The author fires a pre-production gun at the Microtech range facility outside Bradford, PA. The gun is equipped with an ACOG sight.

By Chris A. Choat

In 1977, Steyr released what then looked like the most space-age firearm ever built: the Steyr AUG (Army Universal Gewehr). In Austria, this gun carried the model designation of F-88. It was a bullpup design, had built-in optics with not only a plastic stock but many internal fire control parts that were also made of plastic. Although it was very accurate and reliable, shooters tended to shy away from it mainly because of the futuristic look. Three decades later, the shooting public has embraced bullpup designs and the extensive use of high-tech plastics is no longer an issue. There are four or five bullpup designs that are now in production with several more in prototype stages.

One of the newest bullpups on the market is the new STG 556 from Microtech Small Arms Research (MSAR). This company is headed by President Tony Marfione and is a sister company of Microtech, well known for producing extremely high quality knives for a number of decades. Now with the new sister company, he is back on the firearms’ trail with his new American made STG 556 version of the Steyr AUG.

The MSAR STG 556 is much more than just a copy of the Steyr AUG. The STG 556 incorporates all of the improvements that the AUG should have had. Small Arms Review recently had a chance to spend several days at Microtech Small Arms Research in their Pennsylvania factory to see how this new gun is being built from the ground up.

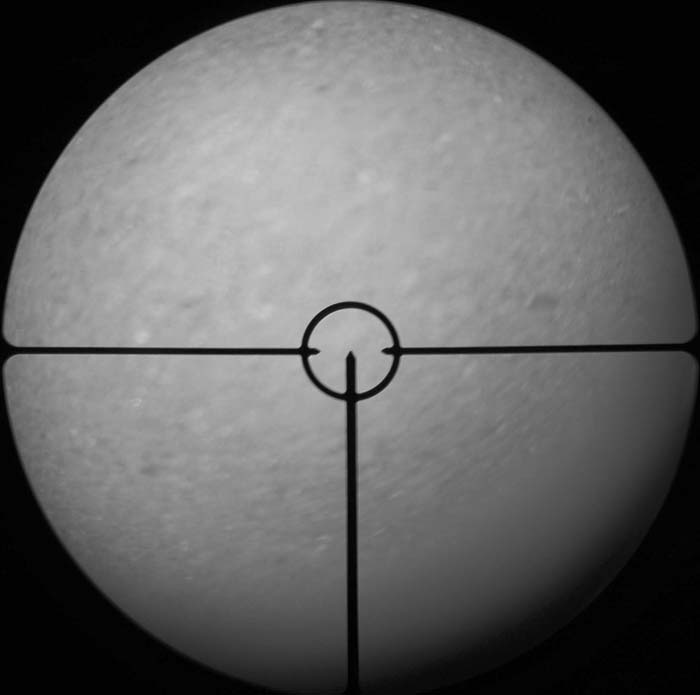

The first thing noticed when looking at the new gun are the improvements in the receiver and the rifle’s stock. The receiver is made from 7075 T6 investment cast aircraft aluminum. It is then machined on state-of-the-art CNC centers to a tolerance less than .0010 of an inch. The finish on the receiver is Mil-Spec hard coat anodizing which is then moly coated. It has hardened threaded stainless steel accessory points on both the right hand side as well as the top. These hardpoints incorporate .250×20 TPI threaded helicoils. By using helicoils instead of just threading the aluminum, a hardpoint can be replaced if someone gets wrench-happy tightening an accessory rail and strips it out. The hardpoint on the top of the receiver is probably one of the biggest improvements to the AUG style weapon. It allows different optics to be used instead of just the one that the early Steyr’s were saddled with. With the STG 556, the shooter can remove the 1.5X Steyr-type scope and replace it with the MSAR 1.5X Close Quarter Battle scope or add a flattop rail and use a crosshair target scope, red dot scope, night vision device or any combination. Any optic that can be used on flat-top receivers or rails can be used on the STG 556. STG 556s will be shipped with the standard 1.5X scope but MSAR will be offering a 3X scope with the Close Quarter Battle reticle as an option. MSAR can also renew the nitrogen in an original Steyr AUG scope as well as change the reticle to the new CQB style. A rail can also be attached to the right side of the receiver for lasers, lights etc. MSAR is offering three sizes (small, medium and large) of both top and side rails. The large top rail is just right for a combination of NV and regular optics. They will also have a lower rail that can replace the folding forward vertical grip. The rails that they offer are U.S. Mil-Spec 1913 Picatinny.

The stock of the STG 556 looks pretty much the same as a Steyr AUG from the right hand side but the left side reveals a couple of new features. The first is a forward assist button much like the one found on the AR-15/M16 rifle. With the original Steyr design you had a small button on the charging handle that had to be held in to assist the bolt closing. With the STG 556 you merely push forward on a round spring loaded button to engage the bolt and help close it. With modern firearms and better propellants, the need to “help” the bolt close because of fouling is almost non-existent but this feature makes it nice to close the bolt silently. On the right hand side of the gun, just behind the magwell, is the new last round bolt hold open release lever. The STG 556 locks open after the last shot but now instead of having to “rack” the charging handle to drop the bolt you just press on the bolt release lever and the gun goes back into battery. Several other new features are incorporated into the stock including a much better ejection port door cover. The STG 556 can be set up to fire right or left handed by changing the bolt head and switching the ejection port door cover to the opposite side. Nothing new here as the original AUG could also be converted from right hand to left hand operation. However, as owners of original Steyrs know, if you changed the port door cover on an AUG a few times, the retention piece that holds it on would give up its retaining qualities. That’s why many Steyr AUG’s that have been converted have duct tape holding on the cover. The new cover is also made from a much better polymer. The whole stock of the STG 556 is made from a very high grade polymer that is almost indestructible. The stock is injection molded in two halves and then the two pieces are vibratory welded together in house. There is virtually no seam line on the MSAR stocks as compared to the Steyr stocks that often looked as though they were glued together. The stock on the STG 556 also features drains holes so that if a gun is taken underwater, the compartments inside the stock will drain as soon as it is taken out of the water. The Steyr AUG in essence had to be disassembled and shaken repeatedly to get water out of its stock. Additionally, the new STG 556 furthermore features bolt recoil rods with drain holes in them. On AUGs, the rods could fill with water and make the gun inoperable because the water inside the rods would “hydraulic” and not allow the bolt to cycle. The buttpad on the new gun is another item that is made from a superior material called Versollan. The buttpad has a ribbed surface instead of a smooth one for better gripagainst the shooter’s shoulder.

Another new feature is the folding charging handle. While the A2 AUG did have a folding charging handle, it would sometimes lock under the front scope riser. This “event” would lock up the gun causing it to have to be disassembled to get it functioning again. The STG 556’s folding charging handle has been redesigned so that it still folds but will not jam under the riser.

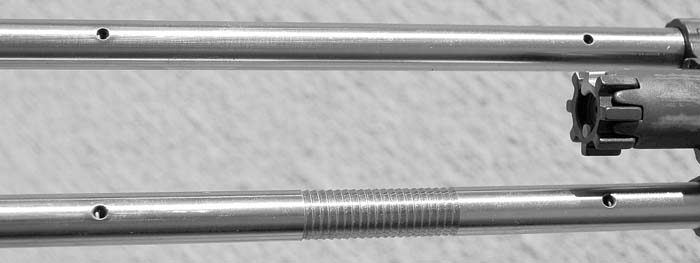

The STG 556 features the same quick detach barrel system as the AUG, but the STG barrels are fluted for lighter weight, enhanced rigidity and more surface area for faster cooling. The new barrels are made from 4150 ordnance steel, are chrome lined and are chambered in 5.56mm. All barrels are phosphated and then moly coated. They will be available in 14-inch 1 in 7 twist, 16-inch 1 in 8 twist and 20-inch 1 in 9 twist with possibly a 24-inch light machine gun style barrel to follow later. Barrels have 13×1 left hand metric threads. The new STG 556 barrels will fit the Steyr AUG rifles as well as vice versa. Even the flash hider has been redesigned. It now features a wire cutterclosed-end design as well as styling enhancements. The new flash hider will also accept the M-16 blank firing attachment.

MSAR will also offer a suppressed barrel assembly. It has long been said that an AUG could not be suppressed. This is no longer true. MSAR’s new barrel assembly will feature a non-removable suppressor that is welded together. The suppressor is made from state-of-the-art materials including Inconel and high heat stainless steel parts and features a patented sealed gas system. On the original Steyr barrels, the gas system was designed so that if a suppressor was installed, excess gases were released around the adjustable gas piston regulator and the resulting gas cloud could be seen to the side of the gun. Along with the gas cloud there was also considerable noise. With the new MSAR suppressor system, the escaping gases are captured and put back into an outer tube of the suppressor. The gases are then slowed down, cooled and vented out of small holes located around the front of the suppressor. By controlling the gases this way, there is no increase in bolt carrier velocity or cyclic rate; thereby reducing stress on both bolt and receiver. There is also very little noise. The new suppressor is reported to reduce the weapon’s report by an impressive36 decibels and virtually eliminates all muzzle flash. This new design also eliminates build-up of crud inside the suppressor.

Internally, there are also several improvements. A common problem with AUG’s that were used a lot was that the extractor pin would break, the extractor would come out of the bolt, and the gun would either lock up or would fail to extract. The STG’s extractor pin is much larger and beefier than the original AUG’s pin. The extractor is also cut slightly deeper for added grip on empty cartridge cases. Additionally, the bolt lugs are slightly beveled around the inside edge for added reliability. This allows the STG to feed virtually every kind of ammo. The ejector also has been improved. It now has two springs instead of one. Positioned one inside the other, each one is wound a different direction so that they will not “nest” and cease to function. Furthermore, all pins and springs in the new rifle are now made from stainless steel. This offers corrosion resistance as well as longer life. The bolt from the STG 556 will also interchange with the AUG.

Microtech is also making their own magazines for their new rifle. The magazines will come in 10, 20, 30 and 42-round capacities and feature innovative improvements over the Steyr design. Steyr magazines can be broken fairly easily. The new magazines from Microtech are exceptionally durable. They can be dropped, stomped on and even run over with a Humvee and they will not break. Steyr AUG magazines are sensitive to some gun cleaning chemicals that can cloud the surface or even soften the magazine body material enough that it can be scraped off with fingernail pressure. Not so with the new Microtech mags. Made from a material called Raydel 5000, not only is it chemical and impact resistant but it will also withstand temperatures to over 500 degrees. You absolutely cannot break these magazines and are so tough that they are warranted forever. The new magazines have a textured surface with cartridgecount numbers molded in. The magazine bodies are a slightly amber color instead of the green or black smoke color of the original Steyr magazines. The reason for this is that Raydel 5000 only comes in amber or black colors, so in order to have transparent magazines, amber must be used. The follower, base plate and base locking piece is made from a material called RTP, which is a fiber reinforced polymer. This material is also chemical, impact and heat resistant. MSAR’s new magazines will fit Steyr AUG’s but AUG magazines will not readily fit the STG 556.

The gun received for testing was equipped with a 16-inch barrel and the standard 1.5 power sight with CQB reticle. Initial testing was done from a bench rest at 100 yards on a perfectly still day. A variety of ammunition was used to get a feel for which type and bullet weight the gun liked. It included several Black Hills varieties, Remington 50-grain Hollow Point, Wolf Gold 75-grain BTHP, XM855 green tip and some UltraMax 55-grain Soft Point. Three shooters took turns with the gun – all firing each of the different types of ammo. It should be noted that the CQB reticle is just that: a Close Quarter Battle sight. It is not designed for target shooting at 100 yards. Even so, the rifle performed very well. Five shot groups hovered around 3 inches with just about any ammunition we used, with a couple of groups measuring just under 2.25 inches. Commendable performance for a 16-inch barreled gun with that type of sight. The rifle didn’t seem to have a “favorite” type of ammunition as it shot them all very well. Bullet type or weight didn’t seem to matter much. What shot into the tightest group for one shooter might not be the best for the next shooter.

A second session of shooting was done with the factory sight removed and the flattop rail installed. On top of this was mounted a Night Force 2.5-10×24 NXS Compact Scope. This excellent optic offers unrivaled clarity along with an illuminated, variable intensity reticle. This particular scope was equipped with the FC-2 Close Range Tactical reticle. It features a dot in circle reticle much the same as the original Steyr AUG optic except that the center dot is much smaller. Even though it is called a close range scope, with it cranked up to 10-power it gives you a very precise aiming point at even at 200 yards. Shooting again at 100 yards with the Night Force scope, groups shrank to under one inch. If the shooter does his part this rifle is more than capable.

Reliability of the STG 556 was perfect. There was not one failure in well over 500 rounds of all types of ammunition. The rifle was not cleaned or lubricated during the test and the gas plug was left at the standard “S” position. The rifle also has a setting marked “H” that allows more gas pressure to be bled off to cycle the gun when it becomes fouled. There is also a grenade launching setting marked “GR”that shuts off the gas port for launching various rifle grenades.

The Microtech STG 556 is able to be ordered as a basic rifle or in a Limited Edition kit. The basic rifle is just that: the black rifle and one magazine. No options and no frills. The Limited Edition kits will feature the STG 556 in either tan, OD green or black. It will come in a color matched Pelican 1700 rifle case with wheels, one top optics rail, one side accessory rail, one of each of the four sizes of magazines and a Microtech Currahee knife with color matched handles and color matched sheath. The knife also has a serial number matched to the rifle. Last but not least, a Giles Wilderness sling with quick-detach Uncle Mikes sling swivels. These Limited Edition rifles are definitely a must have for serious collectors.

The first STG 556s will all be in .223 caliber. Other calibers are planned. By the time this article is in print, guns will also be available in 6.8 SPC. Conversion kits can be ordered for shooters that already have guns in .223. The kits will consist of a barrel, bolt and magazine. With one of these kits, owners of Steyr AUGs can also convert their guns to this hard hitting caliber. As Microtech is the manufacturer, parts will be plentiful and will be budget friendly. AUG owners will now be able to get parts for their guns as well as upgrade them to STG 556 specifications. Select fire guns will also be available as post samples to NFA dealers, law enforcement and government agencies.

The initials “STG” are an abbreviation for Sturmgewehr, or Storm Rifle, and this new rifle will definitely take the shooting public by storm. It is very accurate, totally reliable and exceptionally well built with a long list of new design features.

Sources:

Microtech Small Arms Research, Inc.

Dept: SAR

300 Chestnut Street Ext.

Bradford, PA 16701

Phone: (814) 363-9260

Fax: (814) 363-9284

Website: www.msarinc.com

LightForce USA, Inc.

Dept: SAR

NightForce Optics

1040 Hazen Lane

Orofino, ID 83544

Phone: (208) 476-9814

Fax: (208) 476-9817

Website: www.nightforcescopes.com

| This article first appeared in Small Arms Review V11N6 (March 2008) |