By Paul Evancoe

Many believe a repeating firearm’s reliability is based upon its operating system. While this assumption is true, the root cause of most weapons’ malfunctions center upon a failure to properly feed live rounds, or properly eject spent brass. A clean properly lubricated operating system is important, but the vast majority of malfunctions can be ultimately attributed to some form of magazine failure. This is true for all repeating actions from manually operated bolt and lever actions, to self-loading semi-automatic and automatic actions. Jams, stovepipes and ejection failures top the malfunction list; but first, some design success stories.

Mikhail Kalashnikov developed the AK-47 in the 1940s for the Soviet Red Army. Since then, over 75 million AKs have been made. Its short stoke gas piston operating system is fed by a robust double stack 30 round all steel magazine. The AK-47 is not a precision made elegant weapon, but it’s cheap to manufacture and is perhaps the most reliable and proliferate assault rifle ever made.

In 1948 Major Uziel Gal developed his easy and cheap method to manufacture a highly reliable Uzi 9mm submachine gun that employs a simple blowback operating system fed by a sturdy 25- or 32- round double stack magazine. More than 10 million Uzi sub-guns have since been manufactured. Uziel Gal’s design philosophy, according to him, was to first design the magazine around a particular round of choice (he chose the 9mm Parabellum). Then design the gun around the magazine. This, he insisted, “provides for the utmost performance reliability.”

This same design philosophy was used on a grander scale in the 1960s in the USAF’s wildly successful close air support A-10 Warthog.

The operational requirement was for an aircraft that could successfully take out tanks and armored vehicles, and provide close air support for ground troop operations, e.g., stop the Soviet advance across the “Plains of Europe.” This requirement translated to a comparatively low cost aircraft with high target lethality and superior survivability against ground fire. The desig ners began by selecting the armor-killing gun; a single 30 mm GAU-8/A seven-barrel Gatling gun. Then they built a survivable aircraft around the gun, with a unique titanium bathtub-like armor shield surrounding the lower cockpit to protect the pilot from ground fire.

Double Stack

Their design choice of materials and functional simplicity provides for a highly reliable combat pistol that feeds flawlessly when shooting in any attitude (vertically up or down, or on either side ejection port up or down, with or without the additional weight of a sound suppressor).

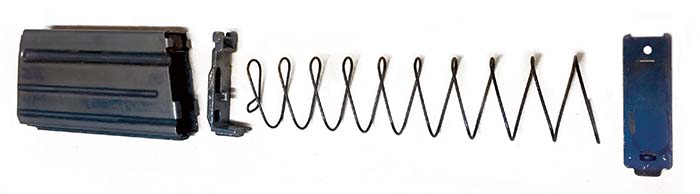

More recently, this design philosophy was employed by FN when they designed their polymer lower and stainless steel upper FNP-45 (now the FNX-45). The pistol’s high capacity 45 ACP double stack stainless steel magazines

contain beautifully designed followers lifted by a coiled wire spring.

Magazines Are Fundamental to Operating System Reliability

There are several very important firearm design features that should be fully understood before making any firearms purchase. The single most important feature, and also most often overlooked, is the magazine. Magazines come in a variety of forms. The classic removable box-type design used for most modern assault rifles and pistols is most common. Additionally, there are tubular magazines mounted beneath the barrel (or inside the stock) like many lever action and pump action rifles and shotguns employ, and internal small capacity magazines commonly used on many bolt action hunting rifles. There are also rotary magazines and externally mounted high capacity drum and box magazines that contain linked ammunition belts used on most all machineguns. Linked ammunition magazines and their associated feed conduit will not be addressed in this discussion.

Regardless of design, magazines provide for ammunition storage and share a common operating design in all repeating actions by presenting the next round to the bolt’s forward stroke for chambering. Magazines may appear to possess little sophistication, and indeed some do not. After all, in most cases they’re little more than a spring, a follower, a floor plate and a plastic or fabricated sheet metal container; pretty basic engineering – right?

The truth is, most magazines are far more sophisticated. Here’s the operating process in simple terms. When the gun is fired and the spent round is ejected on the bolt’s back stroke, the magazine spring pushes the follower upward and the next round is presented at exactly the right height and angle of attack so the bolt’s forward stroke can skim the round off the top of the stack and carry (feed) it into the gun’s chamber. Seems simple enough – what can go wrong?

Most of us would like to think that factory magazines are built to a precision specification designed for each particular gun model, and that magazines are fully interchangeable within the same gun model. While that is fundamentally true, not all magazines are created equal. Different manufacturers’ quality control their products to different plus/minus tolerances. For example, the gun’s bolt and/or slide is fitted to the upper and/or receiver along with the trigger group. The barrel is fitted to the gun with particular attention to head space (gap between the bolt face and chamber) when the gun is loaded, in-battery and ready to fire. Attention to detail is given to material construction, tolerances and finish on these parts, because they must work together smoothly if the gun is to have any operating system reliability.

This translates to a variety of different parts with different tolerances, some plus, some minus, being combined to work within an overall design specification. It also means for example, if several plus tolerance parts are combined with other plus tolerance parts this can mean a tight fit. The reverse is true for the combination of minus parts resulting in a loose fit. As long as the overall factory tolerance specification is met, the combination should reliably function as designed. However, aftermarket parts are not factory parts and don’t undergo factory quality assurance, and that is most often a problem. This is especially true in aftermarket magazines.

Even with reasonable design and manufacturing quality assurance of critical gun parts, expensive guns still often experience out of the box feed, extraction and ejection malfunctions, leaving the shooter scratching his head and wondering why. Not generally understood, the reason is usually the magazine. Unfortunately, far less manufacturing attention is paid to magazine design, material construction, and fit.

Let’s look at the dynamics at work inside a magazine. The follower is pushed upward by the magazine spring, elevating the cartridge stack holding it in tension against the magazine’s feed lips. The spring must have enough consistent tension to overcome both the weight of the cartridge stack and the drag (friction) of the follower as it climbs the magazine walls. It must also do this in a proper time to present the cartridge for feeding when needed- if it’s dragging a little, the bolt might be coming forward and miss the feed. The greater the capacity of the magazine, the “more powerful” the spring must be to do its job. Then add some grit inside the magazine or rusty or corroded inside walls and you have a feed malfunction. The root cause is because the spring can no longer reliably elevate the follower and elevate/hold the cartridge stack in the ready position against the feed lips.

In order to understand what to look for we need to take a close look at the variables involved, beginning with a common box-type removable magazine. Many of us believe if a 20 round magazine is good, then a 30 round is better, so a 40 round magazine is better still. Nothing could be farther from the truth. In reality, the higher the magazine capacity, the greater chance of malfunction. Why? With more rounds comes more weight in the cartridge stack, more drag/friction for the magazine spring to overcome, more cartridge alignment problems, etc.

Box-type magazines are installed into the magazine well by pushing them (or jamming them) upward until the magazine catch engages a hole or slot cut into the magazine body for that purpose. This catch holds the magazine from being inserted too far and also holds it in place until the magazine release button is pushed. This releases the magazine, allowing it to either fall from the gun under its own weight or pulled from the gun with a free hand.

In most gun designs, the magazine catch is insufficiently robust. It is usually a pressed or sintered part (not precision machined and tempered) that uses a small spring to keep it extended (locked) into the magazine catch hole/slot. In most designs, little importance is placed on the robustness of the magazine catch’s axel, spring or material construction. Sand can easily foul the catch’s proper locking movement, the spring can fatigue or break, and the catch itself can wear down. This results in catch failure and a gun that will not reliably hold the weight of a loaded magazine. The higher the magazine capacity, the greater the weight that small catch must hold.

Ambidextrous magazine releases require special attention because they are often poorly designed and not robust enough to hold the weight of a loaded 30 or 40 round magazine in the magazine well. Consider the weight of a 30 or 40 round magazine hanging on that small catch. Now add some tactical scenario rough treatment like banging the installed magazine down on a hard surface. Forces are applied in sheer and that small catch is exposed to tremendous loads. Obviously, if you’re a fair weather shooter who doesn’t expose his gun to combat-like operating extremes, reliability may not mean much. But if your gun’s reliability means life and death, pay attention. You may want to upgrade your magazine catch and spring.

Improper Magazine Fit is a Feed Malfunction Root Cause

Your magazines’ installed height is critically important. When the magazine installs too low, the round is presented too low to the bolt face on the forward stroke and at the wrong angle. This situation many times causes stove pipe-type malfunctions on the forward stroke, or being missed by the bolt altogether (the bolt passes above the cartridge missing it on the forward stroke).

Again a loose fitting magazine can be the result of wear or it’s just out of spec. A magazine’s installed height is one of the most important factors in reliability. Magazines that don’t feed properly should be discarded whether they’re out of the box new or well used.

A second thing to look for is fully loaded magazines that fit too tightly in the magazine well. This is especially true in pistols. Tight fit results from either poor magazine material construction, sloppy tolerances in manufacturing, or from magazine swell. Magazine swell is often the result of magazine walls constructed from plastic or sheet metal that is too flimsy and flexible. The symptom to watch for is when the cartridges of a fully loaded magazine push the magazine walls outward, swelling it to a tight fit against the gun’s magazine well. This is a malfunction waiting to happen.

Also, the magazines themselves can be made flimsily to the point that the magazine catch doesn’t adequately engage the slot intended for it, or the slot becomes easily dented or worn as a result of poor magazine material construction. Many (not all) aluminum and plastic magazines are notorious for this type of failure. There are some exceptionally reliable polymer magazines on the market. For example, P-Mag makes an extremely reliable polymer magazine as does Glock with their unique polymer-sheathed metal body magazines.

Follower design, material construction and alignment with the magazine walls is another critical magazine reliability element. Think of the follower in terms of it being an elevator that lifts the cartridge column upward. Followers come in many forms, polymer, composite and metal. Some are molded, some are cast and some are fabricated from sheet metal. All serve the same function and that is to provide a stable base on which the cartridge stack rests. The magazine’s spring beneath the follower applies tensioned pressure to consistently push up the cartridge stack against the magazine lips, presenting the next cartridge to the bolt on its forward stroke. The spring tension pushing against the follower must not be too powerful or the cartridges won’t feed. It cannot be too weak or the rounds will fall out of the magazine when the action is open.

Regularly clean and lubricate the inside of your magazines. Where design permits, disassemble your magazines by removing the floor plate (Only if designed for removal – many floor plates are permanently attached). Pull the spring and follower out and clean all the parts as well as the inside of the magazine. If you find rust or corrosion that cannot be removed, throw the magazine away. Lightly lubricate the parts and ensure proper reassembly. In magazines that have welded floor plates that can’t be removed, soak the magazine in gun cleaning solvent. Blow it out with compressed air. Apply a dry lubricant to the internal walls, spring and follower. Dry lube works best because sand and dirt usually stick to a wet lubricant. After cleaning, compress the follower using your finger or dowel. Ensure it functions properly and doesn’t scrape or drag along its travel. Ensure the floor plate is engaged so your magazine won’t inadvertently come apart, spilling its rounds in the middle of a gunfight.

Last, carefully inspect the magazine’s feed lips for alignment. The feed lips can often become bent and misaligned from dropping the empty magazine on the ground during a tactical reload of your gun. Misaligned feed lips will result in feed malfunctions. Damaged feed lips can sometime be realigned by skillfully bending them back into tolerance. However, that is usually a trial and error (hit or miss) process not recommended for magazines intended for tactical use. Also inspect the magazine body for cracks that can affect structural integrity. Even small cracks can cause malfunctions or lead to them. Discard those magazines.

Most pump actions and lever actions use a tubular magazine that is mounted beneath the barrel or contained within the stock. Tubular magazines suffer some of the same internal malfunction issues inherent to box magazines, but have a distinctly different feed process than box magazines. The internal cleanliness of a tubular magazine is extremely important to its reliability. Internal dirt and rust both inside the magazine tube and inside the follower rod containing the follower spring, are usually the show stoppers. The tubular magazine housing along with the follower rod and spring should both be internally cleaned and lubricated with a dry lubricant. This will reduce cartridge drag when fully loaded and is especially important to reliable feed when shooting vertically – up or down.

A second critically important feature on guns with tubular magazines is the feed mechanism located beneath the bolt that lifts/elevates a round from the tubular magazine upward, presenting it at precisely the right angle of attack to the bolt’s forward stroke for chambering. That feed mechanism, in cheaper guns is many times poorly constructed (sometimes from polymer materials). Wear and dirt will cause the feed mechanism to become sloppy (out of tolerance) or prevent it from full travel resulting improper feed.

What about drum magazines? Guns that are factory-designed for drum magazines like the Thompson sub-machinegun, have robust magazine catches intended to hold the added weight of a loaded drum magazine. Using an aftermarket drum magazine in an AR-style gun or pistol without replacing the gun’s magazine catch with a significantly more robust version, is suicidal in a gunfight. The same goes for extra high capacity magazines that extend well beneath the magazine well. You’re asking for feed and ejection malfunctions for all the reasons previously discussed.

Finally, the magazine’s spring is a critical element of reliability for all magazines no matter what type. Early magazine designs employed leaf-style flat springs or single strand spring wire that when kept compressed in a full magazine for months on end would not reliably spring back (and reliably feed the contents of the entire magazine). This is known as “spring memory.” Early AR magazines (Vietnam vintage) and Model 1911 pistol magazines were like that. Magazines with flat springs or single strand spring wire required unloading about every two weeks with a couple of weeks “rest” before reloading so the spring wouldn’t “remember” its compression. Many shooters still abide by that today and religiously rotate their loaded and unloaded ready magazines to prevent magazine compression spring memory.

However, most quality magazine springs today are made from multi-strand twisted steel spring wire alloyed specifically for that purpose. They don’t have a memory and can remain loaded for years without spring memory becoming a reliability factor. It is nevertheless important to ensure the springs in your magazines are of the quality variety. Check them and be sure. Magazine springs and their unique metallurgy will be the topic of a future article.

So now you have it. Use only quality factory design spec magazines. Check each magazine for proper installed height. Ensure the magazine spring and follower align the rounds with the feed lips. Ensure the feed lips are undamaged and aligned. Inspect the magazine body for cracks. Keep the inside of the magazine clean and lubricated. Ensure the floor plate is firmly in place. Inspect the gun’s magazine release mechanism for wear and proper operation. Keep it clean and lubricated. Discard magazines that are ill fitting, damaged, or that continually cause gun malfunction. Read your magazines.

| This article first appeared in Small Arms Review V20N10 (December 2016) |