By Michael Shyne

How does a restoration project begin? In my case it involved three long wooden cases, part of a purchase of a Title II firearms collection. The seller told me what they were: .50 caliber Brownings. No problem, I’ll get some tripods and have them complete and ready to go in no time. Not so! When I opened the cases I discovered something very different than I imagined: 3 original water-cooled .50 caliber machine guns, two manufactured by Colt and a third an original Hi-Standard, with its original HiStandard-manufactured water jacket! Okay.

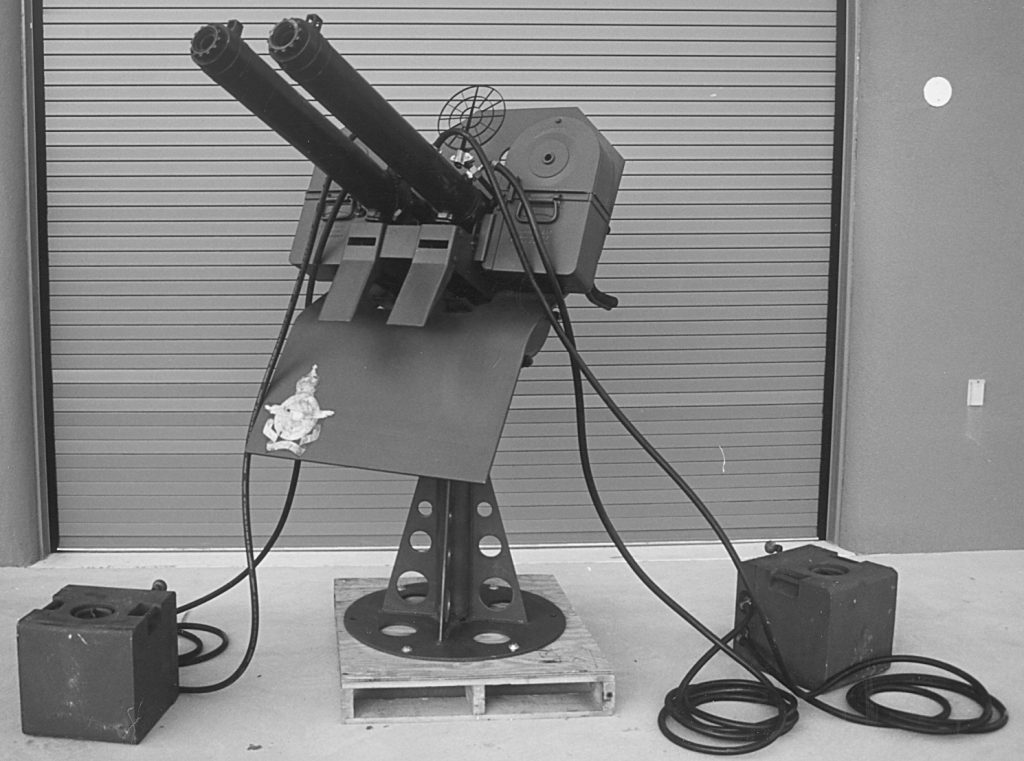

The first thing I did was call Robert Segel who authored two articles on the subject of water cooled fifty caliber machine guns, one in the now defunct Machine Gun News (February 1990) and another in Small Arms Review that touched on the subject (August 1999, Volume 2 Number 11). This was the only post World War II source of information on this subject known to this author! Robert assured me there were only 21 known complete, original, live water-cooled .50s in the country. In addition, he did not believe Hi-Standard made the water-cooled version. Robert’s article featured the M3 anti-aircraft mount, a 400-pound beast appropriate to the water-cooled 50. Finding them proved impossible. Most of these mounts were trashed many years ago because there was no demand and they were just too heavy. Ryan is a water-cooled .50 owner in Texas. He directed me to Rapco, a company specializing in parts and paint for the restoration of military vehicles. By the utmost good fortune, they had a twin 50 shield mount removed from a World War II halftrack.

This mount turned out to be a Navy mount designated “Mark 22 twin pedestal mount for machine gun caliber 50 Colt Browning”, made by Heintz Manufacturing Company in Philadelphia. It was also designated the “Mark 15 50 carriage”, with both designations on shiny brass I.D. plates. What about the Hi-Standard? For that I was able to locate a single U.S. Navy .50 caliber shield mount.

The three .50 caliber water-cooled guns were generally complete but lacked some of the small parts unique to the water jacket. A Colorado collector sold me something from his parts pile, a complete 50 caliber water jacket assembly. That wasn’t exactly what I was looking for, so now I had the makings of four water-cooled guns and decided to convert a World War II .50 caliber machine gun manufactured by A&C Sparkplug from its air-cooled configuration to the water-cooled configuration. Four guns meant I needed another mount.

The next step seemed obvious: disassemble everything, have it sandblasted, paint it and put it back together. Today, the mounts released by the government are totally demilitarized, cut into little pieces that are worthy of nothing but the smelter. If you are lucky, you will find an old one that was not demilitarized. More likely, you will locate a mount that has come under the cutting torch, but can be restored. The mounts I had obtained fell into this category.

Disassembly sounds easy. Everybody has a few wrenches, a hammer and some WD-40. But before you start taking your mount apart, do two things. First, photograph it so you can remember how it goes together. Secondly, obtain the technical manual for the mount. For the water-cooled gun this was not easy. Both Robert Segel and Dan Spears sent me a xerox copy of the 1943 War Department TM 9-230 “Machine Gun Mounts for Boats”. It covered the M39 pedestal mount for the single .50 caliber air-cooled anti-aircraft configuration, the M43 pedestal mount for the single water-cooled anti-aircraft configuration and the M46 anti-aircraft mount for twin .50 caliber water-cooled guns. Although my twin mount was designated the Mark 22, probably a predecessor to the M46, and my single mounts were a successor to the World War II M39 and M43 single mounts, this technical manual proved priceless.

You want the steel reconstruction to be done well, but keep one thing in mind. Don’t become a perfectionist. The manufacturer of this mount wasn’t one and the imperfections of steel refabrication need to be no better than the initial construction of the mount. Paint covers a multitude of sins.

After complete disassembly, clean all of the parts thoroughly to remove grease, grime, sand and everything else that builds up in the crevasses of these old mounts. I found my pedestal bases to be full of grease mixed with sand. The only good news is that there are vent holes in the bottom of the pedestal that facilitate the process. My assistant made a tool out a short section of 31/2-inch OD pipe, by welding a long rod as a handle. This worked as an excellent scraper, allowing the years of buildup inside the pedestal spring housing to be scraped away.

Before taking everything to the sandblaster, lay all the parts out in an orderly fashion. Some parts don’t need to go to the sandblaster, and furthermore they are too small. Clean them yourself. Others may not be worth trying to reuse. This particularly applies to rusty bolts, washers and the tubular iron spacers that fit between the side plates of the mount. These spacers are nothing more than 3/8-inch ID or 1/2-inch ID iron pipe available at your local plumbing shop. New bolts, nuts and washers can be obtained at the hardware store. Their zinc coating will dissolve after immersing your parts for a few minutes in muriatic acid, also available at your hardware store. (Read and follow the instruction carefully, this chemical is dangerous and highly caustic). Wear eye protection and rubber gloves, use the chemical where its fumes will not become your next breath, and thoroughly wash all of the parts after they have been removed from the acid. Avoid leaving puddles of the acid for children or pets to step in. After this process, these parts will take paint well.

Some of these parts should not be sandblasted and others have delicate surfaces that need to be protected. The ball bearings and bearing races should be cleaned and carefully stored until reassembly. The races are generally numbered as a pair. If you are wise, when you disassemble it, you will note which one was the top bearing race and which was the bottom race, in order to reassemble the bearing group exactly the way it was put together by the manufacturer decades ago. One of the most critical parts is the bearing retainer. These are cast iron, very similar to piston rings in automobile engines. Too much twisting or flexing and they will break. Do not even try to remove or replace the bearing retainers until all surfaces are spotlessly clean down to raw steel, with no surface damage that will interfere with movement. Lightly lubricate all surfaces after they are cleaned, to facilitate removal and installation. Using a brass rod, carefully tap around the retainer, moving it only fractions of an inch so as not to cause much vertical twist. Cast iron rings can snap very easily. These will not be replaceable.

The pedestal socket is a complex brass casting. On the M46 twin mount I had planned to leave it unpainted, polishing it so that it would show off the beauty of the old brass alloy. However, its casting surface was too coarse and I chose to paint it, as it was originally. I was able to preserve the beauty of the brass on the single mounts after sandblasting the paint away with a very fine abrasive. Tell the sandblaster what you intend to do and he will know what to use. The surfaces were then polished using a simple wire wheel on an air powered die grinder. To preserve the color afterwards, they received a couple of coats of clear lacquer.

In my case, the sandblaster was able to paint the parts as well. I used Sherwin Williams Kem Kromik Universal Alkaloyd metal primer over the raw steel. The color coat was an excellent quality oil-based enamel obtained from Rapco. I used semi-gloss World War II green enamel #595-23070-11LFD for two of the mounts. I painted one of them with Rapco’s Navy gray enamel #16081.

Protect and preserve any identifying marks, insignias, numbers and letters, even if you have no idea of their significance. A stroke of the sandblaster’s nozzle or an accidental coat of paint would have extinguished any opportunity I may have to identify the British Commonwealth insignia on the twin mount’s shield. With research clues like this, the actual history of a particular artifact may be discovered. Imagine being able to authenticate which battles a gun may have been in. That information can multiply its interest to posterity (and its value)!

Since they were sandblasted, these parts need to be thoroughly cleaned before they are painted. All dust must be removed or it will diminish the quality of the finish. However, the dust may not only be on your parts. On my first mount to be repainted, the outcome was rough and gritty, even though the parts were well cleaned before they were painted. We ultimately found the problem: a dusty painting environment coupled with slow-drying paint. Washing down the ceiling, walls and floor of the painting environment solved this problem before the other parts were painted. In addition, a drying agent was added to the paint so that it would dry much quicker, shortening the time the surface remained sticky and vulnerable to airborne particulates.

A lot of work, time and expense had gone into the project so far. Yet, avoid rushing reassembly, even though it is the most rewarding part of the project. Again, lay all the parts out in an organized fashion. If you photographed them before they went off to the sandblaster or the painter, you can check your pictures and make sure everything is there. It’s very easy for a small part to be accidentally lost while being refinished.

When assembling the side plates to the pedestal socket, you will want to leave the side plate spacer bolts and the carriage case deflector bolts all loose until everything is loosely assembled. Then use the gun mounting pins to establish final alignment before tightening everything. If you don’t obtain proper alignment, you will tighten everything up but you won’t get the gun to fit the mount. After the side plates are installed on the pedestal socket, defer installing the cartridge case deflector until the recoil shield is in place. Once it is loosely in place, you can tighten everything down. It seemed to work best for Byron to put the side plate recoil shield and pedestal socket together as an assembly. Then, as a unit, set it on the pedestal with the counterbalance spring, outer bearing ring, ball bearings, and bearing housing in place on the pedestal. In spite of the crudeness of the appearance of the mount, there was a lot of precision work that was done to make it function property. Excess paint or sometimes even a single coat of paint on precision-fitting surfaces, will prevent proper reassembly.

The counterbalance spring, a large coil spring that fits inside the pedestal tube, deserves your attention at this point. You have to decide whether you want to use this mount for air-cooled or water-cooled guns as the spring requirement is different. On the World War II manufactured guns, the true M39, M43 and M46 mounts, the springs are color-coded. The counterbalancing spring for the air-cooled single gun mount is painted green. The water-cooled single gun mount spring is painted black. The twin mount in water-cooled configuration uses a spring that is painted yellow. Fortunately, my spring was yellow and was designed to support the extra 35 pounds per gun the water-cooled machine guns add to the system, plus their leverage multiplier. The single mounts I was restoring were post-World-War-II and designed for air-cooled guns only. I was under the belief that I could adjust the spring compression rod and make up for the difference. Assembling the gun and mounting a water-cooled .50 convinced me I was seriously in error. To complicate matters further, the World War II mounts have a single long counterbalancing coil spring that rests on the bottom of the pedestal base within the pedestal tube. However, the post-World-War-II single mounts I was restoring had been “improved” by shortening the main counterbalancing spring used to offset downward muzzle motion, and adding a short counterbalancing spring to offset upward muzzle motion. Since my single mounts were assembled for air-cooled use and I intended to use them for water-cooled guns, I needed to obtain coil springs that were substantially heavier and able to counterbalance the increased downward weight. I chose not to add stiffness to the smaller counterbalance spring that offsets the muzzle-up movement.

Coil Spring Specialty in St. Mary’s, Kansas was willing to manufacture a spring to my specifications. I sent them the original spring for air-cooled configuration, along with a sketch quantifying the additional weight the water-cooled guns would add to spring compression, plus the length of the lever arm involved.

From the moment your eyes rest upon one of these mounts or for that matter virtually any shield mount, it becomes clear that the gun is one of the lighter and more easily maneuverable parts of this assemblage. Avoid risking back injury. The M46 twin mount weighs 825 pounds. The M39 or M43 single mount weights 725 pounds. A hoist system is absolutely necessary for the disassembly and reassembly of these mounts. This is particularly true because of the care required in their alignment. Moving these assembled mounts is an impossible task without bolting them on a pallet and using a pallet jack.

Even though your mount parts are beautifully refinished, you may have to give them a few strong licks with a heavy hammer to make them fit together. Don’t sweat it! The good news is that Rapco has the very same paint color in aerosol cans, a must for this type of work.

With the exception of the shoulder brace padding and the swing, most everything is steel, iron or brass. But the shoulder brace frames have rubber tubing attached to dampen the vibration of the gun. In the original configuration, the rubber tubing is held to the frames by a length of half-round steel with treaded holes aligning to the holes in the exterior portion of the shoulder brace frames. If yours are in good enough condition to remove all of the screws and replace the rubber, you are fortunate. However, if the half-round steel member, which fits internal to the rubber tubing, is badly rusted, an alternative exists: use steel reinforced hose, specifically 250psi Dayco steam lance hose, part #7263 from a Los Angeles supplier. The advantage of the steel reinforcement is that it provides a grip for the 5/16 inch by 1 inch long hex head self tapping sheet metal screws which are inserted into the holes in the shoulder brace frames. You can hide the steel reinforcement by giving the hose ends a coat of black windshield sealant. By using this system, you can avoid the half-round internals and still end up with a very pleasing and functional result.

Frequently the shoulder brace frames have been lost from the surplus mounts. Making authentic replacements is not easy task. Dan Spears was in that predicament and made two, plus an extra for me.

Finally the great moment has arrived: mounting the gun. I wanted to make certain the new counterbalancing spring was appropriate, so my assistant and I filled the tombstone ammo can with 200 rounds of live ammunition and mounted it.

The single mounts I restored were clearly designed for the air-cooled guns, allowing the gun to be mounted from the rear of the mount without disassembly of any parts from the gun. The hole in the post-World-War-II shield through which the gun protrudes was smaller than the similar space provided in the M46 twin mount. However, it is possible to mount the water-cooled guns on the post-World-War-II single mounts by removing the cocking handle and possibly the spade grips and rear sight, and gently guiding the gun into place from the front of the mount. After the gun is secured in place, reinstall the parts you have removed and the gun will function properly. The World War II M46 twin mount has wider gun ports, but it is still easier to install the guns from the front of the mount.

With the water-cooled gun in place on the single mount, I attached the water hoses and the water chest (the water pump used to circulate water through the water jacket). This was the great moment. The joy of seeing the completed project was certainly worthwhile!

Symmetry always appeals to my aesthetic judgment. The twin gun is no exception. Two tombstone ammo cans, two pairs of hoses, two water chests and of course, two big black 50 caliber Browning machine guns with 45-inch water jackets sure add a lot of life to the M46 twin mount.

Project Complete. One more piece of our nation’s 20th century history preserved for future Americans. This is an example of why so many of us in the Class III world collect what we collect.

Coil Spring Specialties

632 West Bertrand

Dept. SAR

St. Mary’s, KS 66536

Phone: 785-437-2025

Attn: Dave

The Supply Depot

Rural Route 14, Box 1100

Dept. SAR

Bedford, IN 47421

Phone: 812-275-2801

Attn: Jim Lawyer

Rapco Parts Company

P.O. Box 191

Dept. SAR

Bowie, TX 76230

| This article first appeared in Small Arms Review V6N6 (March 2003) |