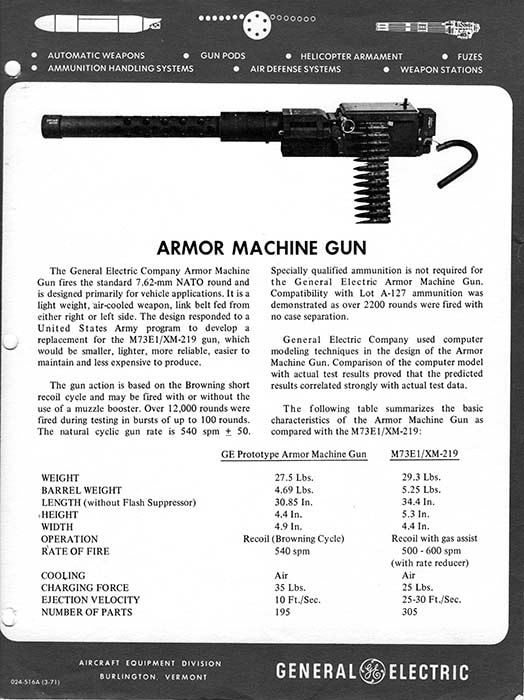

GE-Developed General Purpose 7.62mm Armor Machine Gun (Author’s Collection)

By George E. Kontis, P.E.

I had started a new job with Ajaxx Gun Works and was meeting with the Engineering Director to discuss my first assignment. Based on my past experience as a product engineer, the Director entrusted me with a project to find the cause and correction for malfunctions on a new automatic rifle that were occurring during automatic fire.

Two firearms technicians had been assigned to work under my direction. The Director asked me to proceed to the range immediately as the technicians would have the guns and the test equipment ready. “Are these two guys any good?” I asked him. “Beener has been with Ajaxx nine years and Chumwell has been here twenty two. Chumwell is the steward of the technician’s union,” he responded. “They both have done a lot of testing. Chumwell has an excellent attendance record. He only missed work when he blew the end of his finger off during a test. He put his finger over an open pressure transducer hole in a cannon barrel. Chumwell noticed he had forgotten to put the transducer in and decided he could plug it with his finger. He’s learned a lot since then.” That really wasn’t the answer I was looking for, but it did speak volumes. I let it all go as I was eager to begin the tests.

At the test site I found only one technician and introduced myself to Chumwell. When I inquired the whereabouts of Beener I learned that he went to get fans. Silently I told myself that fans might be a good idea to cool the guns and move the testing along more quickly. On the table was a stack of guns thrown together in a heap. Nearby was a pile of linked ammunition. “This can’t be our ammo– it’s linked.” I said. “These guns need loose ammo and delinking it will take a lot of our time.” Chumwell said somebody had forgotten to replenish their ammunition supply, but not to worry, because a couple of technicians who normally clean guns would be sent out to delink ammunition for us. “We’ll have to wait for them because we don’t delink ammo.” Chumwell announced. “It’s not in our job description.”

Finally Beener arrived with the fans and it was only then I learned that the fans were not for the guns, they were brought out so my two test technicians didn’t get hot while shooting. Poor dears! Beener switched on the three fans, acoustically transforming our quiet test site to the likes of an active airport runway. I watched as papers, cups, and other small items flew everywhere, and decided to keep my hearing protection on for the duration of the test.

I called Chumwell and Beener over for a meeting so I could outline the tests I wanted to have performed. When I got to the part where I talked about re-lubing the guns, Beener informed me that they didn’t have gun lube at the test site. They never bring it out because, in their opinion, the guns seem to have plenty lube when they come out of the gun cleaning department. Beener was noticeably unhappy when I informed him he would be making a trip back to the factory for lubricant, just as soon as our meeting was over.

It was close to noon by the time Beener arrived with gun lube and the gun cleaners had finished delinking our ammo. Over Chumwell’s objection that it was too close to their lunch hour, I insisted that we begin testing. Not long into the test cycle we encountered our first malfunction. I examined both the gun and the damaged fired case. The ejection port was supposed to be lengthened on this gun. I wondered if that operation could have been missed by the prototype shop. It was easy enough to check. I reached in my pocket for a scale and moved it in the direction of the ejection port. I was surprised to find Chumwell’s hand suddenly blocking mine. “If you want something measured, we’ll do it. We’re the engineering technicians,” he said. When I voiced my disapproval, Chumwell got testier. “If you decide to measure it on your own, I’ll file a union grievance.” Oddly, I found myself thinking about my grandmother. “You can tell if it’s going to be a good day by the way it starts,” she always said. If true, this was going to be a very long day and I was beginning to have my doubts about Ajaxx.

As the testing continued and the number of malfunctions mounted, I was curious as to how many stoppages we’d encountered. I asked Chumwell to hand me the test firing log so I could count them. Chumwell informed me there was no log. Yelling over the din of the three fans, he said: “See these marks here on the table?” He pointed to a series of vertical lines grouped in a series of four with a crossed line indicating the fifth. There were two like this and a single as well. The marks indicated we’d had eleven malfunctions. “We keep track with them this way. We also know how many rounds we bought out and how many we turn back in. That gives us our round count,” he announced proudly. “Hey, what more do you need to know?” I thought about mentioning that some of the malfunctions were failures to extract while others were short recoil failures. Their system didn’t account for the difference, but at this stage I decided it was pointless.

In the next round of tests, a part failed. I asked them to replace it so we could continue. “There are no spares out here,” came the reply from one of them. “It’s too much trouble to bring them out.” During the long wait for the replacement part to arrive from the plant, I noticed a screw had loosened on one of the guns. I pointed it out to Beener and asked him to tighten it. Moving faster than he had all day, he reached into a leather pouch on his belt and proudly drew out a multi-purpose tool. I stopped him. “Don’t we have any screwdrivers?” “Oh, we can do whatever we need with these,” Beener responded, smiling as he proudly pointed out the many features of the tool. I’d had enough. I walked over to each fan, turned it off and motioned to the two technicians in for a discussion. “The next time you guys run a test for me, I want to see a toolbox filled with real tools and a bottle of gun lube. I’m also going to draw up a sample range test log, and I want you two to keep a record of every round fired and every malfunction.” Beener and Chumwell were not happy, but I didn’t care. I found myself rethinking the wisdom of my decision to sign up with the Ajaxx Gun Works.

Now it’s time for a confession. I never worked for Ajaxx Gun Works and as far as I know, a company with that name has never existed. I have never worked with technicians named Beener or Chumwell either. The events related, however, are based on actual events that either happened to me or they were told to me by other engineers in our industry.

I told this tale to illustrate an important point. A good engineering technician is essential to the development and production of every firearm. In every place I’ve worked, I have been fortunate to have worked with outstanding technicians. There were, however, a very few who made the job more demanding.

I measure the performance of every firearms technician against the one who stood out above the rest. Bill Frigon received his training at the U.S. Government’s Springfield Armory and went to work for the General Electric Company, Armament Systems Division after the Armory closed in 1968. He was an amazing engineering technician.

Bill was assigned to work with me in the development of a 7.62mm General Purpose Armor Machine Gun (called GPAM and later designated AMG). The Army had funded GE, Hughes, Maremont and others, to develop a coaxial machine gun for the M1 Tank. The Army realized they had made a huge mistake by introducing the Springfield Armory designed M73—which they later called the M219.

Before we took the AMG to the firing range for the first time, Bill asked if he could spend some time in the drafting/design office. I was curious as to the reason for this unusual request and was quite pleased to learn that Bill wanted to go through the weapon cycle with the designers. He wanted to look at the individual piece part drawings to see how they were dimensioned and to see what materials and surface treatments were used. A few days later, I was less happy when Bill informed me he was not yet ready to go to the range. I reminded him he had already spent quite a lot of time up in the drafting department and down in the engineering lab. Now what was he doing?

Bill invited me to visit him in his work area so he could better explain. There he proudly showed me a large pile of compartmentalized plastic boxes filled with parts. He had labeled each compartment with the name and part number of each of the spare parts we’d built to support our testing. Bill also showed me a chart he’d constructed. With the drafting room’s help, he had developed a table of events for the gun cycle. Where did the feed stroke begin? Where did it end? What was the location of the barrel extension when the bolt began its acceleration to the rear? Significant events such as these were all indicated on Bill’s chart. Still somewhat a novice in the gun business myself, I didn’t fully appreciate why Bill was taking these great pains for a table of events. None of the other GE technicians ever did this. Bill told me he needed one more day to organize his tools and spares and he’d be ready to test.

We were joined at the firing range by Larry Brainard, a talented instrumentation technician. For our tests, Larry was testing out a new data collection system that used large reels of magnetic recording tape to store data. Larry had set up the system to record inputs from two transducers that were mounted to the gun bolt. One transducer would tell us the position of the bolt and the other would tell us bolt velocity during the time the bolt was cycling. Also new, was an ink pen plotter that printed out the data for us right at the test site.

After a few days of testing, I realized how valuable Bill was to our program. Each day before the testing started, Bill would review our results from the day before, present data and show trends that helped us decide what tests we would run that day. There was never a want at the test site. Spares, tools, lubrication, and cleaning equipment were always on hand, thanks to Bill. Bill requested that he be the only one to maintain the firing records. On these, he kept a meticulous accounting of the rounds loaded, rounds fired, and malfunctions that occurred. When there was a malfunction, Bill made careful note of where in the cycle it had occurred. He marked the fired case or the round damaged by the malfunction with the round number for later examination.

Sometimes a part needed a minor modification—a small chamfer or a surface polished, for example. It was something we could do right at the range without returning to the factory. Whatever modification was done, Bill gave a complete explanation right in firing log. He often added a sketch to explain the change so that if it was determined to be helpful, it could be added to the drawing in order that future parts could be properly modified using the machine tools at the factory.

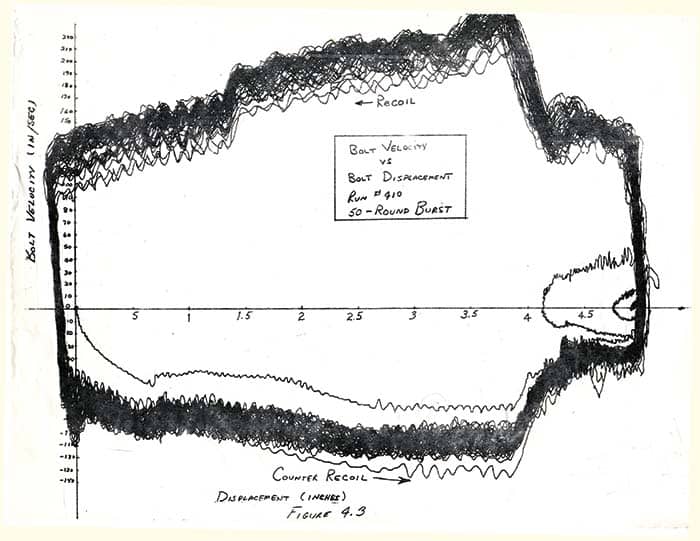

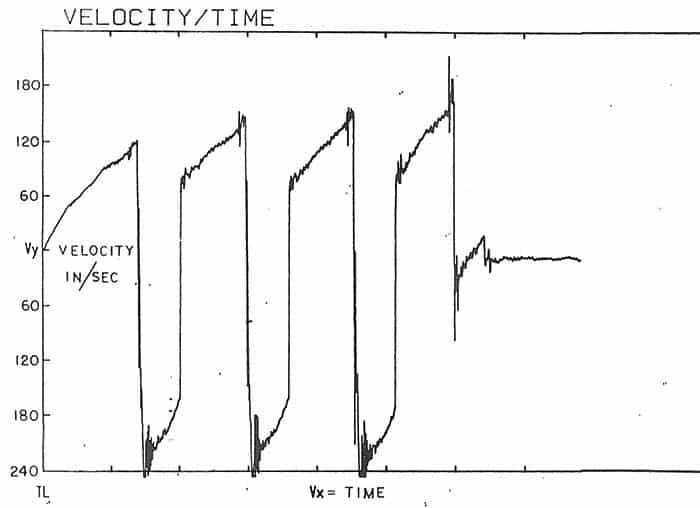

Bill, Larry, and I had a lot of fun with the new instrumentation. It was great to have the data presented immediately following the firing, so the effects of changes could be seen right away. The only drawback was the time it took us to figure out the velocity of the bolt at any given point in the cycle. This required determining at what time the event occurred using the time-displacement plot and then finding the bolt velocity at that same point in time using the time-velocity plot. There had to be a better way.

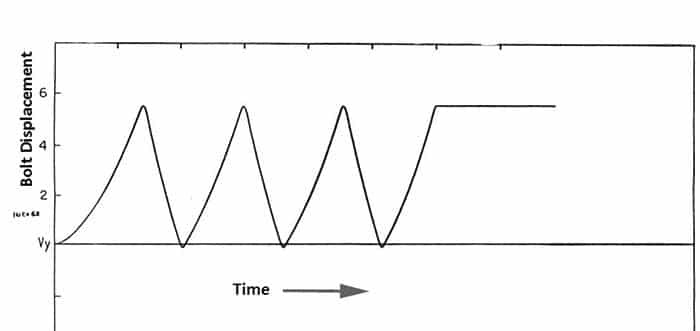

The three of us put our heads together and came up with a new approach. Since we had all the velocity and displacement data recorded, could we plot out the velocity with displacement and eliminate time altogether? We tried it and it worked! With Bill’s table of events in the gun cycle, we could tell exactly how fast the bolt was moving at every point in the cycle. The first time we saw it we were excited, but was this method really giving us accurate information? We noticed a curious dip in bolt velocity that occurred at the same point on every plot as the bolt was going forward. What was that? A quick look at Bill’s table of events chart and we knew the answer. The velocity dip corresponded exactly with the point where the bolt picked up a new round from the feed tray. At this point, a tab on the link firmly engaged the extractor groove on every round. In order to feed the round, the bolt had to overcome the grip of the tab on the extractor groove—hence the drop in velocity. During automatic fire we could watch the plotter pen go through the cycles and could see how consistent the velocity remained throughout the burst. Plotted data indicated we had an excessive amount of bolt bounce which would have to be addressed before we went into production. We ended up using these plots of velocity and displacement (we dubbed them VD curves) for every single barrel gun developed at GE thereafter.

I’ve worked with a lot of engineering technicians through the years. Most were very good, some were excellent, a few were Beeners and Chumwells, but in all of my years, there has only been one Bill Frigon.

| This article first appeared in Small Arms Review V20N1 (January 2016) |