By David Lake

Polymers and Composites

Drastic changes to tradition can be a hard sell- especially when that tradition finds deep roots in history and culture. If you’re reading this, then you are part of a very special culture- you’re a “gun guy”. And if you’re over 40, then you’ll recall the arrival of plastic pistols. You’ll recall the myths purveyed by the media and the doctrinal arguments hosted by the experts who either celebrate or condemn the idea of using plastic in the construction of a firearm. Despite early skepticism and trepidation, the merit of the concept has been well demonstrated, as now almost every small arms manufacturer offers a plastic gun. Hold-outs and traditionalists are hard-pressed to disprove the advantages in cost, weight, and resilience afforded by plastic.

Accurate terminology is important to this subject. When speaking of steel or aluminum, the generic names can be acceptably applied. Steel… is as strong as steel. And that’s enough. Or close enough as it makes little difference in idle conversation. Aluminum is understood to be very respectable stuff. Structures made of aluminum spend a lot of time performing extreme duties in exotic environments. However, when speaking of plastics and polymers and composites, one must use more specific designations, as all plastics are not created equal. In fact, the word “plastic” should be avoided, as it is not a correct descriptor designation of a type of material; it only refers to a distinct property of material. “Plastic” is not an adequate label for the superlative high-tech engineered materials used to replace steel and aluminum componentry in the firearms of today.

We should at least become familiar with the nature of a polymer. Poly means many; thereby a polymer is a compound built from many other compounds. Specifically, those compounds are called monomers and as it applies to this discussion, these monomers are formed from common hydrocarbons. Yes indeed, that means volatile gasses and liquids. As an example the basic hydrocarbon ethane can be made to repeat its base molecular structure- many thousands of times to form an enormous chain (speaking to the relative scale) that effectively entangles with neighboring molecules until the new material becomes a very strong solid. The common polymers are composed of very few elements; predominately carbon and hydrogen. We also find oxygen, chlorine, and nitrogen as small constituent parts of these compounds. There is a growing branch of material science that deals with something called a fluorocarbon. Fluorocarbons are manipulated to build fluoropolymers. These relatively new materials are still being discovered and explored. They promise strength and resistance that far exceed our current and common hydrocarbon polymers. These high-performance materials are the real future of polymer science. We should expect to see this stuff employed more and more in the near future. Hold your breath for the fluoropolymer pistol.

Material scientists can tailor a polymer’s properties to fill an exact requirement. If the material needs heat resistance, there’s a monomer structure for that. If a material needs increased elasticity, there’s a monomer for that. If a material needs resistance to stress fracture, there’s a monomer suited to impart that quality. The custom tailoring is performed by carefully manipulating of the way these elements combine. The subject may seem to be high science, and indeed it is, but the basic process can be well understood with the application of some Google. It’s an interesting field and its worth some study and familiarization.

Those gun companies that have ventured into non-metal construction have implemented technology beyond the basic polymer. These materials have been combined with small fibers or particulate of glass, carbon, or even certain minerals. Short fibers or particulate elements are evenly dispersed into a polymer to form a homogenous solid. This is known as “filled” polymer. This type of material generally does not give up any of the strengths and properties of the polymer to make room for the filler. The filler may be included to mitigate some inherent weakness or deficiency of the polymer. The filler may be used only to make the structure less dense, and thus, lighter. Most often, filling a polymer with an additive is done as a means to increase strength, hardness, or resilience. Sometimes polymers are filled with materials that have lubricating qualities to reduce operating friction on wear surfaces. Some polymer structures have even been infused with evenly distributed air bubbles to create structured rigid polymer foam. Though, not a filled polymer, the integration of air bubbles demonstrates how specifically these materials can be manipulated and improved. Filled polymers are cheaper to produce than machined metal, and are adequate for low to moderate load and wear surfaces. Polymer pistol frames are cast or molded into their final detailed form in a single step- a step that only takes a few seconds. This is the process used to create the frames of the HK, FN, Glock, XD and M&P pistols.

Though it was the first to claim broad commercial success, and still remains the front runner in the market, the Glock was not the first polymer framed pistol. Heckler and Koch released a polymer pistol almost 13 years before we ever heard of Glock. Almost 57 years ago, we saw the first rifle built on a polymer receiver- a .22 rifle from Remington. The proliferation of polymer framed firearms is proof that this technology is a good thing. The exact polymer recipes used by manufactures are tightly guarded industry secrets. Though, some authoritative independent research has been conducted to uncover the mystery of the exact composition of at least one of these guns. The Glock pistol frame is made of a type of nylon- that is easy to demonstrate. But even with the required lab equipment and some understanding of spectroscopy, we can only approximate the actual formula. Whatever be the details, we know that the Glock is a close cousin of stain-resistant carpet. The commercially present polymer that shares much with Glock DNA is called Nylon 6,6. We know that Glock has further manipulated the formula of Nylon 6,6 to increase its strength and hardness. Unique to Glock’s formula is an integrated fibrous, crystalline texture throughout the frame casting- though the Glock frame is not actually a “filled” polymer. The apparent fibrous structure is engineered into the polymer itself. Glock’s frame material makes a proud demonstration of our grasp and abilities in material sciences and engineering.

Given the similar requirements of all polymer pistol frames, we can assume that all firearm engineers have chosen similar polymer formulas. One feature common to all polymer framed pistols is the tendency of those frames to utilize an internal metal structure. Some feature a molded-in steel skeleton. Some just use removable metal structure that nests into the polymer frame. Both of these measures are affected to offer reinforcement at high-load and high wear areas. Filled polymers are found in long arms as well. Any designation of an item as “synthetic” usually refers to a rifle or shotgun stock that is made of a filled polymer. These materials are more resilient than wood- sometimes even considered indestructible. They are generally featured on entry level or “working” class rifles and shotguns. Long guns clad in polymer or synthetic furniture give up all points of luxury to remain totally utilitarian.

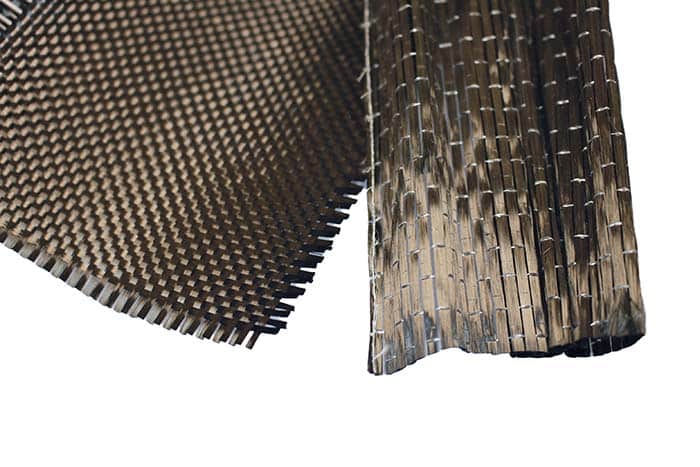

The other branch of non-metal construction involves layers of fabric woven from precisely oriented long fibers of glass, carbon, aramid, or spectra encapsulated and bonded by a polymer resin into a solid form. Aramid and spectra fiber are true polymers. Carbon fiber, though nearly 100% structured carbon atoms, begins life as a polymer film. The bonding or laminating resins used to encapsulate these fibers are also polymer, though of a special class. In theory, these thermosetting resins form one contiguous polymer molecule of the entire cured structure. The winning attribute of fiber materials like carbon and aramid is that they do not stretch- or they do, but very little. This means that a solid form made from these materials is very resistant to any change in shape. This type of structure, where linear fibers are encapsulated in a binder is known as “composite” structure. Composite manufacture boasts performance properties that far exceed the constituent parts. Though fiberglass had been popular and successfully used by gun manufacturers for many years, it has been outclassed by carbon fiber fabrication.

There are only two good reasons for carbon fiber’s popularity: it is impossibly strong and its visual appeal is timeless. As to the strength, it can bear loads and endure temperature fluctuation that could cause steel or aluminum to deform and fail. It nearly matches the strength of steel and aluminum at a fraction of the weight. This makes it good for shooter comfort. Its rigidity is far superior to that of steel and aluminum. It is less harmonic than most metals- that is, it does not propagate vibration. This is good for accuracy- as in repeatable and reliable day-to-day and shot-to-shot consistency. Composite manufacture, as it applies to gun manufacture, is usually used in high-power rifle stocks and barrels. The rifle stocks of McMillan and Manner’s are created using composite construction. The rifle barrels of Christensen Arms, Magnum and Proof Research marry carbon fiber with steel rifle barrels.

Composite construction is a very expensive and time-consuming method of construction. Complex machinery may be employed to wind fibers into a perfectly calculated pattern. Swatches of fabric are laid into a mold by hand to ensure proper alignment to achieve peak strength and beauty. Composite structures are cured for many hours under high pressure in massive ovens. Painstaking preparation, processing and finishing are required but the performance and appeal of the finished product is unmatched. The presence of bare carbon fiber garners envy at the gun range. The hypnotic weave of carbon textile or the random illusory texture of a filament wound structure adds a degree of interest and refinement to normally ordinary things. It’s inspiring and pride-inducing.

Healthy capitalism demands that all things meant to be sold should be accompanied by a fair supply of hype. The gun market is not immune to this tendency to exaggerate. Some manufacturers have labeled their filled polymer receivers “carbon fiber” and some even call simple plastics “high tech polymer.” All polymers are, generically speaking, forms of plastic, but all plastics are not polymers, and all polymers should not be considered high performance. A milk jug is made from polymer- with much science and study behind it. But it is neither high-tech nor high-performance by all standards. And when a manufacturer calls their product “carbon fiber”, it had better be made of laminated woven textile or filament wound. Both of these are easily identifiable by their unique appearance. A receiver made of an homogenous gray plastic is not carbon fiber- it is likely just a filled polymer. Even if carbon is used as filler, that material should not be described as carbon fiber. The consumer should be wary of fancy titles applied to the material from which a gun is made, and pay attention to the quality of what they can see and feel and know on their own. The overstatement of the facts is all too prevalent by advertisers and manufacturers. But we can also observe the modest understatement of facts as they apply to the capabilities and features of polymers. Most shooters don’t know that a Glock’s frame won’t melt until almost 500 degrees. Many shooters don’t believe that some polymer frames and stocks are totally chemical resistant- despite the existence of special cleaners made for “synthetic” firearms. Some just don’t believe the claims that the modern filament winding process used to replace some of the steel on rifle barrels, and the space-age resin used therein, can actually exceed steel’s tensile strength and heat-sinking abilities. Of course, this kind of peak performance asks that the barrel manufacturer exercise great care and attention to detail and perform exhaustive quality checks during and after manufacture. There are definite and distinct advantages to using new technologies in the gun market. Not all new trends should be immediately relegated as heresy. Excellence is possible, however not guaranteed when utilizing hi-tech materials. Be assured that there are indeed some promises and sales pitches that are simple farce.

One must not expect nor accept that a gun company can just replace some parts with carbon fiber or polymer structures thereby improving quality or performance of a gun. Any and all advantages afforded by the use of non-metals demand that the gun be re-engineered specifically to fully exploit a new material’s capabilities. Beware the polymer “version” of a pre-existing all-metal gun. One thing to be sure of, is that time will march on, and material science will open new possibilities. Guns will use metals less and less, and at the same time get stronger, lighter, and more efficient.

| This article first appeared in Small Arms Review V20N4 (May 2016) |