Right-hand profile of an early “00” series XL60 individual weapon. Serial number 001.

By Jonathan Ferguson, Photography by N.R. Jenzen-Jones

The XL60 series of experimental firearms was the first generation of what was initially known as the “485 Weapon System,” designed and produced at the Royal Small Arms Factory (RSAF) Enfield, located in North London, United Kingdom, by a team led by Sydney Hance. The term “485 Weapon System,” so-named for the weapon’s 4.85mm calibre, was later dropped in favour of “Enfield Weapon System” or EWS, which persisted until at least 1982 but was ultimately also side-lined. Instead, the name “Small Arms of the 1980s” or “SA80” was adopted and remains in use to this day. This term is used alongside the land service or “L” designations (e.g., L85A2). Interestingly, this name was in use from the very beginning by the British Ministry of Defence (MoD), sometimes with the prefix “Section” as in “infantry section” or squad. As per the preliminary study and MoD specification, the EWS/SA80 system comprised rifle and light machine gun variants, known by their period NATO euphemisms of “Individual Weapon” (IW) (today simply “Rifle, 5.56mm”) and “Light Support Weapon” (LSW) (a term still in use today, sometimes considered interchangeable or overlapping with “squad automatic weapon,” or SAW; automatic rifle; and light machine gun, or LMG). Several variants emerged during development which all received their own designations. This can get confusing, so these official designations are detailed here:

- XL64E5—the Individual Weapon (IW) standard rifle in a right-handed configuration;

- XL68E2—the rifle in its left-handed configuration;

- XL65E4—a “Light Support Weapon” aka “Machine Gun” variant (LSW/MG), right-handed;

- XL69E1—“Machine Gun” variant, left-handed.

The “00 series”

However, this is jumping the proverbial gun somewhat, as there are two earlier iterations of these prototypes that should be first discussed. In 1972, British Ministry of Defence followed on from the preliminary study covered in the previous article. By this time, it had been decided that the new weapon family would be a modern bullpup in a small calibre high velocity (SCHV) calibre. As covered previously, the gas system and working parts of the new weapon were very closely based upon an existing and straightforward design—the Armalite AR-18. This should have shortened and eased the development process, but this was not to be. The author’s strong impression from having read a great deal of material in the Pattern Room archive and extensively handled and stripped the weapon is that every effort was made to design an original, British weapon that would take the best features of contemporary weapons, just as Kalashnikov’s team had done in the Soviet Union (albeit with a great deal more success). These features include:

- Ammunition of 4.85mm calibre. This was based upon the U.S. 5.56x45mm cartridge, with an elongated case containing a longer, slimmer bullet (of identical 55 grain weight) thought to exhibit better performance (it certainly demonstrated better penetration than the M193 at range) and reduced recoil.

- Lightweight, “unorthodox” or “buttless” (i.e., bullpup) configuration, capable of conversion at the unit armourer level for left-handed users.

- An optical sight equivalent or better to the existing Sight Unit, Infantry, Trilux as fitted on a designated marksman basis to the L1A1 SLR (FN Herstal FAL).

- Provision for a night sight.

- Area target capability (achieved through rifle grenades or underbarrel launchers).

Despite the pre-existence of the Steyr AUG and FAMAS bullpup self-loading rifles with their convertible left-/right-handed design (and claims in the gun press to the contrary), the SA80 family was never made “ambidextrous” and relied upon different variants to meet this user requirement. None of these could be converted without replacing the entire barrelled upper, nor could they be fired from the opposite shoulder without risk of injury, specifically the cocking handle striking the user in the face (to say nothing of hot brass cases). In the event the requirement was dropped and all soldiers taught to fire from the right shoulder; nonetheless, from the outset both rifle and machine gun were intended to be made available in left- and right-handed versions.

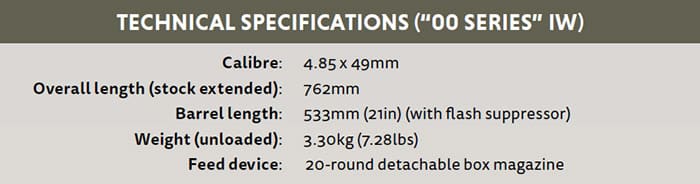

This first batch of developmental weapons were not “type classified,” but in terms of design lineage we will treat them as part of the XL60 series, which in turn is a phase of the EWS/SA80 project. The first 12 prototypes made were known as the “00 series,” despite the fact that 12 were made (001–0012). Eight of these were IW (rifles) and four were LSW (light support weapons). The first prototype ever made is marked “R No. 001” on the upper receiver (“body”) and “No. 001” on the lower (“trigger mechanism housing” or TMH), one of three examples in the Royal Armouries ex-Pattern Room collection. The “R” stands for “Rifle,” while the LSW bears an “L” prefix for “Light Support Weapon,” despite being interchangeably referred to at the time as a “Machine Gun.” One of the IWs was produced in 5.56x45mm in an early acknowledgement that 5.56 already existed as a rival, and the new design might require conversion at a later date (as the EM-2 had to 7.62x51mm). Contrary to a claim in Raw’s book, this was built in 5.56mm and was not later converted as part of the XL70 family.

The Sterling Conspiracy Revisited

We have previously debunked the claim that Enfield built their AR-18 bullpup conversion from parts stolen from the rival Sterling factory. Indeed, while Enfield might be argued to have borrowed rather heavily from the AR-18, they did not do so from Sterling, who had yet to begin production of the AR-18 when Enfield first designed the weapon. However, there is another related myth pertaining not to the converted AR-18 but to the actual Enfield prototypes in the “00” series. This appeared in The Observer newspaper at the height of the controversy over the in-service SA80 in 1992: “In 1976 Edmiston and his designer, Frank Waters, saw the prototype SA80 at the British Army Equipment Exhibition in Aldershot. It was a bullpup design, a squat rifle with a minimal butt, and its operation looked curiously familiar.”

“Frank was allowed to take it apart,” Edmiston told The Observer. “He found our bolt carrier, our magazine and parts out of our gun. These weren’t even copies. They had bought some of our guns and were using the parts to make the SA80 prototype.”

A former weapons designer with Royal Ordnance confirmed that claim. He added that the original prototypes, basically an amalgam of the Armalite AR-18 and the bullpup design of the old RO EM2, were good, promising guns, “but the design was fiddled with by committees in the MoD and Royal Ordnance.” The gun, he says, “has never been the same since.”

This is impossible. The prototype shown at the exhibition was the “00 series” gun; mechanically based on the AR-18 to be sure but containing no interchangeable parts. In fact, this may be a misquote on the part of the Observer journalist. In his own autobiographical book The Sterling Years, also published in 1992, Edmiston states that the Enfield director toured the factory in 1979, but only “some three or four years later” did Frank Waters inspect prototype SA80s. In this account Waters does not suggest that the parts were actually Sterling-made, simply that they were close in design, which is quite true. The similarity of the AR-18 and EWS/SA80 working parts and gas parts is interesting to be sure, but hardly unique in the history of small arms design (as noted in a previous article). Indeed, neither these parts nor any other feature of the Enfield were in breach of Sterling’s, nor Armalite’s, nor IP.

Armalite was granted a detailed patent for the design of the AR-18 in a number of countries including the UK (GB1056056 (A)) and the U.S. (U.S.3318192 (A)), though only the 1967 UK patent is relevant here. In the UK, patent duration is 20 years; meaning that this one was still in force when the EWS/SA80s were being produced. Yet it is the specific nature of Armalite’s patent claims that make them irrelevant here. Because each claim describes their design in detail, a given weapon would have to be a near-identical copy to risk infringement. Enfield clearly knew this, since they made no attempt to hide their inspiration. Hance even patented the EWS design with direct reference to one of Sullivan’s patents; although for some reason he cited the 1964 patent for the AR-18’s folding stock design and not the actual 1967 patent covering the receiver architecture of the AR-18. This is very odd given that the Enfield (as a bullpup) had no buttstock. It is also noteworthy that Armalite did not attempt to patent the AR-18’s gas system, only a reciprocating bolt carrier with a rotating bolt, and only where this was installed in a receiver matching their precise architecture (to which, if anything, the Sterling LAR and SAR-80 are much closer).

Design Features

Controversies aside, the basic design of the 00 series guns goes a long way toward meeting the original requirements, being neat, compact and lightweight (especially without the hefty SU.S.AT). It balances well in the firing hand and is easily manipulated. Aside from the inevitable ergonomic issues presented by the bullpup configuration, it is an obviously early effort. The cross-bolt safety is located conveniently enough but is small and yet at the same time easily pressed inadvertently. The magazine catch is located on the wrong side of the weapon and rocks in the wrong direction for easy manipulation with the left (support) hand. The cross-bolt selector is easy to operate, but inconveniently located at the rear of the receiver.

Also, because “R” for “Repetition” (see Editor’s Note at end) is in the centre position, it is possible to accidentally place the selector on either the “A” (to the left, for Automatic) or “3” (to the right, for three-round burst) position. The small bolt handle lacks the AR-18’s upswept profile, making it harder to cock with the support hand than it might otherwise be (most likely to prevent the firer’s arm being struck during hip fire). The adjustable gas plug is marked “E,” “R” and “0.” E is for “Excessive” and “Zero” for launching rifle grenades. “R” is a mystery, as the provisional manual produced for this series does not clarify this detail. As this setting on later patterns is “N” for “Normal,” perhaps here “R” stands for “Regular.” The weapon is easily disassembled for cleaning with the removal of one captive pin and a sprung retaining band on the handguard. However, the hammer must be manually depressed with a tool in order to reinstall the bolt and carrier.

Overall, this early SA80 prototype typifies period small arms design and manufacturing principles, being of spot-welded, pressed (stamped) steel construction with synthetic furniture and featuring the optical sight and SCHV requirements already noted. The finish is black paint over phosphate, with bluing for the optical sight and mount. The magazine catch, handguard retainer and butt-plate are simply painted black. The grey polymer handguard and pistol grip are roughly machined from solid polymer (glass-reinforced Nylon 12 polyamide), the former having four widely spaced finger grooves and the latter being similar in shape and grip angle to the AR-18 original. The butt-plate is now a custom piece and is deeply grooved. There is no cheekpiece, and no dust cover is yet provided. As has been noted, the working parts are very close to those found in the AR-18 but despite claims to the contrary, have not been directly copied and differ in every detail. Unfortunately, this includes a very weak bolt head; a feature actually borrowed from the Stoner 63 bolt. The trigger mechanism too is substantially different to that found in the AR-18. As well as the long trigger bar required by the bullpup arrangement, every component of this assembly is of a different shape and arrangement. For example, in the AR-18 the disconnector is located at the rear of the mechanism and protrudes through the middle of a (slotted) pressed steel hammer in order to hold the latter back during cycling. In the EWS, the same component (the “sear interceptor” or interceptor sear) operates on a bent in the bottom of the cocked hammer, which is a differently shaped solid casting and is therefore positioned beneath it. Because it is adapted from the AR-15’s trigger mechanism but uses a different, shorter bolt carrier, the AR-18 uses a long, two-part auto sear assembly that is anchored to the selector axis pin. The EWS uses a simpler, more purpose-designed, single-piece lever (“safety sear”) pivoted on the trigger axis pin.

The barrel is of similar “pencil” profile to the AR-18 (and indeed contemporary AR-15/M16 rifles), but that weapon’s pronged flash suppressor was abandoned in favour of a pseudo-cone-shaped design reminiscent of the PKM device but featured three large ports in front of a second annular ring. The weapon is fitted with a prototype SU.S.AT sight (retrospectively designated XL9E1) serial number 001. Like the SUIT, the pointer inside drops down from above rather than sticking up from below. This is often thought to be a uniquely British design, but in fact it was somewhat common at the time. The standard Colt telescopic sight for the AR-15 has a similar inverted pointer, the theory being that a military user brings his weapon up from a low ready position and so would not wish to have his man-sized (300m distant) target obscured by his own sighting system. There is no provision for iron or backup iron sights.

Finally, a steel 20-round magazine is fitted, necessarily proprietary in design due to the greater overall length of the 4.85x49mm cartridge. The magazine is numbered (“5”) by hand and is painted with a white stripe down the right side, presumably both for recognition purposes during the design process. Again, it would have likely been easier to adopt the AR-18 or AR-15 magazine.

As one might expect, the Light Support Weapon is virtually identical but features a longer, heavier barrel with a bipod and a bulkier handguard design with ventral channels to accept the folded bipod legs. Interestingly, the only mechanical change was to add a reciprocating mass (a tungsten pellet) to the bolt carrier in order to reduce rate of fire and, especially, carrier bounce, which had caused significant problems. This feature later became standard on both the IW and LSW.

The “00 series” feasibility study resulted in a further set of rather vague parameters that might apply to any new small arm. The new weapon should be:

- Lightweight;

- Compact and easily handled; and

- Simple to operate, aim, fire and teach.

- It confirmed that the new weapon system should comprise:

- An Individual Weapon (IW) (a small calibre rifle) to replace the rifle, L1A1 (SLR) and SMG, L2A3 (“Sterling”); and

- A Light Support Weapon (LSW) (specifically a machine gun in the same calibre) to replace the L4A4 (Bren) and ground role L7A2 GPMG.

- Both should be selective fire.

The “0 Series”

This gave the green light to another pre-production series known as the “0 series,” again based upon its serial numbering. These weapons were produced from 1975 to 1976 and represent the second evolutionary step toward the final SA80. The major improvements comprised:

- Revised reinforced receiver architecture.

- Rock in’ magazines with an L-shaped catch relocated to the left side, intended to be operated by the support hand thumb.

- Three-round burst feature deleted.

- Selector switch replaced with a rotary design marked “R” and “A,” similar to the SA80 design.

- Trigger weight reduced from a ridiculous 24 pounds to 8-10 pounds.

- Flash suppressor machined as an integral part of the barrel (to reduce costs) and fitted with an annular ring and spring for grenade launching.

- Rear sling loop on top of the receiver.

- Properly moulded and textured polymer furniture including a cheekpiece glued onto the upper receiver. A bipod mounting point is incorporated into the spring-clip handguard retainer.

- A lengthened sight bracket was fitted to allow for proper eye relief.

- Provision for emergency iron sights; a folding front and a removable rear (the former being kept folded when not in use and the latter stored in a new compartment in the grip).

- A bolt hold-open device activated either automatically by the follower of the empty magazine or manually by a small catch (part of the hold-open bar itself) protruding from the bottom of the lower receiver. This is not a bolt release, however, so the cocking handle must be operated to close the bolt.

The bolt has been reinforced; it is now cut away to only 2/3 of its maximum diameter in order to accommodate the (still quite large) extractor.

The bolt carrier group was standardized for both IW and LSW with a new flat-sided design, including the anti-bounce feature. It also incorporates a guide lug on the rear lower left side. Along with the cam pin, this runs in a special channel welded onto the inside of the upper receiver. Amusingly, the rear of the carrier is now marked “R,” presumably for “rear” to avoid incorrect user insertion!

Some examples of the 0 series were further modified. Their bolt carriers were relieved on both sides with large lightening cuts, and these were marked “FOR TRIALS ONLY.” They also bear a revised design drawing number to reflect this change—all of the experimental weapons in these series have components marked with drawing numbers to keep track of the different build standards and modifications. The “trials” in question must have been those carried out on the 0 series to inform the next iteration of the design (rather than the NATO trials). Finally, it appears that a hinged dust cover was also designed at this time but was not widely fitted (by means of spot welding) until the final iteration of the XL60 pattern (see below).

In addition to all of these changes, the 0 series LSW/MG also received a new cylindrical pattern of pinned-on flash suppressor (which Raw calls a “muzzle brake”) and optional 30-round magazines. A single example of an LSW with detachable barrel was produced, as well as an experimental under-barrel grenade launcher.

The Enfield Weapon System Unveiled

It was at this point, on June 14, 1976, that the new family of weapons was officially revealed to the public and dubbed “Enfield Weapon System” along with a series of official “XL” (for “eXperimental, Land service”) designations. Despite the use of 0 series weapons in promotional photographs, technically speaking, the XL numbers listed at the beginning of this article should apply only to the third and final iteration of the original design that emerged after this date. This series incorporated feedback from the 0 series and efforts at “value engineering” to make the design viable for mass production. These weapons were serial numbered with “B” prefixes for the IW and “J” for the LSW (although with proper XL designations, there is no longer a need to refer to them by their serial ranges). They featured:

- A FAL or AK-style paddle magazine catch replaced the AR-18 style rocker switch/button, with matching changes to the magazine design.

- A new lever-type safety catch on the left side (regardless of left- or right-handed variants).

- Redesigned bolt carrier patterns specific to IW and LSW variants (see below).

- Further revised polymer furniture with more texturing. The new handguard dispensed with the bipod attachment point, replacing it with a simple D-ring sling swivel and, for the first time, featured a proper sheet metal heat-shield.

- A revised butt-plate with optional extended butt-plates to vary length of pull (this made the longer sight bracket redundant). The sling loop reverted to the bottom only.

- 30-round magazines were now standard (but notably, not yet STANAG standard).

As before, the LSW variant differed primarily in its heavy barrel and bipod and was claimed to possess 80% parts commonality with the IW. However, the handguard, gas plug, safety sear (auto sear), change lever and, importantly, the bolt carrier were all of different patterns. Both BCGs featured a flat outer side, but the rifle pattern had a deep lightening scallop in the outer face, and the LSW version instead had a groove machined into its inner side (above the cam pin and guide lug, aside from a single exception where a rifle pattern BCG was originally fitted to an LSW but later installed in a rifle and re-serialized). This groove appears to simply give greater clearance for the bolt carrier and prevent it from rubbing against the internal cam pin rail, presumably to improve open bolt functioning. A new bipod was designed, this time with sliding adjustable legs, and the pinned LSW-specific flash suppressor was reverted to the previous pattern (as on the IW barrel).

The new XL64E5 and XL65E4 offered improved ergonomics thanks to the new pattern safety and magazine catches. The non-ambidextrous safety lever is actually easier to operate for left-handed shooters, who are able to use the index finger of the firing hand to sweep it up and down. Right-handed shooters need long thumbs or are obliged to break their strong-hand grip. As ARES writer Ian McCollum notes, however, the safety is rather large and easy to operate inadvertently, especially with left-handed guns/users. The change lever (selector switch) carried over from the 0 series design is adequate but, like many XL64/5 components, is a complex shape that would later be simplified.

Reliability Issues

It was this build standard that was used in the problematic NATO ammunition trials. These both revealed reliability issues with the weapon design in its prototype form and buried the idea of a British 4.85mm cartridge. The biggest issues were with the trigger mechanism, namely:

- Weapon firing auto when set to single shot; and

- Trigger not returning to the fully forward position when released.

These issues were blamed on ingress of dirt and other foreign material (although two other “runaway gun” issues were identified with 0 series guns that were unrelated to this cause). Examining a trigger mechanism housing today, it is easy to see why the very tight fit of parts might result in problems of this nature. The weapons also suffered feed problems, notably a failure to eject. There were also problems with poor welding and weak and out-of-spec components. The biggest early issue was with barrel wear; the 4.85mm EWS barrel provided a service life of only 3,000 rounds, compared to 20,000 for the AR-15. This seems to have been solved by (or at least by the time of) the shift to 5.56x45mm. None of this—with the possible exception of the excessive barrel wear—is surprising for a new design and could no doubt have been solved given sufficient available expertise, resources and time.

The final iteration of the XL60 family was in many respects a promising, compact and lightweight design that reflected the cutting edge thinking of the day. Enfield made a good choice in borrowing from ArmaLite’s AR-18, and they broke no laws and infringed no patents by doing so, just as many other manufacturers continue to make liberal use of the successful features of earlier rifles in their modern designs. These features were a sound basis for a modern combat rifle, and Enfield’s design could have been a successful bullpup derivative of that weapon. However, as we shall see, the path to the truly capable SA80A2 series was to be a long and difficult one.

[Editor’s Note: In the Second World War period it appears that “R” officially stood for “Rounds.” This potentially confusing term was replaced by the more specific “Repetition” from the EWS pamphlet onwards.]

••••••••••••••••••••••••

Special thanks to the National Firearms Centre at the Royal Armouries, who graciously allowed us access to their world-class collection, and to the Defence Academy of the United Kingdom at Shrivenham, for allowing us to handle and fire an EWS rifle. Thanks are also due to Neil Grant.

See armamentresearch.com for further original content.

(This article is adapted from a chapter in Mr. Ferguson’s forthcoming book on British bullpup rifles, which will be published by Headstamp Publishing in 2019. HeadstampPublishing.com)

| This article first appeared in Small Arms Review V23N3 (March 2019) |