By Frank Iannamico

The Italian Beretta 38/42 submachine gun is probably one of the most anonymous submachine guns that was issued in World War II. The Berettas have often been transcended by the better known German MP40 machinenpistole and the U.S. Thompson submachine gun. Hollywood and television are partially responsible for the Beretta’s lack of prominence. It has probably been ignored by film makers because of its unassertive carbine like appearance.

The fact is, the Beretta subguns were arguably the best weapons of their type issued during WWII, and had a more successful post war commercial career than any other submachine gun used in the war. The WWII Beretta subguns were manufactured with slight modifications up until the 1960s. During WWII the Beretta earned respect from troops on both ends of its sights. Since Italy was an Axis power allied with the Nazis, some Beretta subguns were obtained by the German Wehrmacht. The aggressive German Army issued submachine guns to their troops in far greater numbers than the Italians.

The Moschetto Automatico Beretta 38 series of weapons were designed by Tullio Marengoni, a talented Italian designer. One of Marengoni’s earlier efforts was the Beretta Model 1918. The model 1918 was based on the Villar Perosa design. He is better known for his 38 series weapons, the first of which was the prewar 1938A model. The early 1938A Berettas rival the famous Colt produced 1921 Thompsons in quality of construction. The fine 1938A model would continue to be manufactured, in several variations, until 1950.

As World War II continued, the Beretta 1938A was redesigned by Marengoni to be produced faster and cheaper, to keep up with the increasing demand for weapons. This trend to expedite war time production was being practiced by every country in the war that was producing weapons. The result of his efforts was the Moschetto Automatico Beretta 38/42 submachine gun, or the MAB 38/42.

Although the Beretta 38/42 design lacked the refinements of the previous 1938A model, it was actually handier and faster on target than the larger, heavier 38A. Gone were all the milled steel machined parts, replaced by sheet metal stampings. The polished blue finish of the 38A was also deemed unnecessary and the 38/42 models were finished in a dull blue/black. Most of the functionally important attributes of the 38A were retained. All Beretta subguns used the common open bolt/ blow back design. Beretta manufactured subguns also feature a non-reciprocating cocking knob/dust cover. While the gun is firing, the cocking handle remains stationary and the dust cover encloses the actuator slot to keep out debris that might lead to untimely stoppages.

The 38/42 features a simple folding leaf sight, calibrated for 100 and 200 meters. The front sight is an unprotected blade type. Early models had a fluted barrel to aid in heat dissipation from extended firing. An easier to manufacture smooth barrel was fitted to later production guns. Beretta barrels were made from nickel steel and rifled on a broaching machine. Both style barrels had two compensator slots cut into the top at the muzzle.

The 38A dual trigger configuration was retained in the 38/42 and subsequent models. This feature would become a trade mark of Beretta submachine guns. The front trigger controlled semi-automatic fire, while the rearmost trigger was for the full auto function. The rear full auto trigger is serrated to aid the operator in knowing what trigger his finger was on in low visibility situations. The bolt is machined from nickel steel. The sear is made from heat treated steel, as are the trigger group components.

The Beretta wooden stocks are made from dried beech. The 38/49 and later models could be ordered with a walnut stock. There were a few prototype 38/42 models with a folding stock similar to the German MP40. This was called the Model 1. A similar folding stock gun was patterned after the 38/44, it was the Model 2. Neither gun was mass produced.

After the Italian Army finally capitulated in September 1943, the Germans continued to occupy Northern Italy where the Beretta plant was located. Manufacture of the Beretta 38/42 continued under German supervision. 38/42s produced under German occupation of the factory are often marked with Nazi Waffenamts. The stocks on these Berettas are stamped VT inside a circle. The Nazi designated the 38/42 subguns as the MP740(i). The Nazi troops highly regarded the Beretta, mainly for the accuracy in both full auto and semiauto modes. The Berettas saw much action in the Italian and North African desert campaigns. The Berettas were also utilized by the Italian partisans that caused a lot of grief for the Germans troops occupying their country. Romania also purchased 38/42s during the war.

The Beretta factory produced weapons throughout the course of the war, and continued to manufacture weapons even after the war ended. The 38/42 design was simplified by designers near the war’s end. This was done with an eye towards post war export sales. The new model was designated as the 38/44, introduced in 1945.

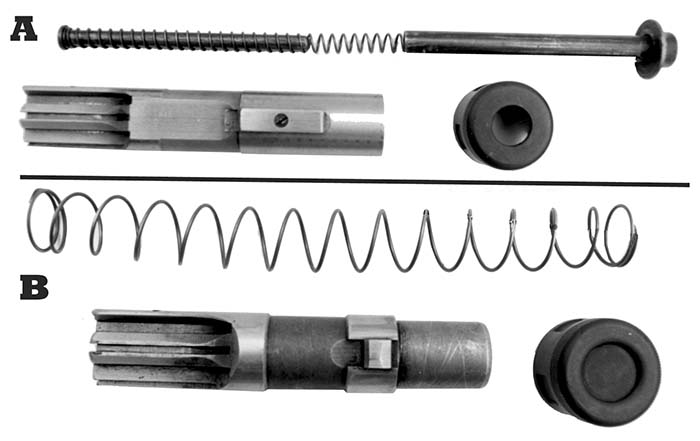

The modifications this time were very minor and consisted of a change to the bolt and recoil spring design. Instead of using the smaller spring and guide rod configuration of the 38A and 38/42, the 38/44 used a shorter, lighter bolt and a large recoil spring that slid over the rear of the bolt. The bolt in the 38/42 is 9.1” long, while the 38/44 bolt measures 5.9”. Both bolts have a fixed, integral firing pin protrusion. A new receiver end cap was fitted, without the hole that the previous models had for the recoil spring guide rod to protrude through. Despite the lighter bolt the cyclic rate remained the same, due to the heavier recoil spring. All 38/44 models had the same smooth barrel of the late production 38/42 model.

The parts between the 38/42 and the 38/44 are totally interchangeable. Simply by switching the bolt and recoil spring, a 38/42 can be changed to the simpler 38/44 configuration and vice versa. Other parts, stock, barrel and trigger group are also the same. Many references state that the two piece recoil spring guide assembly of the 38A and 38/42 models made the guns operate smoother. Although this may or may not be true, I found no evidence of such. To me both guns seem to shoot identically. 38/44s and later models were sold to Syria, Pakistan, Iran and Costa Rica.

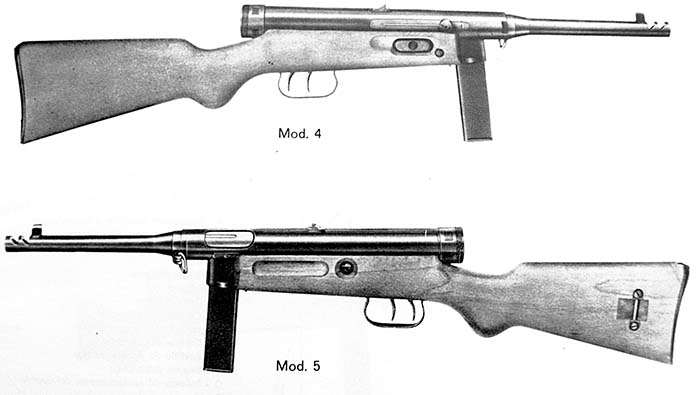

Soon the Beretta 38/44 submachine gun evolved into yet another model, the 38/49. Again the changes were minimal, and consisted mainly of a new cross bolt safety. The 38/49 was aimed towards commercial sales, and many were sold to post war Germany, mainly for police use. The Germans designated their Beretta 38/49s the German MP1 model.

Beretta eventually stopped using year designations in their model numbers. The factory management felt that by designating models by the year they were designed, it gave potential customers a perception that the guns they were buying were of an old design (in fact they were). The 38/49 designation was changed to the Model 4.

B: Bolt, recoil spring, and end cap of 38/44, 38/49, model 4 and model 5.

In 1957 another variation was introduced, the Model 5. The Model 5 remained virtually the same as the previous model except for a grip safety feature. The odd grip safety is located in the finger groove of the stock, just behind the magazine well. The grip safety is designed to be activated with the shooter’s weak hand. The bolt cannot be retracted unless the grip safety is depressed. It will also lock the bolt in the open position if not depressed. The Model 5 was produced until 1959. Some of Beretta’s customers, most notably the German police, preferred the Model 4 without the grip safety feature.

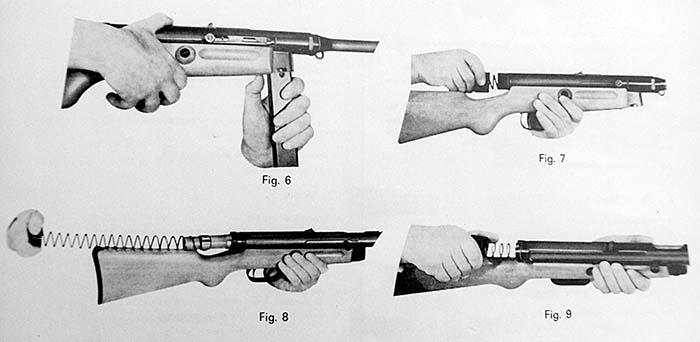

A. Clear weapon, remove magazine. B. Twist receiver end cap, remove slowly. C. Remove recoil spring and bolt assembly. D. Reinstall bolt, spring, and cap.

One of the components that helped make the Beretta submachine guns such a success was its excellent double feed magazine. The double feed design was much less prone to jamming, required less spring pressure to operate, and was easy to load. The Beretta box type magazines were made in 20, 30 and 40 round models. Even though the double feed magazine design was the most reliable, the single feed, double stack magazine was the most common design used on most WWII submachine guns. The German MP40, U.S. M3, and the Russian PPSh41 all used the double stack, single feed design.

The UZI magazine is a direct copy of the successful Beretta design. The U.S. Thompson submachine guns also used a double feed magazine during WWII, but it wasn’t as durable as the Beretta magazine that was made of heavier gauge metal. Another positive feature of the Beretta magazine is that they will interchange and function in virtually all the Italian subguns produced! Of interest to today’s shooters, the aftermarket Uniclip reloading system made for fast loading of the UZI magazines works perfectly on the Beretta magazines.

The Beretta subguns today are occasionally offered by dealers or individuals. The highly desirable 38A models are usually the most difficult to locate. Both the 38A and 38/42 Berettas are listed on the BATF’s Curio and Relics list. The 38/44 and later models surprisingly are not listed, although some may be transferable as C&R guns.

A few years ago the somewhat obscure Beretta subguns were real sleepers, and could be purchased at very reasonable prices. Those days unfortunately have long since passed.

If you ever have the chance to own or fire any of the Beretta subguns, you will discover what the TV and movie producers obviously didn’t… what a fine accurate weapon the Berettas really is, despite its docile looks.

| This article first appeared in Small Arms Review V1N9 (June 1998) |