By Mark White

As a battle rifle the M16 is an excellent weapon with one major flaw. Its gas system dumps burned powder residue directly into the action – hence it must be kept fairly clean in order to function reliably. It was said that Stoner considered an operating rod system, but rejected it because he felt that it would be detrimental to accuracy. While the Russian AK 47 may not be as inherently accurate as the M16, it is definitely a more reliable design. Filled with sand, lying in mud, allowed to get rusty, the AK 47 will still fire when called upon. A bit of sand, a primer, or a small pebble in the M16’s action will tie it up. THE M16 MUST BE KEPT VERY CLEAN IN ORDER TO BE RELIABLE. M16s & AR15s come with a number of different barrel lengths – 6”, 10.5”, 11.5”, 13.5”, 14.5”, 16”, 20”, 24” & 26”. As usual, the shortest and longest are of limited value. Initially developed for varmints in the United States, the .223 cartridge was carefully redesigned to be a very efficient, high-pressure military round. I personally feel that the military developers should have gone to a slightly larger diameter bore (like 6mm) in order to provide greater volume and mass for the projectile, however no one bothered to ask my opinion at the time.

The report from an M16 with a short 6” barrel releases a blast that is absolutely devastating. The shooter feels the impact deep in his chest and forehead, even with very good ear protection. Weapons with 6” barrels are prone to burning holes in their gas tubes. The longest 24”& 26” M16 barrels are also freaks. They deliver fractionally better energy than barrels of medium length, but not nearly enough to justify the added length and bulk. The U.S. military conducted quite a bit of testing with different barrel lengths – finally settling on an 11.5” barrel in combination with a slightly collapsible buttstock for light duty and close combat, a heavier 14.5” barrel for intermediate range and general issue, and a 20” barrel for longer range. Other lengths are available in the civilian market. In use, the 11.5” barrel doesn’t provide a long enough push through the gas tube for proper cycling – hence the chamber is purposely made sloppy, the gas port in the barrel is enlarged, and additional areas are tweaked to aid functioning. Dr. Martin Fackler, a highly respected military wound ballistician, feels that the 11.5” barrel robs the bullet of too much energy, and has serious concerns about its effectiveness in combat. Some M16s with 11.5” barrels are very reliable, but many more are prone to malfunction. A few manufacturers are making M16s with adjustable gas ports, and these are more likely to cycle with subsonic ammunition when adjusted for maximum gas flow. The adjustable gas port is a good idea for a number of reasons. It can be turned to minimum input for hot ammo, or turned to maximum in situations of extreme cold, or when the weapon is exceptionally dirty. The downside of the adjustment is that one must be careful and sophisticated in its use, as too much pressure could eventually damage the action or receiver.

We talked with a number of different firearm experts, and all agreed that weapons with barrels longer than 14” are more reliable than weapons with very short barrels. However, if a weapon with a short 11.5” barrel has cycling problems, those problems will usually go away when a suppressor is attached, as a can holds the pressure in the barrel and gas tube for a much longer period of time. Those in enforcement absolutely must have reliable weapons. With a 55-grain military round, expect about 2,780 fps out of an 11.5” barrel, 3,050 fps from a 14.5” barrel, 3,120 fps from a 16” barrel, and 3,280 fps from a 20” barrel. Muzzle energy is found by squaring velocity in fps, multiplying that by the weight in grains, and dividing that figure by a factor of 450,400. Respectively, the 11.5” barrel will deliver 944 ft. pounds of energy at the muzzle with a 55-grain bullet. The 14.5” barrel will deliver 1,136-ft lbs., the 16” barrel — 1,200-ft lbs., and the 20” barrel — 1,314-ft lbs. The 11.5” barrel thus delivers 80% of what the 16” barrel would, and 72% of what could be expected out of a 20” barrel. Remember that a tiny round that enters a vital area with a velocity substantially below 2,200 fps will not deliver a high level of stopping performance. Relatively heavy rounds tend to get more energy out of a short barrel than light rounds, but they will also penetrate walls beyond the primary target more heavily.

Several we talked to really like the M16 with the 11.5” barrel for its maneuverability. Most like the M16 with a 14.5” or 16” barrel. The 14.5” and 16” barrels deliver the most energy and accuracy for their weight and bulk. Few accomplished marksmen would hesitate to take a 200 yard shot with one, and we have found the three short barrels just mentioned usually more accurate than a 26” barrel. This is because barrel harmonics are lower and more stable in a short barrel. When a bullet spends less time in the tube it is more likely to be delivered in an accurate and consistent manner. We will talk about this in depth later, but a thicker muzzle is usually more accurate than a thin muzzle.

The light .223 bullet needs substantial velocity in order to work effectively. Initially the boat-tail round was designed to be marginally unstable, spun with a slow 1 turn in 14” twist. It tumbled on contact, breaking in half at the cannelure and causing two jagged wounds in one. Unfortunately the slow barrel twist caused problems in cold temperatures. Under Arctic conditions the weapon wouldn’t stay on a dinner plate at 25 yards. Eventually a faster twist was adopted. NATO trials were held in Europe, where it became apparent that a more streamlined, heavier bullet would be more accurate and more effective at longer range. The standard round was lengthened and streamlined, resulting in the 62-grain bullet we have today. The 62-grain bullet needs at least a 1 in 9” twist. The long-range 70, 75 & 80-grain bullets need a 1 in 7” twist in order to work effectively at all temperatures. LE personnel and civilians are not bound by the Geneva Accord, hence may use any bullet that will do the job (within their own legal limits, of course). Loaded ammunition is currently available in weights ranging from 40 to 150 grains, with 80 grains being the upper limit for lead-cored supersonic projectiles.

Heavier .223 bullets are more strongly constructed, and will penetrate fairly well. Lead melts at 700 degrees F. On a warm day a lead-cored bullet will easily reach these temperatures from the combined influence of bore pressure, bore friction and air friction. Lightly constructed varmint bullets often blow up on the way to the target, as they were never intended to spin as fast as 337,000 RPM (in a 7” twist barrel), and should not be used. A number of police departments have adopted the 40-grain bullet for use in entering trailers and apartments, as this light bullet typically dumps its energy quickly, and tends not to penetrate as many walls beyond the primary target. A light .223 round is preferred over a 9mm or .40 S&W round, as it will not penetrate walls as easily. Its effect during a headshot is devastating and instantaneous. Hornady builds TAP (tactical application, police) .223 (and .308) rounds in assorted weights that are designed to function in enforcement applications. We have not tested these extensively, but plan to in the near future. Jeff Hoffman of Black Hills Ammunition Co. favors their 60-grain softpoint bullet as an all-around, .223 enforcement and hunting projectile. It is a tough bullet that opens well into a classic mushroom, and tends to stay within the primary target. It is very accurate and very versatile. Ammunition manufacturers are very responsive of late, and are struggling to give the industry anything it will perceive as better. Other rounds that come highly recommended are Federal and Winchester’s 69 grain JHP, and Black Hill’s 68 and 75 grain JHP. If you have a Vietnam-era M16 with an older barrel with a 14” twist these longer bullets will not stabilize. They will tumble end-over-end as soon as they get out of the muzzle. One must have a barrel with a 9” to 7” twist for the heavier bullets.

For a JACKETED, SUBSONIC ROUND in suppressed weapons we like Speer’s 70-grain semi-spitzer, soft point, as it comes closest to a round-nose, flat-base bullet. These are not yet available as loaded rounds. Loaded subsonic .223 ammunition is currently available from E B R at 512-360-5327, and H J B R at 256 447 1987. It will eventually be available from Black Hills as well. The point of impact (POI) of subsonic rounds will be different from supersonic rounds (usually much lower and a bit left) because of different recoil characteristics. Some who use both rounds in the same weapon use an optical sight for high-powered ammunition, while the weapon’s iron sights are adjusted just for subsonic rounds. While expanding the versatility of the weapon, subsonic bullets out of a suppressed weapon typically do not have the energy to do much upon hitting a target. Another sighting technique is to use the lower part of the vertical part of a duplex crosshair as the aiming point for subsonic ammunition. Extensive practice is recommended to achieve familiarity with both types of ammunition. Again, don’t expect very much performance out of subsonic .223 ammunition, as there isn’t much energy involved.

Aguila currently distributes a .22 LR round that weighs 60-grains. These do not work very well in M16s that have been temporarily modified with a Ceiner conversion kit. They jam, and a single round loudly dumps its gas out the breech because the shell is very short. Subsonic 40-grain ammunition works in the conversion kit, but the kits have to be polished and reworked in most cases. They must be kept clean and well oiled for any sort of reliability. Subsonic ammunition delivers a small fraction of the energy to the target, but the sound level from a suppressed weapon is virtually undetectable. Supersonic ammunition is more fun, and unlike subsonic, will cycle the M16’s action reliably. Coconuts, tomatoes, cabbages and water-filled jugs make interesting targets, especially with some of the hyper-velocity varmint rounds.

Remember that hot weather will increase pressures and velocities, sometimes to the point where non-crimped primers fall out of fired, commercially loaded cases, tying up the action. We wouldn’t be mentioning this if it weren’t a problem, especially in those AR15s that have been “protected” with a steel anti-auto block in the receiver. It is during hot weather (or in a very hot barrel) that chances are greatest that the lightest weight, hyper-velocity ammunition will come apart in the faster 7” twist barrels. When this happens, the rounds will turn to copper foil and droplets of molten lead in the air. They will not retain their integrity, and will not strike a target.

For law enforcement use the M16 with a 14.5”, heavy barrel (H-BAR) represents the best compromise. There is enough length for reliable functioning and adequate ballistic performance, yet the weapon is still short enough to be handy. Some in LE are uncomfortable about the fact that either a short 14.5” barrel or the full-auto M16 constitute restricted, NFA weapons. There is some merit in the fact that, if a police duty weapon is used in a raid, and if it is a machine gun or NFA weapon, some bad press or legal problems could possibly ensue. The AR15 with a 16” barrel will neatly sidestep this issue. Both the 14.5” and the 16” barrels are short enough to be handy. The general public has seen the M16 for over 35 years. They are thus conditioned to its presence and view it as an “old” rifle, which is a positive public relations feature. Weapons that are smaller in stature are perceived as less dangerous than physically larger weapons. If the M16 is hanging by its sling against the side of an officer’s body in a muzzle-down position it will be perceived as less threatening (by the general public and press) than if it is brandished or carried in the ready position on the way to deployment. Loudness of the .223’s intense report is also an important public relations concern, and less noise is always better than more noise. A small silencer is a useful accessory, as is a flat-topped, receiver with a rail. If a scope is used the flat-topped upper and a gas block without a front sight tower are both quite useful. A scope mount that attaches to a carrying handle offers versatility, but puts the sight radius so high above the stock that it is awkward and uncomfortable to use. A flip-up rear sight is a handy backup for an ACOG sight, and both can be used together at the same time. SIGHTS THAT REQUIRE BATTERIES WILL OFTEN NOT WORK WHEN THEY ARE NEEDED, AND SHOULD NOT BE CARRIED UNLESS CHECKED CONSTANTLY. Don’t be lured by the apparent ease of use of these sights. All one has to do is forget to turn one off, and it will be absolutely useless a week later.

Curiously, flash hiders are perceived as silencers by the uneducated general public, as are tactical lights that look like they would work as silencers, even though they are not attached to the end of a barrel. Both the 14.5” and the 16” barrels cycle an action reliably. Both barrels will deliver powerful and accurate fire up to about 300 yards. These two barrel lengths make the M16 or AR15 very useful entry guns for raids and hostage rescue. The only barrels we endorse are 14.5” and 16” H-BARs, although we know that many have had very positive experiences with the short 11.5” barrels.

The military designates the weapon with its flawed 14.5” barrel the M4-A1. Curiously (and unfortunately) the rear portion of the standard M4 barrel is turned quite thin, at a touch over 5/8”. WE VIEW THIS REDUCTION IN DIAMETER AS A REAL MISTAKE, AS THE THINNER BARREL LACKS THE ABILITY TO REMAIN RIGID AND ABSORB HEAT LIKE THE H-BAR. The M4-A1 barrel was designed for a grenade launching attachment, and for this process a deep groove was cut forward of the front sight We feel that the reductions in barrel diameter seriously degrade the weapon’s accuracy potential. Dr. Philip Dater at Gemtech used such a barrel in the testing of his cans, and had his barrel bulge at the groove in front of the sight tower. Heat was probably a factor, combined with pressure. The bulge did not diminish the accuracy potential of the weapon. We are told that Colt delivers only this barrel with their version of the M4-A1. One can buy M16s and AR15s from Bushmaster or other manufacturers. Upon request they will provide them in the short H-BAR configuration without the offending rear reduction and groove in the barrels. Buy the weapon in the configuration you desire. An LE agency should not significantly alter weapons after they are purchased, as that may turn into a point of contention in court after a shooting. CYA.

It is said that Bushmaster makes the best weapons in the business today, although Colt has the reputation, having been in the business for over 160 years. The Commando-style, sliding buttstock is flimsy, but does offer a temporary 4” reduction in overall length. It is painful for anyone with a beard to use. We recommend the solid, plastic buttstock with a rubber buttplate instead, in the shortest version possible, and without a butt trap. This stock is steadier and more workable, yet still provides enough shoulder room for web gear and body armor. If you already have an M4-A1 with the defiled barrel, Bushmaster and other manufacturers will sell you a drop-in, match quality, post-ban (unthreaded) replacement barrel with all the hardware (barrel nut, gas tube, forearm and front sight group) for roughly $200. An LE agency should send the entire weapon in for modification and replacement of critical parts. Test the weapon extensively upon its return. CYA. A 7” twist is preferred only for long distance shooting with very heavy 70 & 80-grain bullets. The 9” twist is more desirable, as it is considered to be more versatile. Cartridges containing sharply pointed 70 and 80-grain bullets will not fit in standard magazines, and must be loaded into an M16’s port individually, by hand. This of course reduces a machinegun to a single shot, hand loaded rifle. Most Colt and Bushmaster barrels have chrome-lined bores. While not normally quite as accurate, chrome-lined bores are less susceptible to corrosion and wear, a consideration for a weapon that may only be cleaned infrequently.

When a law enforcement entry team is inside a building the members usually have one or both ears unprotected in order to hear the movement of suspects. Firing an unsuppressed M16 in a confined area is not only extremely painful and damaging to unprotected ears, it also destroys an officer’s ability to hear the continued movement of suspects. The report is so severe that perpetrators and officers have been found to be bleeding from the nose and ears if a .223 round was fired inside a room that they occupied. The flash from an unsuppressed weapon can also blind a shooter temporarily in a darkened environment. We strongly recommend that the AR15 or M16 be equipped with a small, compact sound suppressor to take the edge off the severe blast, and the sometimes substantial flash. A good flash hider of the vortex type will remove muzzle flash, but the felt report will be louder to the shooter’s ear. The down range report may be lessened to a substantial degree by some flash hiders and muzzle brakes. The assault rifle ban hasn’t helped us with regard to sound suppressors. It is not currently legal to mount a silencer or a flash hider on an AR15 with a post ban receiver, hence the rising value of pre ban lower AR15s. The receiver is of course the critical part, and listings of serial numbers are somewhat available to help determine which receivers are pre or post ban. BATF hasn’t made a serious effort at prosecution yet, but the day may come. The current unwritten rule of thumb is, if a prosecution will make headlines, BATF will make the effort. Again, law-abiding citizens and businesses are much easier to prosecute than criminals because they stand still and cooperate.

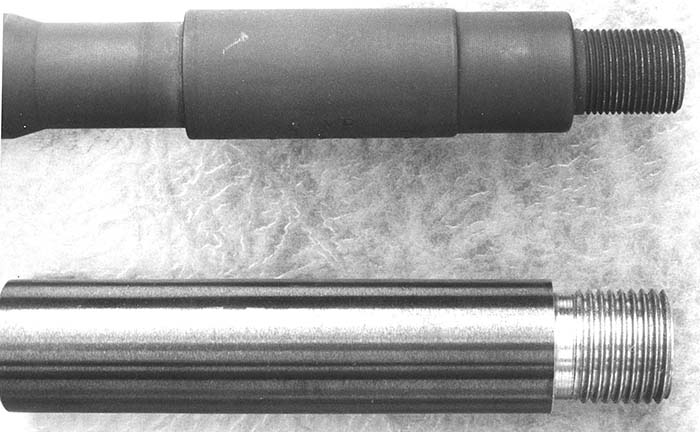

While there are a number of quick-release couplings on the market, we recommend the time-honored screw connection. Here’s why – the standard barrel threading at the muzzle is 1/2-28, which means that the very end of the barrel has been reduced to a mere 1/2” in diameter, and at the root of the threads the diameter is less than 7/16”. The grooves at the base of the threads act as stress concentrators, helping to propagate tears or cracks in the parent metal. While that threaded stub may be adequate for a flash suppressor, it is barely adequate as a base for a longer, heavier sound suppressor, which generates a considerable forward pull with each shot. The pull is very sharp and very strong, and in our view the small 1/2” thread is doomed to eventual failure if enough (2,000 to 10,000) cycles are loaded onto it. All or most quick-release couplings rely on a flash suppressor or lugs as a base for the connection. Ultimately one has everything hanging on a threaded, 1/2”-diameter stub with a .224” diameter hole in the center of it. Given the opportunity we would always opt for heavier threads. During the strain of a forced entry an officer may end up using his weapon as a punch or ram, and a heavy mount on a heavy barrel will more easily handle that strain without damage. We know you are not supposed to do that, but it happens. When one screws a can onto a heavy mount he knows it’s solid. It takes about 15 seconds to install a can on a threaded connection. Simplicity in this case is a virtue. A quick-release coupling is often weak, and sometimes not reliable. We have seen a can launch down-range more than once because the coupling either gave out, because the lugs weren’t properly seated, or because-the system loosened — allowing axial misalignment and bullet strike. The third sin of the snap-on coupling is not releasing on command. Corrosion, carbon buildup, or the failure of the spring-tensioner/piston has been known to cause the system to seize up. Accuracy problems have been traced to quick-release couplings that shot or wore loose, allowing slight baffle contact. Barrels have been bent and cans have been destroyed while trying to get frozen couplings to release. These couplings usually work fairly well when they are new and freshly greased. Shoot through one several hundred times and put it in the trunk of a cruiser, wet. Leave it there, unattended, for a few months in southern Florida. Humidity combined with heat will almost guarantee corrosion/seizure problems.

If we were given an unthreaded, heavy match barrel (H-BAR) we would probably turn and thread the muzzle at 11/16” or 3/4” NF, LH rather than 1/2-28. Indeed, if the 3/4” diameter of the hole in the front sight tower were not an issue we would machine a heavy flange near the barrel’s muzzle and install 3/4” or 13/16” – LH threads at the muzzle for a more serious attachment point. While a two-point mount may be more secure, it is more likely to seize up than a single-point mount. When a two-point mount seizes it is extremely difficult to get penetrating oil where it is needed. A large, single-point mounting system may be non-standard, but it is far stronger and more rigid in all respects. The industry trend is toward single-point mounting systems, as they tend to be inherently trouble-free if made large enough to handle the stress of firing and abuse. Left-hand threads tend to self-tighten at the muzzle, while right hand threads tend to loosen in reaction to barrel torque as each bullet is spun in a right hand direction. That doesn’t necessarily mean that LH threads will always stay tight, but they don’t tend to loosen as easily as right hand threads. A suppressor needs threads to pull on and a shoulder to rest against or it will not stay in line with the bore. The threads tend to center the can axially, while the shoulder holds and controls angular alignment (as long as the can remains tightly screwed in place). If the threads and shoulder are very close together the system is referred to as a single-point mount. If the threads and shoulder are from 2” to 10” apart the mounting system is referred to as a two-point mount, and here the threads are usually buried deep inside the center of the can. Both types of mounting systems will compensate for the considerable amount of wear that occurs as a can is screwed on and off its barrel. Wear occurs from three main sources. First, the intense forward pull following each discharge applies considerable stress to the threads. Second, ground glass particles from the priming materials are thoroughly distributed over the thread surfaces. Third, the high mechanical advantage of threads also applies a lot of force to all surfaces. This is why we prefer large diameters and a generous shoulder or flange, so that wear will not be as significant. Cross threading is occasionally a problem, and the only cure for a butchered thread is to cut the barrel off and re-thread it properly. The bottom line in all of this is that a simple, single-point, threaded mount of massive dimension will provide the best service with the least amount of trouble. If left-hand threads are used the rear of the can should be stamped LH to eliminate confusion for those who can read.

It has been mentioned that post-ban barrels are typically shooting more accurately than pre-ban barrels. This is probably due to the fact that pre-ban barrels are turned down to 1/2” diameter at the muzzle. Most barrels are button rifled, and the rifling process puts a lot of internal strain on the barrel metal. Turning the outside diameter thin reduces that strain, and has the effect of enlarging the bore at the muzzle, which is the place where the bore should be the tightest, not loosest. As far as accuracy is concerned, the best results will occur when the barrel is thickest at the muzzle. Many European target weapons are built that way, but the practice never caught on in the U.S. Putting a can on a muzzle does stabilize it to some degree, but it doesn’t usually tighten the bore at that point. Accuracy problems have been traced to asymmetrical blast baffles and to baffle apertures that were too tight to allow bullets to pass without striking. One last thought with regard to the small 1/2-28, threaded barrel stub – if a flash hider or a sound suppressor is screwed on too tightly it can have a detrimental effect on accuracy. This is of little consequence on an entry weapon, but can be a problem on a varmint rifle. The tightness of the can or flash hider will not be as much of an issue if the threaded muzzle stub is of a substantially larger diameter.

The .223 is such an intense cartridge that heat gain becomes a problem when a suppressor is attached. The more effective and the more compact a can is, the greater the heat gain. While rapidly shooting 20-rounds of military ball ammunition won’t present a problem, 50-rounds might. In combat, we feel that one should use carefully aimed shots and be conservative with ammunition.

Because water is a major byproduct in the combustion process, a good deal of it will get trapped in a suppressor. A suppressor should be removed and allowed to air dry after each firing session. The internal baffles and the threads should be lightly oiled or greased to protect them from corrosion. We use TSI 301, Corrosion-Bloc, Boeshield T-9, or RIG (rust inhibiting grease). RIG will vaporize and leave a cloud of smoke in front of the weapon, which could cause a problem in some circumstances. Left-hand threads are good here, as they don’t loosen as easily during firing. A suppressor will rust in place it the moisture aspect is not attended to. The rear part of a two-point mount acts like a seal against the slight swelling of the barrel just forward of the front sight tower. It will wear a bit with each use, and the seal will get better. The seal between the front sight tower and the gas port in the barrel is often less than perfect. High-pressure gas leaking here has been known to cause some amount of noise. A small bit of J B Weld applied before assembly will help. If you do this be sure that none gets into the barrel port or it will prevent proper cycling. Always store the weapon in a level position, or point it muzzle-down, with the action locked open. Do not store the weapon pointing up, as gravity will cause dirt and particles to fall downwards and lodge in the action. If the action is locked open, air movement will help dry accumulated moisture.

If suppressors are used, we believe that one should sight in and practice with them in place. It will not do to carry a suppressor in a pouch, to be used if one feels it might be beneficial at the time. Any weight placed on the end of a barrel will change its point of impact A can should be removed for cleaning, drying and oiling after every use. A can should remain in place during training and deployment. The weapon should be sighted in with the can in place, as the weapon’s point of impact will be different without that added muzzle weight. A weapon should not be fired without either a muzzle brake, a flash hider or a suppressor screwed on to 1/2-28 threads at the muzzle, as those threads have been known to expand without the support those devices offer to the thin, threaded area. The muzzle crown may expand, and the devices won’t screw back on later. This is not a common problem, but it occasionally does occur.

A properly designed and mounted suppressor typically enhances accuracy. The weight of the can will stabilize barrel movement. The reduction of recoil and report make the weapon much more comfortable to shoot. While these little rifles are primarily used at close range, they are also capable of being very accurate at longer distances. With a proper sight and a skilled marksman headshots are definitely viable at 100 yards. Iron sights are normally adequate on the M16 carbine. They are compact, durable and battle proven. An attached tactical flashlight with a pressure switch on the forearm is a useful accessory, although it certainly can reveal one’s position.

| This article first appeared in Small Arms Review V4N5 (February 2001) |