By Anthony Dee

Back in the early 1980’s I had the opportunity to become involved in the testing of an innovative sighting system developed for the M-16. This new system was developed by Eastman Kodak Company. In the writing of this article it is not my intent to compromise any confidentiality agreements, therefore I will intentionally remain quite vague in my account. I was working in the capacity of a liaison between Kodak and an undisclosed agency that Kodak had approached for assistance. I was employed by that agency and was instructed to assist with the testing of a new scope that was being developed for sale to military agencies.

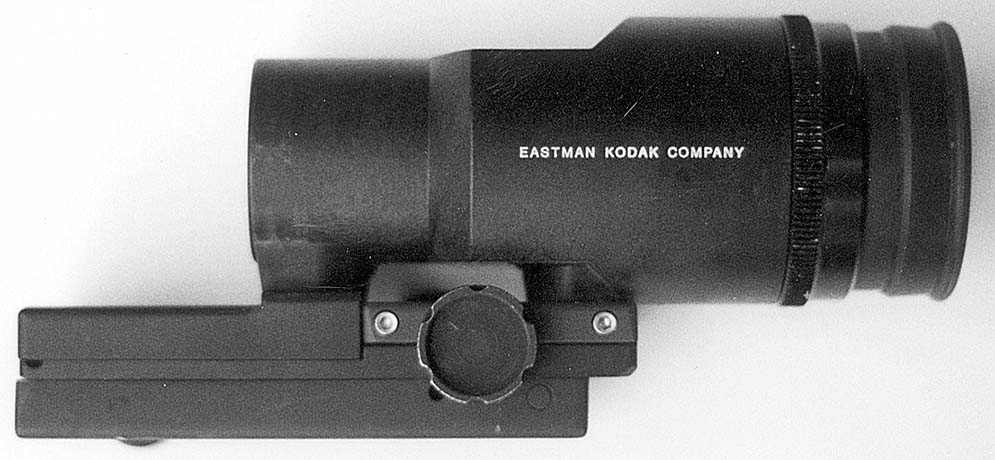

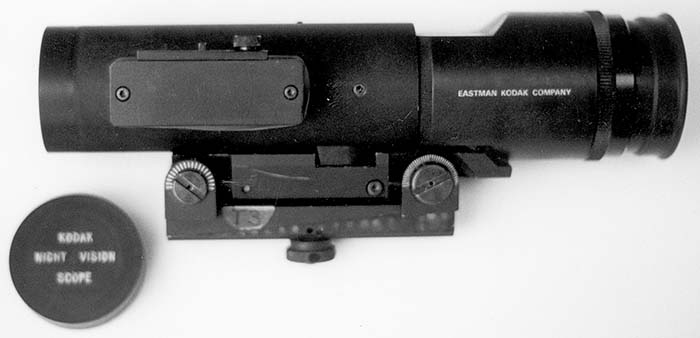

A prototype had already been built and was ready for preliminary testing when I became involved. Kodak had developed an insert-molding technique that allowed the imbedding of a pressed glass lens that was not edge trued, into the plastic body of a riflescope. This was a very advanced design and could dramatically lower the cost of quality military optics. The proper positioning of the lenses and prisms was critical to the success of this project and Kodak seemed to have perfected this difficult technique. This new scope was to have a Tritium illuminated reticle and also be fitted with a slide-on night vision adapter. It sounded like a very ambitious project that had almost everything going for it. I was very anxious to see this new scope and begin testing.

The system was never adopted by any military branch and was found to be inadequate in several areas during final field testing. I can attribute this to the simple fact that the majority of the designers and engineers working on this project had almost no firearms experience at all. It is not my purpose to disparage the company or its personnel, but I was amazed at the lack of basic firearm knowledge displayed by the staff. An example of this was apparent at the first test.

I was met at the range by the project manager and several engineers. At that time I was shown a short plastic scope that was mounted on a base that fit into the carry handle of the M-16 by means of a thumbscrew. The one thing that struck me as odd was that neither the scope or mount had any means of adjustment for windage or elevation. When I questioned the project manager about this he assured me that the scope was pre-sighted for trajectory along the bore of the rifle and that any adjustment was unnecessary. I was skeptical at best and began to explain the several variables involved in the mounting and sighting of a riflescope. I was assured that these variables were all taken into consideration and the testing proceeded. The scope was mounted on a rifle and the first tests were conducted to measure the forces recoil would have on the scope. These tests ended satisfactorily but not a single round of ammunition was fired at a target. Weeks later another set of tests were ordered to test the scope for accuracy. As you can imagine, this did not work out very well at all. Some of the engineers could not believe that the scope didn’t shoot the “X” ring out of the target as all of their calculations had predicted. It was then decided that a new mounting system had to be designed that incorporated adjustments for windage and elevation.

A.R.M.S., a well known scope-mount manufacturer was contracted to manufacture several prototype mounts that had thumbwheel adjustments for windage and elevation. These thumbwheels had click type detents and were located on both sides of the mount. The windage knob on one side and the elevation on the other. Several months later after the mounts were completed another round of tests were conducted. These tests were again not very successful as the click adjustments were far too coarse. One click could move the point of impact about twelve inches at one hundred yards. This was understandably unacceptable and revisions were ordered. By this time an alternative mounting system was also being considered.

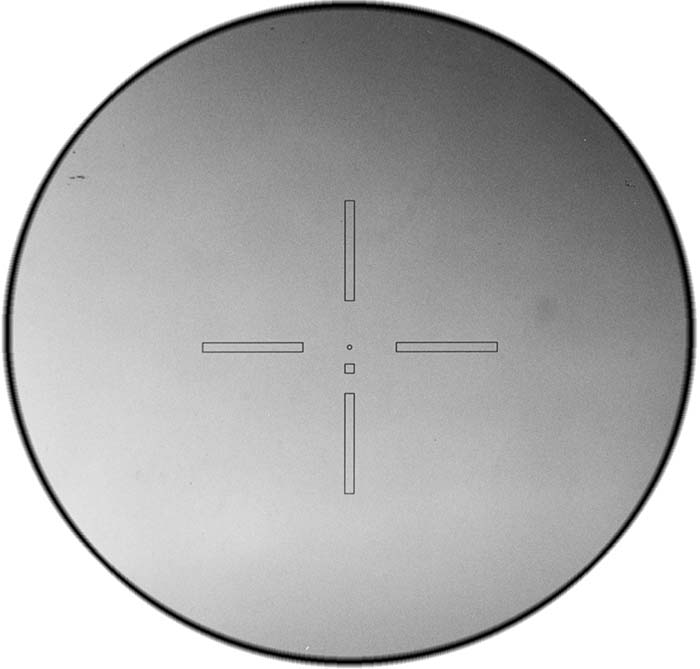

I provided the project manager with some old type Bausch & Lomb mounts. These mounts had external adjustments for windage and elevation and had proven themselves reliable in the old Bausch & Lomb Balvar, Balfor & Baltur Riflescopes of the 1950’s and 1960’s. Like the Kodak scope, the Bausch & Lomb scopes also lacked any internal adjustment. A prototype mount was built and worked quite well. The scope could be adjusted finely and hold zero reliably. About this time a prototype of the Night Vision adapter was completed. It utilized a second generation intensifier tube that was activated by a lithium power source. The mounting system and focusing adjustments were not perfected at this point in time, but the system did work. There were at least two types of reticles developed for this system and a photo of the final design is shown. Some of the prototype scopes did not have the tritium lit reticles and the first ones had very crude hand etched reticles. There were two types of the revised A.R.M.S. mounts built. One fit into the carry handle of the standard upper receiver. The other was manufactured with a “Weaver” type base made to fit on the then newer type “Flat Top” type upper receiver. A padded O.D. colored nylon case was designed for the carrying of the scope on a belt. A final prototype design was submitted for testing, but was found to be unacceptable for service. At this time the project was disbanded and the personnel were reassigned.

I felt that this system had a great deal of potential but in my opinion the project was doomed from the onset. The main reason was the dismal lack of basic firearms knowledge of the personnel involved. If the scope had been originally designed with internal adjustments it would have had a far better chance of being successful. It is incomprehensible that a multi-million dollar project of this magnitude would be initiated without the input of several “Reasonably Knowledgeable Individuals” or (RKI’s) as we know them at SAR.

A few of the remaining prototype scopes and mounts have found their way into the hands of such a person. These scopes are unique in their design and are a rare piece of firearms history. If anyone is interested in obtaining one for their personal collection you can contact me through SAR and I will put you in contact. Please, serious inquiries only.

| This article first appeared in Small Arms Review V4N5 (February 2001) |