.60/72 for airborne troops (only 500 ever made). During the 1970s, taking the cue from the US Army, the kbkg wz.74 AKM rifle with Pallad 40mm underbarrel grenade launcher chambered for the 40x47SRmm fixed rounds, was designed to replace the rifle grenades. The rifle grenades were criticized by the military as awkward to handle, kicking like a mule, and dangerous in the event of failure to clear the weapon properly before ammunition change (from live to grenade blanks) prior to firing of the grenade. With a failure to clear the rifle, a live ball could be left in the chamber and grenade would detonate on launching if struck by the bullet. Several such incidents occurred, both in training with the Polish Army, and in combat, when Polish rifle grenades were fielded by the North Vietnamese Army and the Palestinian Liberation Organization. All militaries of the world were transferring from the spigot-fired rifle grenades to the 40mm (or so) barreled grenade launchers for anti-personnel work and shoulder-fired RPGs for anti-tank defense, as the AT rifle grenades were long ago insufficient against thick-skinned opposition. Tactical-grade commanders all knew that, and reported it to their superiors, but the higher brass of course knew better and insisted on having a new generation of the rifle grenades, with bullet trap, fired with a live ball round. A whole new design program was started, codenamed “Fosforyt”, to create these. As the energy of the small-caliber intermediate round was no match for the specialized grenade blank loaded with as much as 2.5 gram of the fast-burning P-125 powder (as opposed to 1.67 gram of the VUFL powder for a 7.62x39mm ball round), the new grenade had to have increased inner diameter, to give the gases more area to push against when firing. The tailboom of the new grenade was thus of the 30 mm inner diameter (as opposed to 20 mm in kbkg wz.60). This in turn necessitated a 30 mm sleeve on the 22 mm thick multirole muzzle device. This sleeve was deemed an integral part of the rifle – to the extent of turning down its muzzle end to accommodate the 6H4 AKM bayonet cross-piece ring. The early sleeved muzzle device can be identified by having three perpendicular grooves on the outside surface, as opposed to the later model one with much wider groove.

Tantalean Ordeal, Act Three:

Too Little, Too Late

The improved and partly redesigned (AK-74-compatible bolt carrier, bolt and magazines, shortened to match the AKMS overall length) prototype Tantal was factory tested by the end of 1987. A prototype batch of two was sent back for military testing, which took place between March and June, 1988. Both rifles had still utilized Soviet magazines (early orange plastic ones) and had wooden forends. Tantals were tested against the AKMS and Soviet AK-74, firing the Polish-manufactured PS ball ammunition and Soviet 7N6 tracer. 15,000 rounds were pumped through the first prototype, and in excess of 20,000 through the other, proving that just like the AKMS, the new rifles had much more service life in them, than the 10,000 shots required and expected. The dummy 350 g rifle grenade was clocked at 53 mps, giving it a 210 m range, a little short of the expected 250 meters. The heavier 500 g grenade achieved respectively 46 mps velocity and 180 m effective range. During the test some drawbacks were noted, especially while firing rifle grenades, e.g. increasing play of the barrel mounting block inside the receiver, falling out of the receiver cover and excessive, increasing play of the folding stock hinge. Modifications were ordered to remedy these, and the 30 mm sleeve was ordered to be removed from the muzzle device and incorporated inside the grenade’s tailboom.

The improved rifles were again tested early in 1989 and finally found fully compliant with the requirements, so the initial batch for troop testing was ordered and in 1990 actually handed over to the Army for troop testing. In 1991, the 5.45mm rifle came into series production and was introduced into the inventory of the Polish Army as the “5.45mm karabinek wz.1988 (kbk wz.88)”, officially dropping the R&D-phase codename of Tantal – even though it persevered as the popular name of the firearm.

It was however all too little and too late, as the November 1989 Fall of the Nations, set into motion by Poland’s June 1989 power changeover, swept Communist rule from Central Europe. In Poland, Solidarity resumed semi-legal activity in 1988, then it was re-registered and subsequent Roundtable talks with the Communists led to a peaceful change, following the June 1989 landslide victory of the Solidarity movement in the country’s first post-WW2 free election. Just as the Tantal was ready for series production, it suddenly became redundant almost overnight after Poland opted for full integration with the West and future membership in the Northern Atlantic Treaty. With plans like these, a brand-new rifle firing Warsaw Pact ammunition was useless and Tantal was dropped in 1994 after just a couple dozen thousand were manufactured.

Even over this short span of the production period, numerous design changes were introduced. The trigger mechanism was modernized, replacing the AK-style one-piece hammer-and-trigger spring with separate trigger and hammer springs. It gave one part more to detach during detailed stripping, but putting it back together was thus simplified. Now the hammer spring could be set on the hammer, short loose ends rested against the bottom of the receiver, and after the hammer pin was reintroduced, the hammer group was ready to work. This reduced the time and effort needed to put the rifle back from a detailed strip without the need to ply the long loose ends around the trigger mechanism’s pins and bits. (Only Soviet and Polish operator’s manuals trusted soldiers with a detailed stripping procedure of the rifle. All other Warsaw Pact OMs only dealt with field-stripping for cleaning; reserving detailed stripping for the authorized repair personnel only). Other changes included fitting a lever extension, instead of the screwdriver slot to the forend ring retaining cross-bolt, thus eliminating the need of tools for stripping. The finger extension was carried over from the late series Tantal into the 5.56mm successor, the Beryl. Another change was of mostly of cosmetic value: orange and tan (generally, but ranging from yellowish to deep brown) furniture were later on unified to flat black plastic, giving the rifle a much more uniform and serious look. The new-style black lower handguard was AK-74M-style ribbed to improve grip. Similar black plastic furniture was also developed for the Onyks shortie.

At the same time the long-time magazine furnisher to the Radom Works 11, company from Lódz called Wifama, had gone bankrupt and the Radom factory had to introduce their own plastic magazines instead of the hitherto sheet-metal ones, used for AK, AKM and Tantal. Bodies and followers were molded out of the black fiberglass reinforced polyamide, which reduced their weight and price significantly, at the same time improving their reliability and mechanical resistance. The Tantal design is protected by the Polish patent PL 160959 of 1993, issued to Krzysztof Styczynski, Bohdan Szpaderski and Boguslaw Bialczak.

The 5.45mm wz.88 rifle is an automatic, gas-operated weapon with long-stroke piston. The bolt turns to the right for locking. An automatic sear prevents a discharge before the bolt is fully locked. Ammunition is fed from a 30-round staggered column, double-position curved box magazine, initially of full-steel design, then with plastic body and follower. Open, mechanical sights comprise a tangent rear sight with U-shaped notch for firing at distances from 100 to 1,000 meters at 100 m increments with a fixed battle-sight position “S”, enabling a torso shot up to 440 meters. The front post sight is of the typical AK design, set on top of the high carrier, inside the slider for windage setting and can be screwed in and out for elevation. Tritium night sights are standard on all rifles. (It is interesting to note that it was Poland that pioneered radioactive tritium lit sights on the eastern side of the Iron Curtain: all other Warsaw Pact countries from USSR down used just phosphorous paint for night shooting.) The rifle has a right side folding monostrut stock, enabling firing and reloading of the weapon with the stock folded.

There were two weapons developed from the wz.88 Tantal: the wz.89 Onyks carbine, and the 5.45mm kbkg wz.74, or Tantal with Pallad 40mm grenade launcher. A limited series of the very early series-produced Tantals were fitted with a mounting rail on the left side of the receiver, meant for the NSP-3 and then for the indigenous Polish improved NV sight, the PCS-5 Gabro from Warsaw’s PCO company. Fitting these rails impaired the function of the fire-selector lever, which extended only 2-3 mm past the edge of the deployed NSP-3. It was also planned to use this version as a DMR (designated marksman rifle) by fitting a GDR manufactured ZFK 4×24 optical sight, utilized with the similar night variant of the East German license-manufactured rifle, the MPi-AKS-74N. Nothing transpired out of it, as the GDR was re-unified with West Germany before any quantities of the sights were ordered. Even with all the changes made to barrel, muzzle device, stock, bolt carrier and bolt, return spring assembly, trigger mechanism, magazine, gas tube and forend, the wz.88 Tantal is still more an AKM, than the AK-74.

The 425 mm long barrel is cold-forged, hard-chromed, with 4 RH grooves of 200 mm pitch. The multi-functional muzzle device has an external diameter of 22 mm to exclude fitting an old style rifle grenade without bullet trap. The initial expansion chamber of the device has got three openings drilled through, 120 degree one of the other. The Polish muzzle device is much longer than the Soviet as it also doubles as the rifle grenade spigot. The initial wz.81 Tantal had an integral bipod, but after it was nearly broken off by the recoil of the rifle grenades firing, a new detachable bipod was fitted, patterned after the M16 “washing clip”. This is being fitted to a special sleeve incorporated into the gas chamber body, with cleaning rod (carried in the usual AK way under the barrel) inserted into a special opening of the bipod serving as a tilt stop.

The single-strutted stock is folds to the right, along the right side of the receiver. The stock strut has its rear end hammered flat, then folded into a triangular buttstock, with a rubber block inside the upper corner to avoid scratching the receiver side. The stock hinge latch, enabling folding of the stock, is placed on the left side of the stock hinge assembly and doubles as the stock retainer in both positions. One has to depress the stock latch with one hand and only then fold or open the stock strut with the other. To avoid loosening of the receiver cover, common during the rifle grenade firing, a manual latch was added to the return spring guide, borrowed from the kbkg wz.60, enabling to lock the cover after the rifle was put back from a strip.

Tantalean Ordeal, Interlude:

A 5.45mm Onyks wz.89 Carbine

After the wz.88 Tantal rifle was ready in late 1987, the OBR team started designing a compact version, a Polish clone of the AKS-74U. In late 1990, the first prototype was ready for testing, which took place in early 1991. The tiny carbine passed the tests with flying colors, but then a decision was made to fully unify the receiver with the rifle, which necessitated a thorough redesign, as the first prototypes had a Krinkov-style hinged receiver cover. The redesign took a while, and it only reached series production in 1992 – to be discontinued after just 200 were made. Officially it was rejected by the Army because the flash-hider was not efficient enough, but it was the politics that really polished it off, along with the older brother. Earlier on, two prototypes of the 7.62mm carbines based upon AKMS met with the similar fate.

The “5.45mm subkarabinek wzór 1989 (subkbk wz.89)” is basically a chopped-down Tantal. The chop-job improved the handling abilities at the expense of the shorter barrel, bayonet and bipod. Strangely enough, the carbine retained the rifle grenade capability though being the world’s one and only rifle-grenade capable shortie. The Onyks has much more parts common with the standard rifle than the AKS-74U. The barrel length was reduced to 207 mm, also the gas tube and both handguards were chopped – but the latter are still retained with the same retainer ring fitted with the old style slotted crossbolt, even though the Tantal was already upgraded to a finger lever. The Onyks gas chamber is a copy of AKS-74U’s one, with muzzle thread at the cylindrical portion of the front sight base body. A muzzle device doubling as a grenade spigot or BFA can be screwed onto that thread. The sight base of the Onyks is of an original design. The first prototypes had an AKS-74U ear-protected flip-over sight and a likewise hinged receiver cover. A decision was made, however, to unify the receiver and discontinue the hinged cover, replacing it with the ordinary detachable one, like on the full-length Tantal. To retain the proper sight radius, a cantilever sight rail was riveted on top of the barrel attachment block reaching back over the receiver cover. On the side of that rail, a mounting bracket for the laser sight was added. In 1990 tests, that arrangement was found insufficient and thus it was again redesigned. The new sight cantilever is almost double the length of the original, and an attaching rail for the PCO-made CWL-1 red dot sight was added to the top of the cantilever. The Onyks’ rear sight is a flip over with two U-notches (100-200 and 400 m) and the front sight is an AK-style windage-adjustable screw-in screw-out post. Some carbines were fitted with tritium night sights.

Tantalean Ordeal, Epilogue:

5.56mm Tantal and Onyks

Radom’s ZM Lucznik wasn’t waiting for the Warsaw Pact to tumble down with hands neatly folded. Even as the Tantal and Onyks were coming into series production, it was obvious that a 5.56mm version would be needed – if not for the Army, then for export now that the USSR did not hold an iron fist upon each export contract. As early as 1990 both Tantal and Onyks were redesigned for the 5.56x45mm round, and designated respectively “5.56mm kbk wz.90” and “5.56mm subkbk wz.91”. These were almost indistinguishable from the original ones, if not for the uniformly black furniture: these were in fact the first all-black Radom rifles, setting the new trend for all other products. Changing of the ammunition increased the muzzle velocity and energy just slightly, from 880 to 900 mps and from 1,316 to 1,620 Joules for the rifle and respectively from 700 to 710 mps and from 857 to 1,010 Joules for the carbine. Despite the early success, the 5.56mm weapons were soon discontinued – only to be re-started a few years later from scratch as a project codenamed “Beryl”, leading to adoption of the 5.56mm kbs wz.96 Beryl – but that’s another story.

Summing up

The Tantal was by far the most original of all 5.45mm Kalashnikov clones ever manufactured. It was the only one with rifle grenade capability and the only one fitted with burst limiter. Were any of these really needed and useful? That’s still open to debate, but it had them both, nevertheless. It is without doubt that projects connected with small-caliber rifle and cartridge (Tantal, Onyks and Cez) gave the Polish defense industry priceless experience and self-reliance, which proved invaluable after the Warsaw Pact fell down, and a head start which enabled a fast changeover to the 5.56mm NATO round – several years before Poland was accepted into the Alliance. However, there were several wasted chances mostly in the ergonomics department and sighting systems. Redesigning the AKM into a small-caliber rifle was the best chance to get rid of the complicated and expensive tangent sight in favor of a peep. Most of the many sighting distances marked on the tangent sight leaf are simply abundant. Who would ever pick a target vulnerable to the .223 bullet at 1,100 yards, much less be able to aim at it with U-notch and pin-sized front post sights? With modern flat trajectory rounds the battlesight zero setting “S” (“Staly” or permanent) enables the shooter to engage a torso target at distances up to 440 m (5.45mm) or 460 m (5.56mm), which in modern combat is perfectly enough for individual fire. What are all the other distances marked for? God only knows, really, and since painting rifles in camo patterns became a fashion also in the Polish Army, one can see with a naked eye that most sliders on these leaves were never moved – the paint on the leaf edges was never cracked. Besides, in these days iron sights are mostly of BUIS (or backup for the optoelectronic sight) value anyway.

Nowadays Tantals are history in the Polish Army. After the ammunition stocks were used up the rifles were withdrawn from the units and stored; replaced with either AKMS or Beryls. The last unit to utilize these was the Polish contingent of the UNIFIL, United Nations peacekeeping force in Lebanon, where these were basic individual weapons as late as 2004.

As of the 1970s, Polish small arms projects are assigned names of chemical elements, mostly metals – Wanad (vanadium), Cez (cesium), Beryl (beryllium) for codenames. Unfortunately, the anonymous civil servant, whose eye scanning the Mendeleyev Periodic Table for a fitting codename caught the name of the Group 5, Period 6, Block d metal “tantalum” with the standard atomic weight of 180.9, proved to be a prophet. The history of the Polish first small-caliber rifle reflects the ordeals to which Tantalus, mythical king of Lydia, was condemned by Zeus for feeding his son’s meat to the gods. For his crimes he was to suffer the unceasing dread of being crushed by a huge rock which hung suspended above his head; he standing up to the throat in water, possessed of a terrible thirst that he could never quench, and a gnawing hunger that he tried to assuage with the tempting fruits that hung above his head, but withdrew as soon as he reached for them. Likewise, the designers of the Tantal were ever so close, yet their success was denied to them. It took them just a year to build the rifle – but then each time they thought the goal is within reach, something happened to push their target further still. And when they finally caught up with it and perfected it – then no one needed it anymore.

Perhaps the final lines of Paul Anka’s famous song sung by Frank Sinatra would sum it up nicely: “For what is a man, what has he got? If not himself, then he has naught. The record shows I took the blows, and did it my way!”

| This article first appeared in Small Arms Review V12N12 (September 2009) |