By Dan Shea

In that ever spiraling event that is called an “Arms Race”, every leap forward is an answer to the opponent’s move. As one man added armor, the other added a crossbow. When explosives became more stable and reliable, firearms and their projectiles were developed. Through the wars of the Nineteenth Century, the progression sped onward. By the First World War, that “War to End All Wars”, the firearm in its near perfect form-the Machine Gun-had brought the battlefield to a standstill. Sir Hiram Maxim’s gun, the so called “Devil’s Paintbrush”, was on both sides of the conflict in Europe, and all Hell had broken loose in the muddy, bloody trenches. Companies died over yards of ground, and the trench lines were fought over by grim men who had little hope of victory on the horizon.

Enter the tank.

The first small tanks were sent out onto the battlefields with two men and a machine gun. They had enough armor to stop rifle caliber rounds, and if the terrain favored them, they could break through the enemy’s lines and breach them enough for the infantry to follow. The stalemate had been broken. The British were the first to introduce the new tactic in the Battle of the Somme in 1916, followed quickly by the French and the Germans. The machine gun carrying tanks were somewhat effective in their role, effective enough that the men facing them had to come up with a way to combat them. Grenades existed at that time, but that required getting very close. Artillery generally couldn’t keep up with the new, mobile target, and wasn’t readily available in many areas. Upscaling a rifle seemed to be in order, and the Germans did it first with the M1918 Mauser, a 13mm round with a penetrating projectile. Essentially, this was a massive bolt action rifle. Simply shoot the tank where you think it would stop it mechanically, or kill the operator.

The war ended in 1918, but not before stimulating the minds of the military communities in most countries. Over the next few years, many larger caliber “anti-tank” rounds were tried, and numerous rifles were invented. When country “A” would make a .55 round, country “B” would thicken their armor to defeat it, and make a more powerful engine to drag that armor around. Country “C”, looking on, would go to 14.5mm, and country “D” would armor a tank to defend against that threat. Eventually, in the years preceding the Second World War, the rifles had achieved assorted 20mm cartridges, massive projectiles, tremendous recoil, a lot of weight, and they were quickly made obsolete by advances in armor and engines that made them useless on the battlefield. The Lahtis, Solothurns, Boys, PTRSs, etc were relegated to the armory back room very quickly.

Enter the shaped charge.

The major obstacle facing the anti-tank rifle designers was simply having a projectile with enough speed and mass to defeat the newer armor. The rifles were getting too large and cumbersome to be effectively carried; they were verging on being small artillery pieces needing wheels and carriage. Some, in fact did have wheels and carriage. The idea had been to arm infantry soldiers with a man portable device with which they could aggressively maneuver and engage a tank. Now, those soldiers were being bogged down by the size of the weapon.

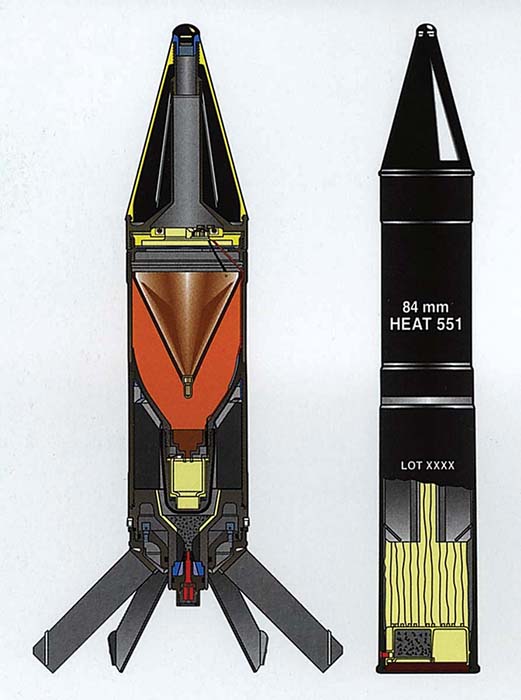

SAR has gone over shaped charges in the past. Essentially, the explosive in a projectile is formed with a hollow center, shaped around a metal or other suitable material hollow cone. The explosion is triggered from a forward fuze, separated from the body of explosive by a distance determined by the speed and size of the projectile. When the nose of the projectile strikes the target’s armor, the contact fuze fires the primer, located at the rear of the explosive mass. If properly timed, when the detonation wave moves through the explosive, it will do so in such a manner that the force is mostly directed in towards the cone. This vaporizes the central material, and that material becomes a high speed, high temperature “Jet”. This punches metal, and can be sized for different penetration jobs. To the men inside of an armored vehicle, what comes through the armor is a concussion wave, and spall. Spall is molten metal and other remnants of the armor, and the effect is quite lethal. These projectiles can be used to destroy material, or used as antipersonnel for the occupants of bunkers or armored vehicles.

The advent of the shaped charge in a projectile made it feasible to penetrate thicker armor plate. As armor grew thicker, it became necessary to have a projectile of larger mass to defeat it. The standard method of launching a high speed projectile from a rifle styled cartridge quickly reached the limits of recoil using a man’s shoulder as a firing platform. Every action has an equal and opposite reaction, and launching a large projectile at high speed can be damaging to a person. Every couple of years we see an example of this when a suppressor is placed on a fifty caliber rifle, and for whatever reason, is launched free of the rifle when fired. That mass of three or four pounds being sent downrange is unforgiving to the operator on the other end of the stock.

Options that were explored at the time were tube fired rockets that could be shoulder mounted (Bazookas), shoulder based spigot mortars (PIAT), and the recoilless rifle. The Germans experimented with the recoilless rifle principle, and the United States had an earlier example to draw from with the Davis gun of World War One. Davis used a mass of shot moving to the rear that equaled the mass of the projectile, with the forward velocity factored in (This is not a one for one ratio). Recoilless rifles work with propellant gasses escaping in the opposite direction of the projectile launch, as opposed to a solid shot.

Swedish engineers at the state factory first designed the Model 42 recoilless rifle, which fired a 20mm projectile. The long case designed for the Model 42 was necessary because the rear of the cartridge case needed room for expansion of the burning propellant gasses, before blowing out a specially sized vent in the cartridge base. Each cartridge case had its own vent system, but the main exhaust tube of the Model 42 had a restrictor vent system of its own, that tends to burn out very quickly. This required replacement after about thirty rounds fired, and if it wasn’t replaced, the system became unbalanced and very dangerous to the operator. The work on the short lived Model 42 was done in the early to middle years of World War Two.

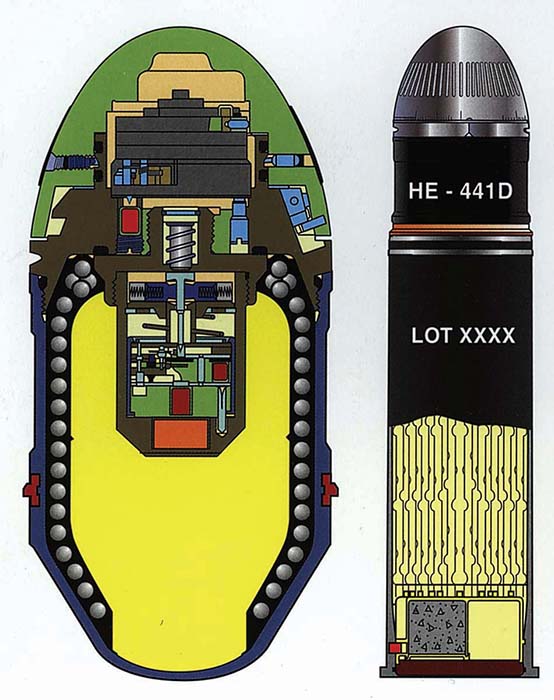

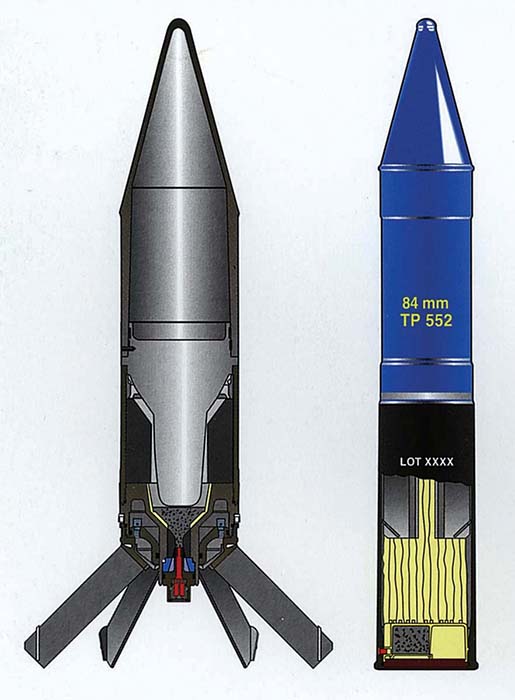

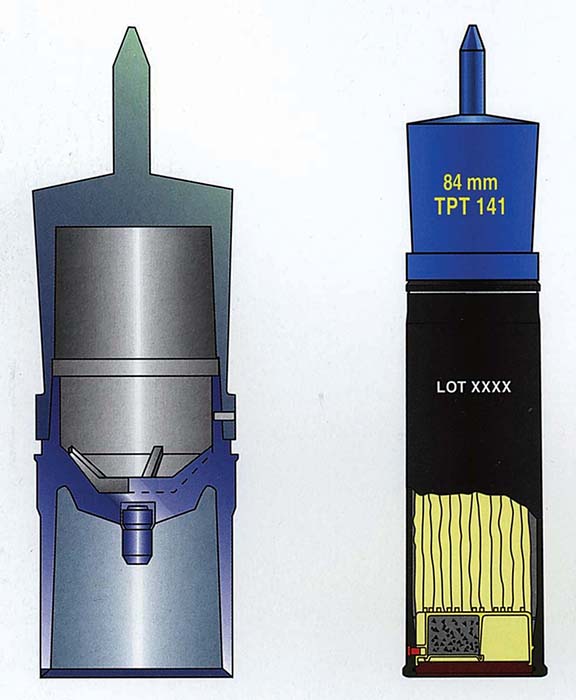

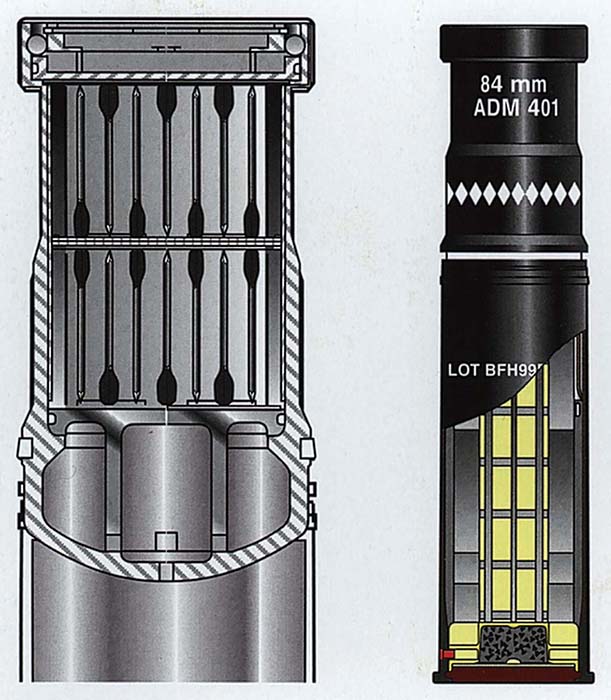

In 1944 through 1946, the state factory started work on a new prototype system using what appeared to be artillery shells. The outer appearance is deceiving; these are quite different from ordinary cartridges. Caliber is 84mm, and the system is no longer dependent on a cap restrictor system, there is a Venturi cone at the rear for the release of the counter recoiling gases. Each cartridge case has a blow out plastic section in the base, corresponding to the Venturi.

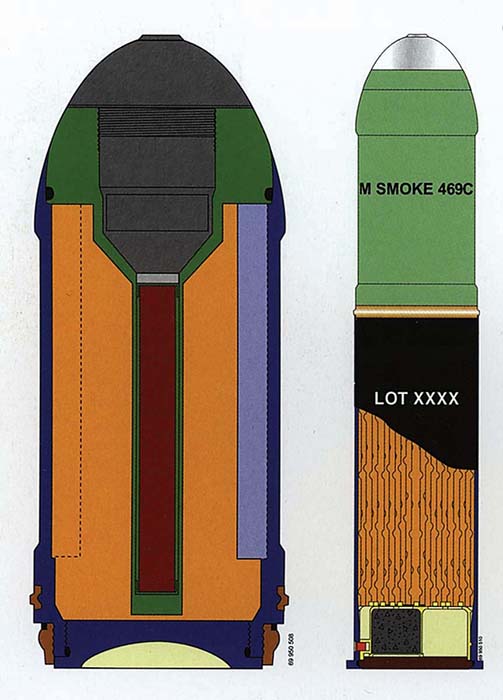

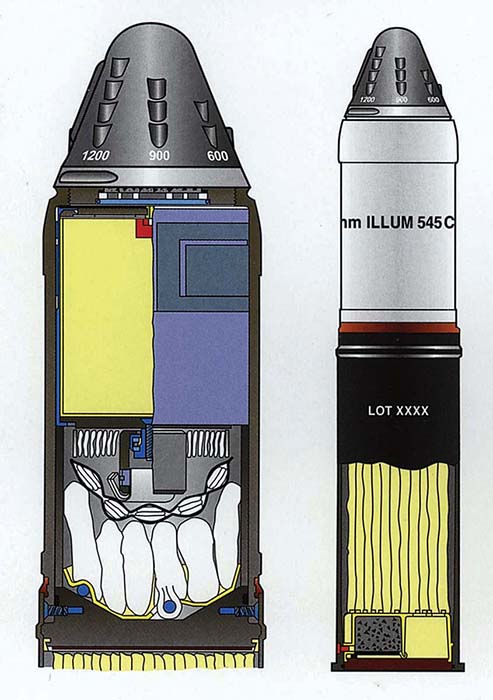

The M1 was the first prototype system, and the Carl Gustaf M2 84mm Recoilless Rifle went into production in 1948. This was originally designed as an anti tank weapon, but with innovation and experimentation, the uses were expanded. Manufacture changed over to FFV Ordnance, and then to the current ownership. The current lightweight version is the M3. We have a section describing the modern ammunition which all share the characteristic cases described elsewhere in this article. Suffice it to say, there are air bursting anti personnel rounds, anti armor, anti bunker, illuminator, and flechette rounds. The Carl Gustaf 84mm M3 system as presented today is versatile, and allows small infantry units a multitude of lightweight, effective options on the battlefield.

Recoilless?

Recoilless systems are touted as exactly that- a system of firing a projectile that does not produce recoil on the platform used in firing. This is accomplished utilizing a system that counterbalances the forward motion of the projectile, from the point of view of the platform. The operator is frequently the platform in recoilless systems.

Americans generally think of a recoilless rifle as one that has a chamber with larger dimensions than the cartridge, and the cartridge is suspended inside that chamber with equal space around it. The projectile is firmly placed into a rifled barrel, the cartridge case is perforated and not touching the chamber walls, and the cartridge base is firmly supported against the breech block. The breech block has vents of carefully determined size, opening to a conical main vent at the rear. When the rifle is fired, the ignition train burns, and the main propelling charge ignites. This charge is contained in a tube central to the cartridge. As the burning propellant gases expand, they not only fill the cartridge case, but due to the perforations, they fill the oversized chamber. Pressure builds at a predetermined rate, and the projectile is driven forward in the rifling, then down range. A mass of propellant gases is vented in such a manner as to counterbalance the recoil that would normally be quite severe. Every action has an equal and opposite reaction. Hurling a five or six pound projectile downrange at speeds of 900 plus feet per second could cause some serious damage to the shooter. That is why it is critical that the system be properly balanced.

In the Carl Gustaf M3 84mm Recoilless system, there is a combination of events that change the basics we are familiar with. First, and most importantly, the venting system is built into the cartridge. This means the chamber walls support the cartridge case. The projectile is fit into the rifling, the cartridge is supported and the base of the case is supported by the outer ring of the Venturi, what could be referred to as a “Breach”. The cartridge base has a plastic blowout that moves the properly metered gases out to the rear, through the Venturi cone. There is no venting or metering system in the Carl Gustaf M2 or M3 tube, it is all contained in the cartridge case. Thus, no perforations in the case walls, and the difference in outward appearance from a “Standard” recoilless cartridge.

Many U.S. groups are starting to use the Carl Gustaf M3, including the U.S. Army Rangers, and the U.S. Air Force is using the system as opposed to mortars for base area defense. The M3 provides a man portable platform that has many options, as evidenced by the ammunition available. This system is tried and true to many armies around the globe, and has a long, successful history. The quality controls at the manufacturing facility in Eskilstuna, Sweden, were superb. The care that goes into manufacturing translates into reliability on the battlefield. Saab Bofors Dynamics AB, the current owners of the facility and contracts, has opted to keep the same high quality in their process, and it shows in the end product.

SAR would like to thank Mart Pella from Nammo for his help in facilitating this article. We also thank the following people from Saab Bofors Dynamics AB for all of their help in tracing history and technology of this project: Åke Eckström, Director, Head of Small Arms Production Jan Arvidsson, Team Leader of Small Arms Assembly Department

Contacts Saab Bofors Dynamics

SE-691 80 Karlskoga

Sweden

bofors@dynamics.saab.se

Phone:+46 (0)586 810 00

Fax:+46 (0)586 857 00

www.saab.se/dynamics

| This article first appeared in Small Arms Review V7N6 (March 2004) |