By Christopher R. Bartocci

Debuting in 1982, Glock has revolutionized the foundation on which military and law enforcement handguns sit. Glock pistols not only revolutionized the material in which military grade pistols are manufactured but the sheer market share they hold is nothing short of amazing. Entering the market as a polymer frame firearm with the fewest parts of any firearm of its kind with utter reliability and dependability, Glock converted the most diehard steel and aluminium frame pistol shooters into devout disciples of polymer. In the early days the pistol was very disrespectfully referred to as “Tactical Tupperware” due to the type of box in came in as well as the occasional joke of the gun coming with a tube of epoxy for repairs would soon lead all detractors into the world of Glock.

Generation 1

The first generation Glock 17 pistols had a smooth polymer grip. They had a 2-piece spring guide and recoil spring. The magazine was designed so it would not drop free when the magazine release was pressed. Although this proved to be problematic for American users, the Austrian Army required it. Rumour had it that it was so the magazines could not be lost in the snow. To be able to import the gun into the United States a few modifications had to be made. In Europe the serial number had to be on the slide and barrel. In the U.S. it is required on the frame, so Glock moulded a tab into the frame. Also to meet the points for importation, Glock added an adjustable sight. The first generation was in fact the Austrian Army model P-80 although it would be sold else where as the Glock 17 (Gaston Glock’s 17th patent).

The Glock 17 pistol is striker fired omitting any external hammer. The striker has a partial load on it when the pistol is ready to fire. Approximately 25% of the load is taken up. When the trigger is pulled, the remaining 75% of the striker is taken up and released to fire the cartridge. Mr. Glock called his pistol “Safe Action.” No external safeties are used. However, the pistol has 3 internal safeties. To gain a realistic perspective, you must understand that military and law enforcement personnel carried revolvers with no manual safety for many years. This was never deemed unsafe. However, with double action semiautomatic pistols, it is common for firearms instructors to find it difficult to train inexperienced people. Reason being the first heavy pull of the trigger is often a flyer due to the extreme amount of force required to depress the trigger. The follow-up single action shot is often also a flyer due to anticipation of the heavier trigger pull, even though the pistol is now firing in the lighter single action mode. The Glock pistols have one constant trigger pull from first to last shot. Removing the element of anticipation, the shooter has enhanced accuracy and more accurate first shot hits.

The 3 safeties in the “Safe Action” Glock pistol are all passive and function in order. The first safety is the trigger safety. There is a lever in the center of the trigger that unless disengaged prevents any rearward movement of the trigger. The trigger safety is disengaged only by the trigger finger. The second safety is the firing pin safety. The firing pin safety physically blocks the strikers’ movement until the trigger is pulled to the rear. When the trigger is pulled rearward, the trigger bar pushes upward on the firing pin safety disengaging it. The final safety is the drop safety. This is a track which the trigger bar/cruciform moves. When the trigger is pulled all the way to the rear the trigger bar is pushed down, releasing the striker to fire the cartridge. When the trigger is released, all 3 safeties automatically engage. The Glock pistol has been dropped 100 feet in the air from a helicopter with a primed cartridge in the chamber. When examined, it did not fire.

The slide is manufactured from a bar of solid steel and is finished by a process called gas nitration. This clear finish penetrates .05 inches into the metal. The slide of a Glock pistol is so hard it is just under a diamond on the Rockwell scale (55 to 60). This finish is so hard that Austrian soldiers sharpen their bayonets on the slide. This finish is corrosive resistant as well.

The barrel of the Glock 17 is cold hammer forged. After a pilot hole is drilled through the center of the barrel a mandrel, which contains the rifling and chamber, is placed inside the barrel blank. Multiple hammers exert tons of force on the outside of the barrel, forming the polygonal bore and chamber. Unlike conventional barrels with cut rifling, there are no sharp lands and grooves. The bore diameter is tighter than a conventional barrel as well. This does two things. First, due to no sharp lands and grooves the barrel does not wear much at all increasing long term accuracy/barrel life and making the barrel easy to clean. Second is a tighter bullet to barrel seal increasing velocity.

Generation 2

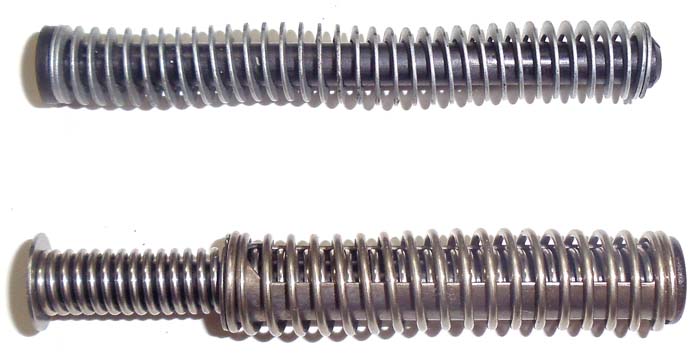

The second generation Glock was made for the desires of the American consumer. First, the grip was changed to add checkering to the front and back strap of the pistol. Additionally slightly rougher sides were added as well. Internally, the recoil spring and spring guide were changed to a captive assembly. Later second generations received an upgrade on the trigger group and firing pin block for improved safety. Glock provided this for free based on the serial number range of the pistol. The pistol was offered with fixed sights, adjustable as well as tritium night sights. Perhaps the most significant change was for the American consumer with the drop free magazine. The internal metal body went around all sides of the magazine preventing the magazines from swelling whether empty or full. With the introduction of other calibers, an additional pin was added to secure in the locking block on all non 9×19 caliber pistols. During this generation calibres in .40, 10mm Auto, .45 Auto, .357 and .380 Auto were introduced.

Generation 3

The third generation pistols brought the Glock into the accessories era in the late 1990s time frame. First is the addition of a rail on the front of the pistol for adding tactical lights as well as laser sights. In 2003, Glock introduced with this pistol a trio of light options. First a tactical light only, then a tactical light/laser sight combo and then a tactical light/visible laser/IR laser combo. Added to the front of the frame are 3 finger grooves and thumb swells on both sides of the receivers. Some pistols were also sold with the Glock extended slide release. The color of the finish would change as well to a more glossy black finish. The long awaited addition of a loaded chamber indicator was introduced as well. This enabled the shooter to run his finger over the extractor. If it was felt it was most probably loaded, if not it was unloaded. Through the beginning of this generation of pistols Glock still used separate frames for 9×19 pistols, later in the Generation 3 all would be switched to the same frame with the extra pin for the locking block. Additionally the frames themselves were strengthened. This came around the development of the .357 cartridge. This caliber required a stronger frame than the Generation 2 so this was built into the Generation 3. If you had a .40 caliber pistol with a Generation 3 frame you could swap out the barrel for a .357 and fire it safely. It was not in the case of the older G22 frame. This Generation would see the introduction of the G35, and G36 as well as in 2002 Glock introduced their internal gun lock requiring a Glock key to engage and disengage.

In 2004, the .45 G.A.P. round came into play in model G37 and in 2005 in the G38 and G39. This is the first cartridge introduced by Glock. Clearly over the past several years, law enforcement trends show a shift back to the .45 Auto calibre cartridge. With this switch, many smaller statured officers have had great difficulty using full sized .45 Auto caliber pistols. Glock engineers took a long look at the 100 year old cartridge and found that there are several changes that could be made to make the cartridge that much more efficient. First the cartridge case was longer than needed with modern propellants. There is a significant amount of wasted space in the powder cup. So the cartridge case was shortened taking advantage of modern propellant. It was found that when firing the same weight bullet the .45 G.A.P. or .45 Glock Automatic Pistol would fire at slightly higher velocities than the legacy .45 Auto. The profile of the bullet was changed decreasing the length of the projectile. Now Glock had a .45 Auto-type bullet in a much shorter package that now could be placed in a 9×19/.40 caliber frame. Officers with smaller hand would have little difficulty with the .45 caliber handgun when using the 45 GAP cartridge.

In 2007, Glock introduce its first SF (Short Frame) pistol the G21 SF. This is a full size Glock 21 .45 Auto caliber pistol with 2 distinct changes. The pistol has a new, sleeker lower receiver with an ambidextrous magazine release button. This required a new magazine. The change was the engagement surface of the magazine catch is on the front of the pistol grip so it had to be on the front of the magazine. Standard G21 magazines will not work. However the G21 SF magazine will work in all other Glock 21 and 30 pistols.

In 2009, Glock introduced their new RTF2 (Rough Textured Frame) pistol. The grip has been the most evolving change throughout the evolution of the Glock pistol. The new RTF2 consists of hundreds of miniature “polymids” on the front, rear and sides including the thumb rest resulting in increased traction.

The Generation 4 Glock

Mr. Glock has as his corporate motto “Glock Perfection,” and there is no question he means it. He understood that to maintain that perfection he would have to always improve his weapon. Though mechanically this is a sound weapon, probably the most durable handgun in history, the evolution would have to continue in order to stay as the number one handgun in the world. The changes that would need to be made were more cosmetic and having the pistol adapt to different shooters hands as well as styles. Glock’s Generation 4 pistols were introduced in 2010.

Shooter’s hands as we all know come in all sizes and it is difficult to make one firearm that will suit all. This is the particular case in a Law Enforcement and a military pistol. You will have the smallest hands of a female officer to the Sasquatch size hands of this author. Trends within the industry were to have removable backstraps that would adjust the grip size for the individual shooter. In true Glock fashion, they responded to the customer and offered the Generation 4 pistol with two backstraps. The frame with nothing is for the smallest hands, there are a medium and a large backstrap. Also in true Glock fashion it is simple to install. The pistol is supplied with a simple punch which pushes out the trigger housing pin, the backstrap snaps in place and the trigger housing pin is replaced. Additionally, the texture of the grip sides and the finger grooves were changed to a better and more grippable square pattern.

A major change was the magazine release of the pistol: it is reversible and the button is significantly larger. In order to make the magazine catch reversible, the magazine was modified so that the engagement notch for the magazine catch is on both sides. It means if you want to move the mag catch to the right side you have to have a new production Gen 4 magazine. If you leave it on the left side you may use any generation magazine.

The mechanical improvement came in the form of a new spring guide assembly. Although the Glock pistol is very light compared to most of its kind, the recoil is very manageable and mild. Glock pistols have always used the strongest and longest lasting flat recoil springs. With the introduction of the mini Glock pistol (G26, G27, G28, G29, G30 and G33) in 1996, a new recoil spring was devised. Dual springs were used softening the recoil and the impact on the frame making the pistols extremely mild in the area of recoil. Glock applied that technology to the larger frame pistols introducing it in the Generation 4 G17 and G22. This required modifications to the slide to accept the larger end of the recoil spring. When comparing a generation 3 and 4 on the range it is clearly evident which is which. The push and flip of the generation 4 is noticeably less assisting in even quicker follow-up shots.

The Generation 4 pistol was released at the 2010 SHOT Show and was accepted with open arms. Soon to follow were the compact and mini pistols. The ones still not converted over are the larger frame G20, G21, G29 and G30 pistols which the G21 GEN 4 is anxiously anticipated by this author. Glock Austria showed prototypes of the G21 Gen 4 at the IWA show in Nuremburg, Germany in February of 2011. This author looks forward to the G21 Gen 4 in 2012.

| This article first appeared in Small Arms Review V16N2 (June 2012) |