Tippmann 1919 M37 with ammo can and 50-round belt. Photo by Jeff W. Zimba

Text and Photos by Jeff W. Zimba

Imagine a Model 1919 .30 caliber Browning machine gun as the centerpiece in your den or living room. Convincing your spouse that it is “art” and deserves to be on display rather than locked in a steel gun safe would be a tough sell for most, but may be a little easier if it is one of the Tippmann models.

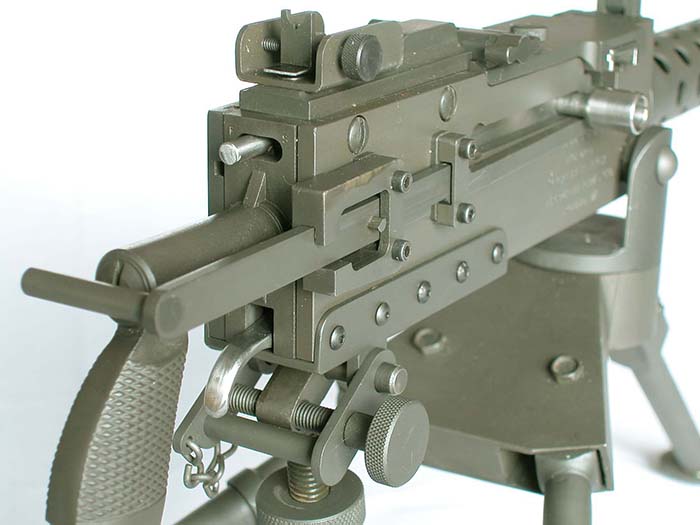

Tippmann Arms miniature firearms are fully functional, firing, 1/2-scale models of the famous Browning machine guns. Chambered in .22 Long Rifle, .22 Magnum and most recently .17 Hornady Magnum Rimfire, they are belt-fed just like the originals. They are identical to the original Brownings; and the detail in which they are manufactured and assembled is nothing short of amazing.

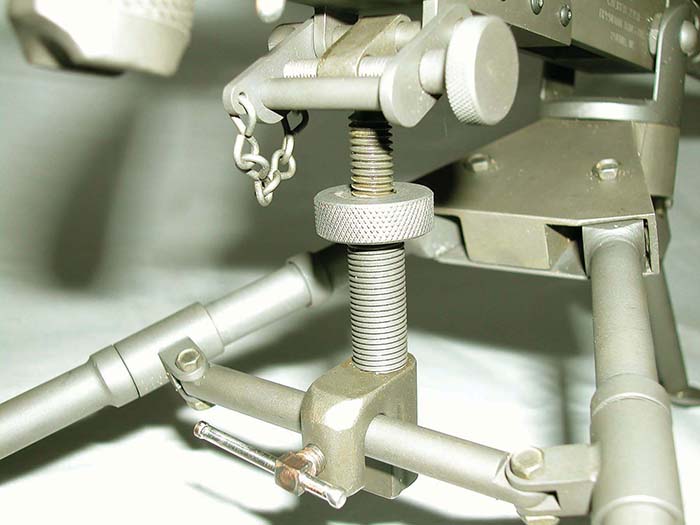

Each model is shipped in an oak chest, with a 1/2-scale tripod and a fully functional traverse and elevation mechanism. A miniature owner’s manual, two miniature ammunition cans and two belts are also included with each model. One belt holds 25 rounds and the other holds 50 rounds. Models available in .22 long rifle include the 1919A4, the 1917A1 and the 1919 M37. The M37 is a variation of the 1919A4 that utilizes a rear cocking handle. The M2 Heavy Barrel and the M2 Water Cooled variants are available in either .22 Magnum or .17HMR. All new models available for sale to individuals are manufactured in semiautomatic-only. Post 86 dealer samples are also available to government agencies, Class III Dealers and Title II Manufacturers.

Eric Graetz of Lakeside Guns personally builds each of the current Tippmann miniatures. The parts are CNC machined to exacting tolerances. The vast majority of the earlier Tippmann miniatures were built from investment cast parts. Although the new parts can be used to repair and rebuild the older models, they must be hand fitted.

A total of 123 full-automatic Model 1919’s and either 42 or 44 full-automatic .50 caliber models were manufactured prior to the 1986 machine gun ban. If you look at the serial numbers on the early guns you will notice the prefix of either “FA” or “AL”. The “FA” prefix simply stood for “Full Auto” while the “AL” prefix abbreviated “After the Law” making reference to the 1986 ban on manufacturing new machine guns for sale to individuals.

Ammunition belts were originally manufactured from an elastic fabric, similar to the fabric used in the waste band of underwear. These stretchy belts had staples between each pocket designed to hold a round of ammunition. The second generation of belt material was a plastic banding material with a slit cut to hold each round. The latest generation of belt was made from a woven fabric with intermittent stitching, designed exactly like the original, full size belt. These belts were even made on an antique weaving loom. This last generation of belt was produced in late 1984 and offered for sale in January of 1985.

These belts were purchased on 250-foot rolls. When this material could be cut into new belts (before the Assault Weapons Ban of 1994) the customer could request any length belts they desired. The most common length was a 100-round belt, which was almost a perfect yard in length. Although not common, 150-round belts, 250-round belts and even 500-round belts are known to exist. Eric currently has one belt that is 93 feet in length and holds approximately 3,100 rounds. (Please note that he did not send this belt to the author along with the test specimen. This was probably a good move on his part).

Due to the 1994 Assault Weapons Ban, new belts in lengths of over 10 rounds are no longer legal to manufacture for individual ownership. Lakeside Machine currently has less than 3 rolls of cut belts in their possession. None are for sale at this time so they may be enough to be provided with each new firearm currently manufactured and sold. If the ban is allowed to sunset as it was intended in 2004, Lakeside Machine will be making new belt material in any lengths requested. If the ban does not sunset they will be marketing a belt-making machine so the consumer can make their own 10-round plastic belts.

Care and Feeding

The basic function of the Tippmann miniatures is almost exactly like that of the original, full-size Brownings. The mechanism used to feed the belt, extract a round from the belt, chamber the round and extract the empty casing is very much the same as the originals. The difference is that the miniatures do not utilize locked actions. This small mechanism requires all the energy it can get from the rimfire cartridge in order to complete the tasks listed above and a locked action would create the necessity for more energy.

The operator will notice that after firing the last round in a belt, the action will be slightly rearward and there will be an empty cartridge between the face of the bolt and the breech surface. The reason for this is that the new round being pulled from the belt slides down the face of the bolt in the “T-slot”, pushing the empty round out. When no new round is being inserted there is nothing to push the last round out of the “T-slot”. Opening the top cover, retracting the bolt and pushing the casing through the bottom of the action with your finger will clear the casing.

As with any .22 rimfire firearm, the greatest enemy of the action is powder fouling and the waxy buildup from the bullet. The best friend of the Tippmann miniature is simply a toothbrush and a good solvent. Lifting the top cover and pulling the bolt rearward allow the shooter easy access to the bolt face and breech area for simple cleaning. If the guns are kept clean and lightly oiled they will function very well. In asking Eric about the number of rounds one can expect to fire before encountering failures, he reiterated the points above, and claimed to have fired over 2,500 rounds through one of his test guns before having to scrape out the bolt face and breech area.

The .30 caliber miniatures are manufactured to feed and function correctly with subsonic ammunition. This makes the addition of a suppressor that much more desirable.

The test specimen that I had for evaluation worked perfectly. I used Blaser ammunition (lots of it) and it had a hearty appetite for it. There was never a time it was out on the firing line without causing a crowd to gather and start pointing fingers and asking questions.

The tripod and T&E mechanism function well under live-fire conditions. The gun does not jump around and is held on target for the duration of the belt. The adjustments are very smooth and gradual and everything locks up very positively.

What ARE the Tippmanns classified as?

Give this a little thought. These miniature belt-feds don’t seem to fit in any current category of firearms as defined by the ATFE. The .30 caliber Browning models of the Tippmann firearms are not classified as pistols. They were not designed to be, nor can they be, physically fired with one hand. They are not rifles as they cannot be fired from the shoulder and they have barrel lengths shorter than 16 inches. Although they don’t seem to fit in any specific category, the semiautomatic variants are sold and treated like standard Title I firearms. In the early stages of development in 1983, the BATF ruled that even though they didn’t seem to meet any of the standard criteria they could be treated just like a standard Title I firearm. The one stipulation to this ruling was that the pintle would have to be permanently riveted to the receiver; therefore the tripod would always be attached, making it “less concealable”. This ruling only pertains to the miniature .30 caliber variants, as the miniature .50 caliber models have barrels that are 18 inches and the overall length is 26.5 inches so they are treated as regular rifles. Due to these strange characteristics the Tippmann models are just placed under the category of “Title I Firearms” and are still manufactured under the current “assault weapons” ban without consequence.

Miniature Accessories

There are many accessories that have been manufactured for these miniature firearms. Lakeside Machine has manufactured 17 belt-loading machines since their acquisition of Tippmann Arms. Eleven of them are for the .22 long rifle and six are for the .22 magnum and .17HMR belts. These were designed to replicate the 1918 belt-loading machine, including a variant of the original carry crate. There were also a few loading machines manufactured by Dennis Tippmann in the 1980s. These original loading machines were a very simple design and were not manufactured to resemble any original belt-loading machine. It is believed that two loading machines were manufactured by Martin Tippmann to resemble the 1918 loading machine, complete with feed needles and an exact replicated mechanism, but the whereabouts today are not known.

A very early brochure illustrated the model 1919, serial number 22, complete with 1919A6 accessories. That was the only set of 1919A6 accessories to be manufactured for the Tippmann miniatures. BATF disallowed them as the kit changed the classification of the miniature 1919 to a Short Barreled Rifle.

A single shoulder stock for the M2HB was manufactured and sold at the SOF convention in 1985. It remains in a private collection.

Spade grips for the 1919 and 1917 models have been added to the items available as of late. Flash hiders for the M2HB models in both .22 magnum and .17HMR can be purchased from Lakeside Arms as well as miniature “US”-marked display sandbags and wooden ammo boxes for the 1917’s. Spare barrels in .17HMR can be purchased to convert the caliber of original M2HB 22 magnum guns and the 1919 A4 models now have the option of using sound suppressors. The suppressor simply replaces the muzzle nut and heat shield support.

Future Projects

As you read this there are a few new projects on the horizon for Tippmann miniature enthusiasts. Eric is currently experimenting with a right-hand feed M2. This means the possibility of twin mounts or even quad mounts. Other future projects include Tombstone drums, a correct tripod for the 1917A1 series and even a standing M63 mount for the M2 series. There may even be a miniature Maxim or Vickers in the future. We can only hope.

Lakeside Guns

N5391 County Road S

Pound, WI 54161

(920)897-4682

Sales@lakesideguns.com

www.lakesideguns.com

Tippmann Company History

In 1983 Dennis Tippmann, with assistance from his brother Martin Tippmann, started the original Tippmann Arms Company. The design for the original semiautomatic-only Tippmann was approved by BATF on June 27, 1984. Initially offering only the 1919 and the 1917 models, they added the M2HB in January of 1985.

On June 24, 1987 Tippmann Arms Company was purchased by F.J. Vollmer and Company of Plainfield, IL. The following serial numbers were purchased in this transaction: 1919A4 Models – AL116, AL120 through AL153, AL155 through AL158. Not all were completed before the transaction. 1917 Model – AL176. M2HB Models – FA67 and FA69. Many of these guns were not completed and F.J. Vollmer and Company almost immediately started to market the side plates acquired in the buyout.

On September 13, 2001 Eric Graetz of Lakeside Machine in Pound Wisconsin purchased Tippmann Arms from F.J. Vollmer and Company. Eric has been a fan of the Tippmann miniatures since one appeared on the cover of Guns & Ammo in their January 1985 issue. He purchased his first miniature in 1993 and immediately began making accessories such as ammo can holders and miniature sand bags for it. Deciding to start selling these items to other Tippmann enthusiasts, he placed an ad in the now defunct Machine Gun News magazine and soon started being contacted by several other Tippmann collectors.

After compiling a complete set of the three semiautomatic-only variants and the three fully automatic variants his interests turned toward collecting brochures and paperwork relating to the miniatures and soon found himself in contact with Dennis Tippmann. Eric’s interest and knowledge kept growing in the Tippmann Arms field and led to his eventual purchase of the company from F.J. Vollmer and Company.

| This article first appeared in Small Arms Review V7N6 (March 2004) |