By Tracie L. Hill

Auto-Ordnance “Bridgeport” Drums

One of the most common drum magazines encountered by Thompson collectors is what is referred to as the “Bridgeport L drum.” However, very few collectors realize that there is more than one style of these venerable drums. The following are my personal observations and is not meant to imply that one variation is rarer or more valuable than another. Rather, simply a statement of fact for collectors to start looking for the differences.

I am also not going to get into differences in markings where a comma or period is or is not visible. Collectors must remember that dies used to mark parts wear out and among the first thing that wears out are the small marks in the roll die. Manufacturers generally don’t worry about replacing a die until you cannot read all of the information. Instead, I will discuss changes of entire die sets and is what I will call a separate production run.

When Russell Maguire purchased the Auto-Ordnance Corporation on March 3, 1939, he owned a debt laden company with little assets but had some very good prospects. At the time, the Type XX Box and L Drum magazines were being produced by Mitchell Stamping Co. (M.S.CO) and probably Wooster Pressed Steel Co. respectfully. Mitchell Stamping was merged into a new company called United Specialties Company and became one of at least two different stamping divisions, with the headquarters for the new company being in Chicago.

With Maguire in control of Auto-Ordnance, the L drum production was also moved to United Specialties. The exact reason is unknown, but having one company supplying all of the magazines may have been the contributing factor. By the time that United Specialties took over the production of the L drum, the drum face plates already had the well defined drain slots and the cover markings with the “WIND TO 9 CLICKS” at the eight o’clock position on the face.

United Specialty used this design for their first L drums. The first design has the wording “WIND TO 9 CLICKS” (using .185 inch high lettering) centered on the drum face at the six o’clock position. The front face plate uses the drain slots and terminology (with slightly different alignment – i.e., a new set of dies) as the last Wooster L drum. A block outlined capital letter “U” is stamped between the front face plate rivets. The back face plate information still has the New York, NY., USA address (again with slightly different alignment than the Wooster), slightly less well defined drain slots and a block capital letter “U” (not an outlined U).

The second in the series of United Specialties L drums is the first of the “Bridgeport” address drums. This transitional drum’s front cover face plate and instructions are the same as the first United Specialties drum. However, the back face plate now has the Auto-Ordnance address as “Bridgeport, Connecticut”. There is also the “U” between the face plate rivets. This drum was probably made about the time that Auto-Ordnance built their factory in Bridgeport, circa 1941.

The third in the series is the L drum that has the instructions “WIND TO 9 OR 11 CLICKS” (using .200 inch high letters) centered on the front face. The front face plate also has the winding instructions changed to “9 or 11 clicks” and no information on the Model of 1921. Actually, the instruction to wind to 11 clicks is for the Model of 1921. The “U” is marked between the rivets on the front. The back face plate information stayed the same.

The fourth version is the first design to have the Auto-Ordnance “Thompson Bullet Logo” located centered at the 6 o’clock position above the “WIND TO 9 OR 11 CLICKS”. The “WIND TO 9 OR 11 CLICKS” (using .180 inch high letters) is a different font style than the third series as another set of dies were made. All other information on the face plates stayed the same.

The fifth and final version is very similar to the fourth and is the hardest version to visually pick up the differences on. This drum has the “Thompson bullet logo” and “WIND TO 9 OR 11 CLICKS” in what appears to be a bolder type font, using .220 inch high lettering. The front and back face plate instructions are the same though the “U” on the back face plate is now an outlined “U”.

Other World War II L Drum Production

The Crosby Co. (183 Pratt St., Buffalo, NY) – Crosby was contracted to produce the L drum by the British government in 1940. Crosby was paid $25,000 for tooling and $420,000 for the production of drums under a Defense Aid contract (DAW 740-ORD-2). By the end of the war, Crosby had produced about 243,000 L drums.

Crosby drums are considered by most collectors to be low in quality, yet if properly maintained they will function as well as any Thompson drum ever produced. It is just that they were never finished as nicely as other maker’s drums. The metal surfaces were never grit blasted and were either Black Oxide coated or painted black.

The Seymour Products Co. – These drums were originally shipped with a silver sticker label with the company name typed on and applied over the stamped markings on the front face. However, these labels were normally removed by the first users. The body is blued with no grit blasted finish applied. Seymour produced about 190,000 L drums during WWII under Lend Lease contracts. The company was awarded the Army- Navy E Award of excellence for its Thompson submachine gun magazine production on 21 August, 1943.

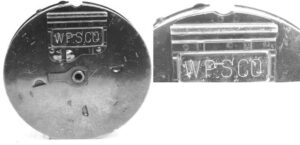

Wooster Pressed Steel Co., Wooster, Mass. – The company began production of L drums during WWII under a British contract in 1940. Prior to this, Wooster had produced L drums directly for Auto-Ordnance in the 1930’s. The British drums were produced under contract DA-W-241-ORD-726, for a total of 50,000 drums. The WPSCO drums are blued or diluted with no grit blast finish.

Charles Fischer Spring Co. – These drums were produced during WWII. However, all were rejected and ordered to be scrapped. Nevertheless, a few examples still exist today.

Robbins .22 Caliber Drum Magazine – One of the rarest of the WWII drum magazines is the drum for the Robbins .22 caliber conversion unit. Designed and built by Charles Robbins of Cincinnati, Ohio prior to the US entering World War II, it was the first successful .22 caliber conversion unit for the Thompson submachine gun. The units were all hand fabricated and sold to police and military. One sale of these units required Mr. Robbins to be recalled from the Philippines, after “MacArther’s return,” to produce the units for the US Secret Service. After the order was complete he was returned to combat.

Prophylactic Brush Co. – The Prophylactic Brush Co. was contracted by the US Army Ordnance Dept. to produce phenolic Bakelite “plastic” reinforced with hemp rope L drums in 1940. The idea was to reduce the need for steel in the production of magazines. However, the drums were a failure as the plastic drums weighed more and were even more fragile than the steel drums.

| This article first appeared in Small Arms Review V9N4 (January 2006) |