By Frank Iannamico and Chris Cox

Part II – Harrington and Richardson

During the early days of U.S. military involvement in Vietnam, U.S. advisors were issued M1 and M2 carbines. When the first Marines arrived in 1965, they were armed with M14 rifles, as were most U.S. Army personnel. It was soon realized the 7.62mm M14 rifles were too powerful and unwieldy for the type of hit and run engagements being encountered with the enemy. The enemy was often equipped with AK rifles with 30-round magazines, a select-fire capability, and mid-range 7.62x39mm cartridges that allowed them to carry a larger ammunition load than U.S. troops. The M14 rifles had 20-round magazines, long-range 7.62x51mm ammunition, and most of the rifles were fitted with selector locks limiting their operation to semi-automatic-only. A lighter weapon with controllable automatic fire was needed to match the enemy’s AK rifles; enter the M16. Despite the M16 rifle’s controversial early problems with malfunctions, most of the shortcomings were addressed with the M16A1 model.

After the introduction of the M16A1 rifle, the conflict in Vietnam continued to escalate. The Army needed more rifles for both U.S. troops and to replace the World War II weapons being used by the South Vietnamese and Korean allies. During this period Colt was the only company producing the M16A1 rifle. The Department of Defense wanted to have a second source to manufacture the rifle. Unlike the M1 Garand and M14 rifles that were developed at the U.S. Springfield Armory and manufactured by several commercial companies, Colt owned the exclusive rights to the AR15/M16 design and were reluctant to release them to the government. Finally, in June of 1967, after years of negotiations an agreement was reached allowing the government to seek bids for second source production. The two manufacturers awarded contracts were the Hydra-Matic Division of General Motors and Harrington and Richardson (H&R). Estimated ceiling prices with non-reoccurring startup costs were: first year production of 60,000 rifles at $250.00 each, second-year production 180,000 rifles at $150.00 each. The prices did not include the reoccurring cost of $8.68 for seven magazines, or the $4,500,000 and 5.5% royalty paid to Colt for the rights to establish a second source production. The establishment of second source for M16 production was not considered to be economically justified unless H&R was at least 33% below the established ceiling price. Colt’s 1963 M16 contract was priced at $126.37 per rifle, the price was reduced to $104.39, each, by September 1967.

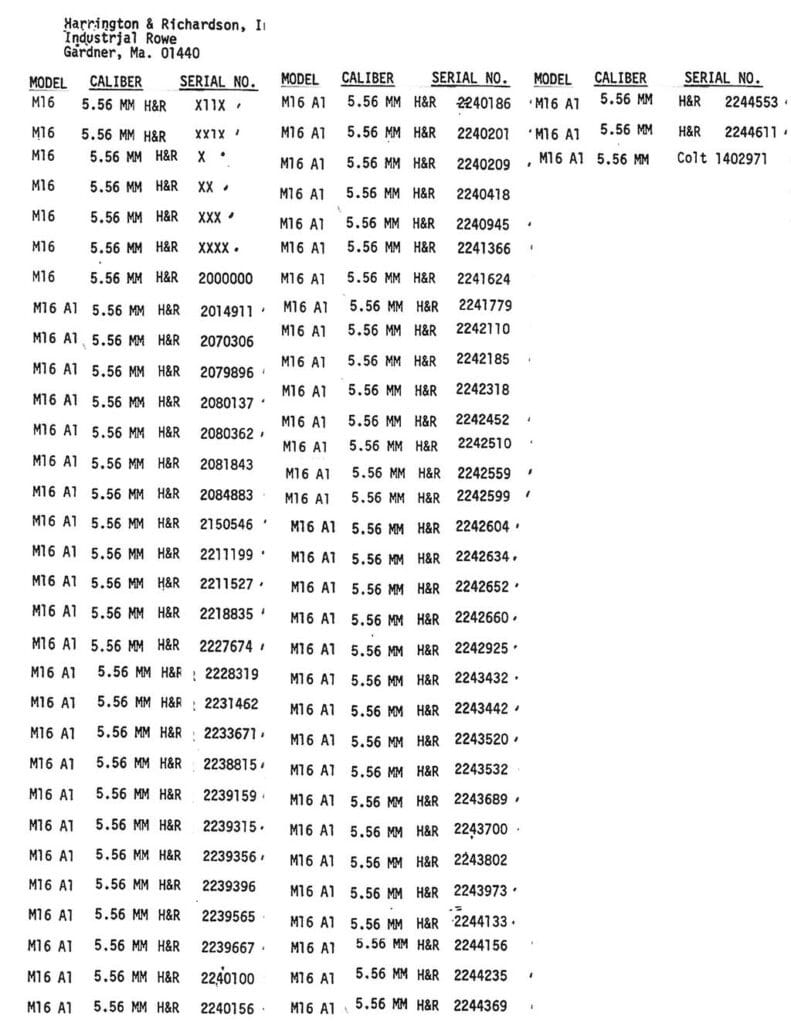

H&R’s contract was DAF03-68-C-0045 dated 19 April 1968 for 240,000 rifles at a cost of $170.43 each. The first delivery was made in December of 1968, the final delivery was made March 1971. All H&R M16A1 rifles were assigned serial numbers in the 2,000,000 range.

Harrington & Richardson Inc. was a well-established U.S. firearms manufacturer. It had previously manufactured weapons under contract for the U.S. Government, that included the M1 Garand during the Korean War and M14 rifles during the 1960s, as well as the Reising submachine gun that saw limited use in World War II. Harrington and Richardson operated three factories located in Gardner, Worcester, and Rochdale, Massachusetts, and a fourth plant in Elm Grove, West Virginia. After H&R’s 1968 M16A1 contract ended in 1971, all the facilities were closed except the Gardner factory at 60 Industrial Rowe. Phillips Metallurgical, Inc. was a subsidiary of Harrington and Richardson, located in Swanton, Vermont. The company was a foundry which supplied H&R and other companies.

“Is that a handle?”

Today, the AR15 type rifles are unrecognizable from those made in the 1960-80 era. Gone from the rifles are the carry handle upper receivers, fixed buttstocks, and triangle handguards; replaced by multiple rails for attaching optics, lasers, red-dot optics and flashlights. Many younger AR enthusiasts are not familiar with the rifles in the original configuration. Often when seeing an early manufacture AR15/M16 they will ask “What is that a handle?” referring to the upper receiver. The AR15/M16 was designed to keep the recoiling parts in-line with the buttstock to reduce muzzle rise in full-automatic fire. As a result, the sights of the rifle had to be elevated. The original carry handle of the M16’s upper receiver was used to mount the rear sight, keeping it in line with the raised front sight. Today’s AR15/M16 rifle has come a long way since it first appeared in the jungles of Vietnam.

After a controversial and dubious start, the AR type rifle is now one of the most popular semi-automatic civilian firearms in the U.S. With the widespread use of modern optics, the carry handle was removed from the design and replaced with a rail. There was a period where no commercial manufacturer offered an AR model with a carry handle, and soon the existence of the handle was forgotten or unknown.

The upper receivers on most H&R M16A1 rifles have forging flash seams on both the front and rear of the carry handle.

Retro M16A1 Rifles

Despite the modernization of the AR15/M16 rifles since its introduction more than 60 years ago, there is a growing interest in the original “old school” configuration. Many retro aficionados are building clones, albeit semi-automatic, of the Vietnam era M16 rifles. Many purists seek original parts to assemble their guns, although most must settle for a modern lower receiver. Original style receiver markings are available from several companies that offer laser engraving, yet another offers markings applied by the original roll-marking method. Most available lower receivers offered today are the reinforced M16A2 pattern, introduced during the 1980s, while all the Vietnam era receivers were the M16 or M16A1 type. Since M16A1 forgings aren’t produced any longer, reinforced A2 style forgings must be carefully machined to the original A1 specs.

Identifying Harrington and Richardson Parts

Note: There are certain features that are common to most H&R manufactured M16A1 rifles; with the small fraction of the weapons available for examination, it is not possible to make definitive statements regarding component identification. Arsenal rebuilding and repair of weapons in the field by armorers, and the large number of subcontractors supplying parts make positive identification impossible.

It is quite likely that many subcontractors were used by H&R during the production of their M16A1 rifles, for example H&R in their M14 production subcontracted out 89 of the 110 parts used in an M14 rifle using 37 different companies.

There are several ways to ID most H&R parts from those from GM / Hydra-Matic and the far more common Colt parts. Many H&R parts were marked with a number, most likely to identify the subcontractor. It’s quite possible they may have used a few of the same subcontractors as GM/Hydra-Matic for some M16A1 parts, as similar markings have been noted on parts on rifles from both manufacturers.

Lower Receiver

The color of the anodizing on H&R contract M16A1 rifles varies; many are darker in color than Colt’s 1960s era gray. The left side of the magazine well is roll marked with H&R’s Lion trademark enclosed in a circle and Property of U.S. Gov’t markings. The right side of the magazine well has a full “fence” around the magazine release. Often the right side was marked with a white Department of Defense eagle acceptance stamp. The acceptance stamp most often seen on H&R rifles is 0.5-inch and similar to those found on Colt rifles of the same era.

Upper Receiver

There are variations of the upper receivers documented, one common sign is the lack of markings in the concave area on the right side under the rear sight. Post 1970 Colt contract upper receivers will have two letters in that area. H&R upper receivers will generally have a forging flash, or “seam” on the front or rear of the carry handle. GM/Hydra-Matic upper receivers typically have the forging flash on the rear portion of the handle. The forward assist may or may not have a number on the back side of the teardrop handle. The ejection port door had a small pad with rounded corners.

Charging Handle

The profile is usually thicker than those fitted on GM and Colt M16A1 rifles, but there have been no distinguishing marks noted.

Fire Control Group

The fire control components, hammer, trigger, and the fire selector lever will have a number and/or a letter H on them. The disconnector was not marked. The mode of fire selector lever will have a number on the back surface. Keep in mind that using M16A1 fire control group parts in a semi-automatic AR rifle can cause legal problems. It is strongly suggested that any M16 internal parts be altered to a semi-automatic configuration.

Barrel

H&R barrels will generally have the letters MP upside down on the left side between the legs of the front sight base. There will be a letter C on the top of their barrels, just aft of the muzzle, indicating a chrome chamber. Barrels are the 0.625-inch outside diameter “pencil” type with a 1:12 twist, and a birdcage flash hider. Original barrels are probably the most difficult component to find, as many M16 rifles had to be re-barreled due to excessive use, and / or corrosion of the non-chromed bores. Colt and other contractors made thousands of replacement barrels during the Vietnam War.

Front Sight Base

There are several front sight base variations. Some have forging flash on the front and/or rear, and on the bayonet lug. Some bases observed had a letter or number on the sides.

Furniture

Most were fitted with type D buttstocks with a rubber buttplate without a trapdoor, and have an articulating sling swivel. The furniture will often have an aged, mottled appearance. The pistol grips were slightly larger in circumference than those on Colt M16A1 rifles.

H&R pistol grips, handguards and buttstocks will be marked with letters and/or numbers observed in various locations.

Bolt Carrier and Bolt

H&R bolt carriers do not have any manufacturer’s markings; the finish machining appears rougher than on Colt carriers. H&R bolts were marked MP to indicate that they were magnetic particle inspected. The marking placement is different than Colt/GM and runs front to back.

Bolt Stop

H&R bolt stops have a subcontractor ID number on the bottom. Numbers 1 through 7 have been noted.

On December 3, 1984, Harrington and Richardson of Gardner Massachusetts filed for Chapter 11 reorganization under federal bankruptcy laws. In a press release, C. Edward Rowe Jr., the company president, said the company was forced to seek reorganization because of declining business and a major product liability claim in Pennsylvania. In addition to the Pennsylvania claim, Mr. Rowe estimated there were 12 additional product liability cases pending against the company. In November 1985, it was revealed that there were several parties interested in purchasing Harrington and Richardson and its subsidiary Philips Metallurgical Inc.

During December Harrington and Richardson was granted permission by the U.S. Bankruptcy Court in Worcester, Mass. to continue operating under a current plan of asset reduction until a new hearing was scheduled. The asset reduction plan was estimated to generate one-million dollars. H&R’s attorney John Sigel said the asset reduction plan generated more funds than the company had expected.

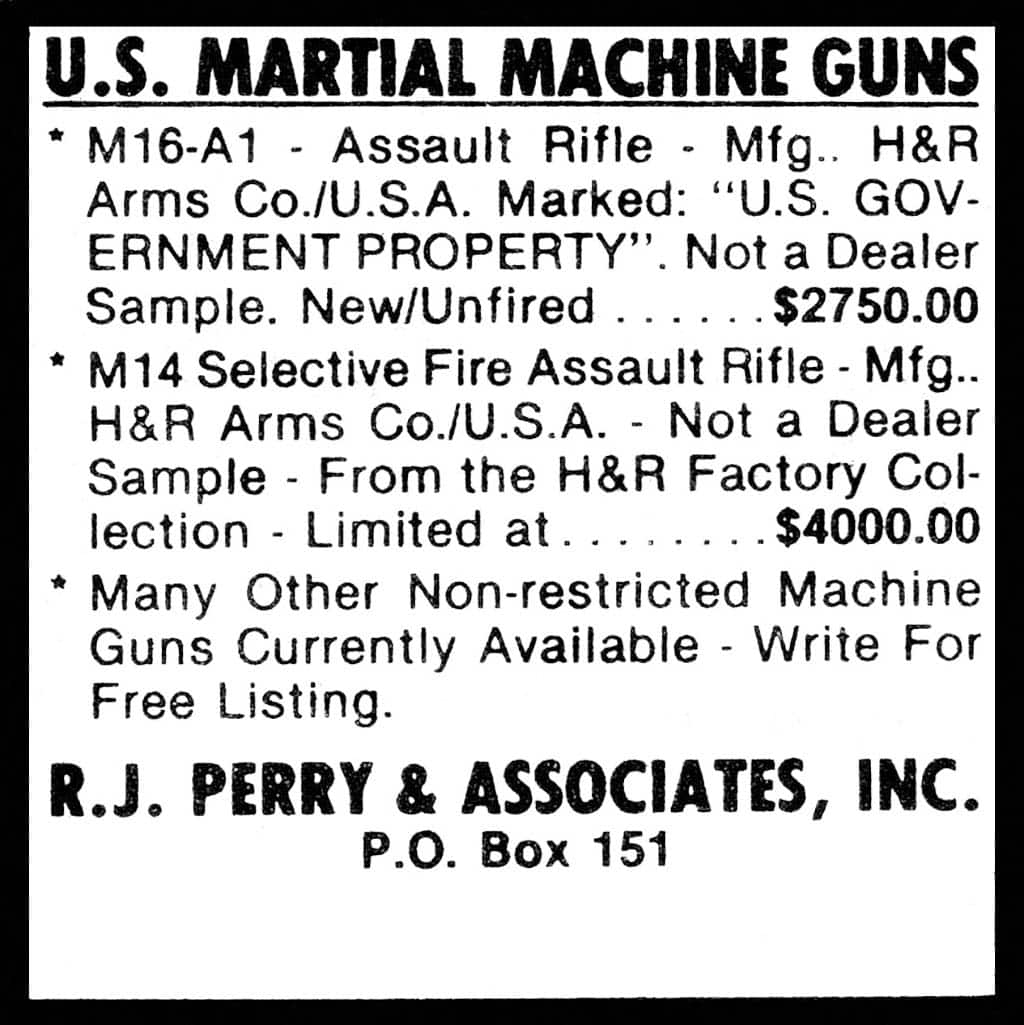

Despite the smaller numbers produced, H&R M16A1 rifles are more commonly encountered than those made by GM / Hydra-Matic. There were a number of small arms sold during H&R’s asset reduction sale (despite popular belief, there was not a bankruptcy auction). A large lot of the weapons, which included 29 M14s, 65 H&R M16A1 rifles and 1 Colt M16A1, were purchased by “John K” a somewhat mysterious individual from eastern Pennsylvania. The M14 and M16 rifles were transferable and sold at, what seems like today, bargain basement prices.

By the fall of 1986, a new buyer was found for the Harrington and Richardson company, Vincent Sheil Incorporated. Paul A. Senecal, an investor in Vincent Sheil Inc, and former Director of sales and marketing at Harrington and Richardson, said the new company would continue to manufacture firearms. A $1.5 million offer was made for H&R’s assets including equipment and machinery, and the assets of the Phillips Metallurgical Inc. foundry. The new company was to operate under the name New England Arms. The agreement allowed the new firm to lease the 60 Industrial Rowe property. On December 20, 1986, the sale was approved by the U.S. Bankruptcy Court. The sale of Harrington and Richardson to Vincent Sheil Inc. saved jobs, kept the company’s assets from being liquidated at auction, and the factory sitting vacant.

H&R M16A1 Rifles examined

- 2243700

- 2074531

- 2339159

- 2081621

- 2080362

- 2122678

Resources

- AR-15.com

- Government Documents (Declassified)

- Procurement, Production and Distribution of the AR15, M16 and M16A1 Weapon System (1 June 1968)

- Procurement History and Analysis of the M16 Rifle AMSWE-PPE-72-01 (printed 2 August 1971)

- M16A1 Initial Production and Comparison Test; GM. H&R, Colt. (9 Jan 69)

Books

- The Black Rifle-M16 Retrospective R. Blake Stevens and Edward C. Ezell

- The Great Rifle Controversy Edward Clinton Ezell

- The Last Steel Warrior, the U.S. M14 Rifle F. Iannamico

Special thanks to: Eve Eisenbise, Anthony Ciravolo, and Jeff Bodell. (ATF FATD), John Scott, David Gilmore, Alex McKenzie, Springfield Armory Historical Site

This article first appeared in Small Arms Review V25N10 (December 2021)