By Christopher Bartocci

Ever since the change over from the 7.62x51mm to the current 5.56x45mm there has been controversy between two fundamental schools of thought on what a military cartridge should be. The United States military can be summed up in one word: tradition. In the 1960s, that tradition clouded the vision that a new dawn of small arms development in both concept, mechanics and ammunition had come. Still entrenched in the “one shot, one kill” mentality, our soldiers were sent into combat in Vietnam with the M14 which many considered to be an inferior weapon to the AK47 assault rifle that the enemy used. The enemy were able to lay controlled large volume of automatic fire on positions which, in a meeting engagement, will win you a fight. Our soldiers were equipped with a heavy recoil rifle that was impossible to control on fully-automatic. The accuracy was of no use because the enemy could not be seen.

With much trepidation, the military adopted the AR-15 rifle destined to become the M16/M16A1. A new age of small caliber high velocity cartridges gave way to providing an individual soldier with firepower he had never had before. The 5.56x45mm cartridge utilizing a .224 diameter 55-grain full metal jacketed bullet proved to be a great asset to the American fighting man with the ability to have a lightweight rifle that was completely controllable on fully-automatic fire and the soldier could carry more than twice the combat load with an M16 than he could with the heavy M14 rifle.

The Third Generation M16A2 and M855 Ball

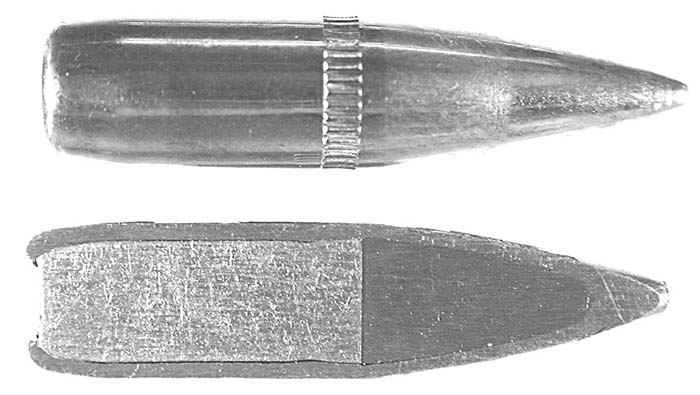

With the product improvements of the M16A2 the weapon system was enhanced. Due to the heavier 62-grain bullet, 1 turn in 7 inch rifling twist and new fully adjustable rear sight, both penetration and long range accuracy were enhanced. However, the culprit of the future problems with ammunition terminal performance would come from the ammunition, the M855 Ball.

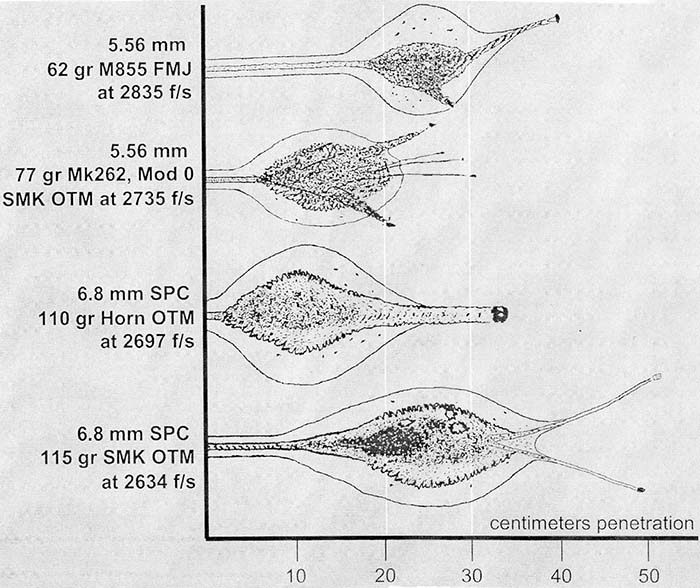

The M855 Ball is a three piece bullet consisting of a copper jacket, lead plug and a steel penetrator core in the tip. This bullet was designed for a machine gun, not a rifle. With the onset of the Global War on Terrorism, terminal deficiencies were found using M855 Ball, particularly in M4 carbines, when striking thin, malnourished, Taliban and Iraqi soldiers. There was a serious inconsistency in at what point the bullet would yaw and splinter. Some lots of ammunition would penetrate only slightly within inches and yaw and splinter. Others would go straight through and never yaw nor splinter. This caused serous knockdown problems particularly with the decreased velocity of 14.5 inch carbine barrel.

A solution put forth by the United States Special Operations Command (SOCOM) was the creation of a new and improved 5.56x45mm cartridge that would increase long range accuracy and terminal performance with consistency. Accuracy is seriously degraded in the M16A2/A4/M4 due to the inherent characteristics of the M855 bullet. The penetrator core degrades accuracy and if not manufactured properly, the center of gravity will be off causing the bullet to become a “flyer.” Additionally, in the area of terminal performance, there was no consistency from lot to lot on what exactly it would do upon hitting a human target.

The answer was the Mk 262 MOD 1 cartridge that SOCOM adopted. This is a Sierra 77-grain open tip match bullet loaded by Black Hills. This is undoubtedly the most effective 5.56x45mm military cartridge in the world manufactured to match grade specifications with combat reliability. The long range accuracy was drastically increased and its terminal performance enhanced. This new projectile works well regardless of the type of target and performs considerably better on human targets in all known distances and conditions. This round is used almost exclusively by SOCOM operators in their M4A1 carbines and Mk12 rifles. This solution satisfied most of the SOCOM operators: except for one.

The 6.8x43mm REM SPC

The 5th Special Forces, particularly MSG Steve Holland, felt that there was still room for improvement. The concept was not original. The U.S. military experimented with the possibility of the 6mm caliber projectile being the ideal compromise of accuracy, range and terminal performance. In the late 1970s the concept was abandoned in favor of the 5.56x45mm battle rifle.

With the assistance of the U.S. Army Marksmanship Unit, Holland came up with a concept for a 6mm cartridge that could be fired in the M4 platform. The starting point was the .30 Remington cartridge which is merely a rimless .30-30 Win. round. It was trimmed and resized to accept a 6.8mm projectile. This concept, along with the hand-loaded experimental ammunition and CAD drawings went to Remington Arms. Remington wanted to aid in the Global War on Terrorism so they took on the task of developing the ammunition.

The 6.8mm REM SPC cartridge has been mostly a myth for the last few years due to the fact it has been developed quietly and kept proprietary. No ammunition has been made as of this writing in large quantities due to the fact the ammunition is being perfected before it will be shipped. Remington has reported three small runs of ammunition including ball and match grade ammunition. Hornady has also produced some loads in this new caliber.

The Firearms

Prototype rifles were manufactured by Precision Reflex, Inc. (PRI). Dave Dunlap assembled upper receivers with free floating handguards or A.R.M.S., Inc. SIR systems and the OPSINC silencer and muzzle break. Dunlap also was charged with designing the magazine which is different from the standard 5.56x45mm magazine. Currently, PRI has been the only producer of 6.8x43mm Rem SPC magazines. PRI also produces complete upper receivers chambered in the 6.8x43mm Rem SPC cartridge.

The Barrett M648

At the 2004 SHOT Show, Ronnie Barrett unveiled a new product line: his M648. This company, dedicated to .50 BMG caliber specialized weapons, introduced the first production 6.8x43mm Rem SPC firearm and has taken the lead on this project. While the cartridge is still technically under development (to be more correct would be to say “tweaked”), Barrett has teamed up with Peter Forras to work with Remington to optimize the weapon and cartridge. Forras has spent much time down at Remington working with them to perfect the 6.8x43mm cartridge.

The rifle has been based on the standard M16-platform. Barrett offers the rifle in both commercial and law enforcement/military configurations. The “bells and whistles” are the same for both versions, the only real difference is the use of selective fire, flash suppressors, bayonet lugs and telescopic stock on the law enforcement/military models.

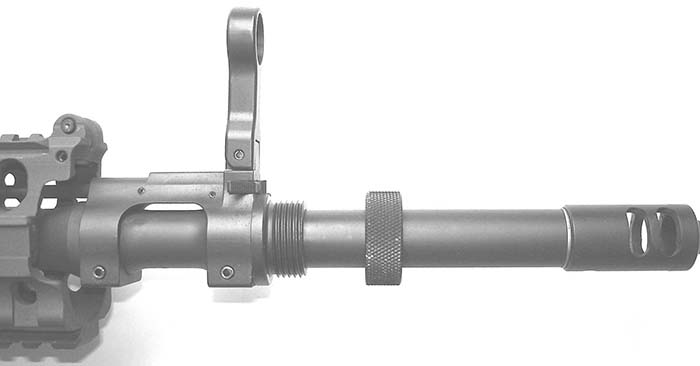

The weapon as offered uses a mid-length gas system developed by Mark Westrom of ArmaLite, Inc. This mid length gas system changes the location of the gas port by placing it further forward than the carbine and slightly behind the rifle. This gives two major advantages: reliability and durability. By putting more distance between the bolt carrier and gas port, lower port pressures are created resulting in the bolt assembly’s velocity being slower. This increases reliability in extraction as well as extending the life of the bolt and some of the trigger components.

The barrel is manufactured by Fred Fedderson. This 1 turn in 10 inch twist barrel is chrome plated and is currently available in 16 inch length only. Barrett has plans on offering 12 and 20 inch barrels in the near future. The commercial version has a muzzle check similar to the one used by ArmaLite, Inc. The law enforcement/military versions use the standard M16-style muzzle break/compensator

The M648 gas block utilizes a folding front sight assembly. This assembly was designed by Barrett. On the law enforcement/military version, there is a threaded collet on the edge of the gas bock to install the silencer.

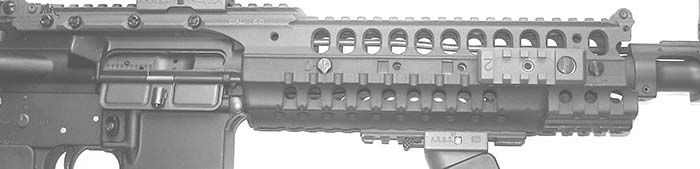

The Mid-Length SIR System

The A.R.M.S. Inc. SIR (Selective Integrated Rail) system developed by Richard Swan is the solution for many problems associated with military use of this type of weapon system. The SIR system is a free-floating handguard assembly that attaches to the carrying handle by a sleeve that goes on top of the rail (thus protecting it) as well as directly to the barrel nut. This give an extended top rail that runs the entire length of the upper receiver to the front sight assembly. There are four Mil-Std 1913 rails that enable optics, laser, flashlights and whatever other accessories that may be needed for the rifle with no effect on the barrel and its performance.

Free floating a military weapon has many benefits. First would be accuracy. With nothing impeding on the harmonics of the barrel, better uniform accuracy is achieved. Additionally, the barrel remains cooler as there is significantly better air circulation enabling the weapon to fire longer on full automatic fire. Another benefit, particularly with a hot barrel, pulling down on a vertical fore grip will not cause the barrel to bend or droop. The SIR system may also have a M203 grenade launcher attached to it. All the current models of the M648 feature the A.R.M.S. Inc. SIR system as well as the ARMS #40 L emergency flip-up backup sight.

The Bolt

The bolt carrier is standard M16/AR-15. The difference lies in the bolt itself. The bolt was designed by Chris Barrett and is manufactured by Lewis Machine & Tool (LMT). The bolt uses the trademark dual extractor spring “lobster tail” extractor manufactured by LMT as it is more durable and reliable. The bolt has other similarities to the LMT Enhanced bolt but Barrett made some changes in materials and specifications specifically for the M648. The bolt has a nickel plating on it.

Configurations

The M648 comes as a full weapon with fixed rifle stock as well as selective fire carbine lower receiver with the telescopic buttstock. The system is also sold as an upgrade or a conversion kit which will include the entire upper receiver assembly and magazine. The conversions can be obtained with either selective fire bolt carriers or semiautomatic only. It should be noted that when putting a conversion on a standard selective fire carbine lower receiver, the “H” buffer should be used. This is the buffer with two steel weights and one tungsten. If the standard three steel weight buffer is used the carbine may experience bolt carrier bounce resulting in light strikes on full automatic. This is not an issue with the full length rifle selective fire lower receiver. Semiautomatic guns can use either due to the bolt group will have sufficient time to lock before the next shot is fired. There has been some discussion about Barrett eventually coming out with a piston driven mechanism for this weapon system.

Shooting Impressions

The rifle received for testing was a law enforcement/military upper receiver with a standard semiautomatic only lower receiver. The author’s own Colt M4 full automatic carbine lower was used for full automatic testing. The semi-automatic only lower receiver was equipped with an LMT two-stage match grade trigger. The optics used were the M68 Aim Point Comp II, EOTech holographic sight as well as the standard backup sights. Approximately 700 rounds were fired in total in both semiautomatic for accuracy as well as fully automatic for functionality. The magazine used was a PRI made 28-round steel magazine. The ammunition was manufactured by Remington.

Fully-automatic tests were conducted in close quarter battle conditions. Targets ranged from 5 to 25 meters. The cyclic rate was about the same as the standard M4 carbine and recoil was really not that much more. There was no problem controlling the weapon. The EOTech sight made shooting easier allowing both eyes to remain open increasing speed and accuracy. By adjusting the brightness of the sight, it was useful for both close tactical work as well as short range sniping.

Conclusions

The 6.8mm Rem SPC is without a doubt an improvement over the existing 5.56x45mm for military use. But the question is, how much better? The cartridge unfortunately has a very steep uphill battle ahead of it once the military community gets a hold of it. The weapon itself is not an issue. The M16-based design is well proven. But in order for SOCOM in particular to adopt such a cartridge for use will be a gigantic undertaking. First and foremost it has to be more than better, it will have to be drastically better and offer a large advantage. Second, and perhaps the most critical, will be logistics. The cartridge will be at best used by SOCOM operators and them alone. From a logistical standpoint, adding a new cartridge into inventory, in particular one nobody else in the service uses, can cause serious problems. Once SOCOM operators are deployed they become part of the unit they are assigned and along with that goes their supply. Having non-compatible ammunition can put the operators at risk given they do not have re-supply specific to them.

The Barrett M648 and 6.8x43mm Rem SPC ammunition performed flawlessly and accurately. Barrett has not been too quick to go into production due to the fact they have waited until the development of the rifle and ammunition was completed insuring their customers get a final production weapon and not a semi-prototype. As of this writing, after more than three years of advertising and manufacturing of barrels to fire this new cartridge, the ammunition has yet to be completed and put into full production. This weapon and cartridge will undoubtedly find a following in law enforcement and commercial shooters and competitors. As far as the military use of this weapons system, only time will tell.

| This article first appeared in Small Arms Review V10N2 (November 2006) |