The first production model of the AK-rifle. The receiver was made of pressed sheet metal.

By Frank Iannamico

AK Photographs Courtesy of the U.S. Marine Corps National Museum

Shortly after World War II began, the belligerents involved soon discovered that they needed to increase production of weapons to arm their expanding armies and replace those arms damaged or lost in the field. The problem they all faced were the lack of machine tools and men to operate them. There was also a shortage of the raw materials needed to fabricate weapons, with the aircraft and ship building factories having priority. The solution to the problem was first solved by the Germans who pioneered an entirely new method of manufacturing small arms using inexpensive carbon steel stampings, assembled with rivets and welding.

The most successful German weapons fabricated from sheet metal were the MP40 submachine gun and the MG42 machine gun. The ordnance establishments of the world took notice and soon introduced their own sheet-metal weapons. The British had their Sten, the United States M3 and M3A1 “grease guns” and the Soviets fielded their PPSh and PPS43 submachine guns. Despite having a rather crude appearance, the sheet metal weapons were proven to be every bit as rugged and reliable as their labor-intensive counterparts.

Every gun designer studies previous designs to learn what works and what doesn’t. Mikhail Kalashnikov was particularly impressed with the simple, all-metal stamped steel construction of the 7.62x25mm Pistolet Pulemet Sudayeva, PPS43. Kalashnikov realized the pressed steel construction was the way future small arms would be made. Three basic principles would be followed in all of Kalashnikov’s designs: simple, reliable, and easily manufactured. Accuracy requirements in the Warsaw Pact, though important, were not as critical as the requirements of the NATO member countries.

The very first production AK rifles were manufactured with stamped sheet metal receivers before the more commonly known milled receiver model appeared. There was no designation change regardless of the receiver type; they were simply called Avtomat Kalashnikova rifles. The designations Type 1, Type 2 and Type 3 have been widely accepted by historians and enthusiasts as a means in which to identify particular AK models. However, these are not official nomenclatures. Despite numerous detail differences, there was no designation change to any AK rifles until the AKM model was introduced in 1959.

The First Generation Russian AK

Although there were a substantial number of prototypes and experimental versions of the AK rifle, the very first production models emerged during 1948 from the Izhevsk Motor Plant, factory 524. Other armament plants supplied some of the parts and components for assembly of the weapon. During 1949, production was transferred to the Izhmash factory 74. (Dan’s note: General Kalashnikov was in Serbia at the Zastava factory at Kragujevac, and he was out to dinner with three of us Americans- weapons designer Charlie Rostocil, Dr. Philip H. Dater of Gemtech, and myself. Charlie kept on the subject of “The first AK,” because the General had always held that his first model worked, and was the “First AK.” Finally, the General admitted there were 5 or 6 prototypes, but “The first AK was the one that worked perfectly, the others were just attempts.”

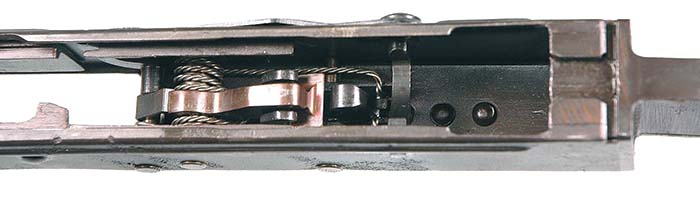

The first production AK rifles, chambered for the intermediate-range 7.62x39mm cartridge, were produced with receivers fabricated from a 1.3mm thick U shaped sheet metal stamping. Located at the front of the receiver was a machined block of steel that served as the barrel trunnion. The trunnion was secured in place by eight rivets; four on each side of the receiver. The inside of the trunnion block was threaded for attaching the barrel to the receiver assembly. This also included locking shoulders for the breech bolt, short sections of the bolt guide rails and the ejector. A second steel block was positioned just forward of the barrel’s breech. This component housed the rear sight assembly, had a flange for the gas tube, and the components for locking the gas tube in place. The lower part of the block encircled the barrel and had a lateral solid steel cross pin installed to prevent the rear sight base and barrel from loosening.

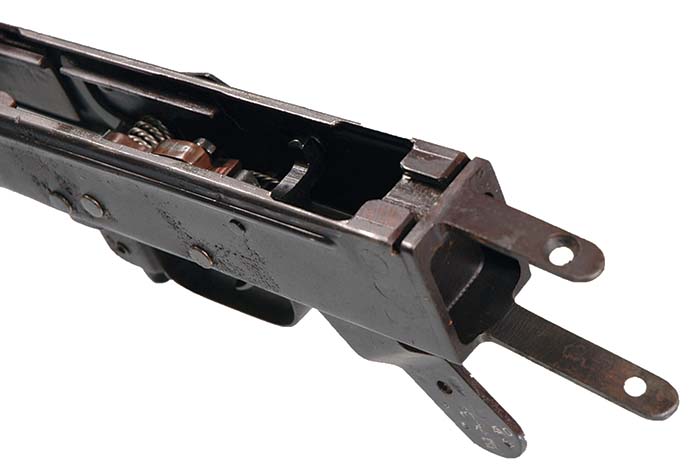

At the back end of the receiver was another steel trunnion that had two tangs extending from it to secure the buttstock, and a groove at the top to contain the guide rod of the recoil spring assembly. This piece was secured with three long rivets, which extended completely through both sides of the receiver.

A similar assembly, without the extended buttstock tangs, was used for the underfolding stock model. All of these components served as “bulkheads” providing the sheet metal receiver with strength and rigidity. The upper edges of the sheet metal receiver were bent inward at a 90-degree angle, providing rails for the bolt carrier to ride on. Two additional bolt guide rails were riveted to the inside of the receiver, just forward of the trigger guard. A horizontal rib pressed into each side of the receiver at the top that served as a ledge to support the receiver top cover and add strength to the receiver. The top cover was smooth and made of heavy gauge stamped steel that was 1.6mm thick (.063-inches).

On the underside of the receiver was a stamped steel trigger guard assembly. At the front of the trigger guard was a channel to house the magazine catch and spring; at the rear of the trigger guard was a long sheet metal tab that extended down from the receiver for attaching the pistol grip. The pistol grip of the first production model was unique in that it had two wooden or plastic side panels secured by a lateral screw and threaded insert. The trigger guard frame assembly was attached to the receiver floor by five rivets.

The fire control components were held in place and rotated on steel axis pins placed laterally through the sides of the receiver. The pins were secured in place by the long trip sear spring, which rested in grooves located on the left end of the axis pin-heads. The double-hook trigger, hammer, and disconnector were a design that was similar to those used on the later milled receiver AK rifles. The rod of the gas piston had flutes machined into its shaft to reduce its weight and the gas piston assembly was chromium-plated to resist the effects of corrosive ammunition. The bolt carrier and bolt were left in the white. The sheet metal steel gas tube ribs had four round gas relief holes placed horizontally along the length of the tube on each side at the 3 o’clock and 9 o’clock positions. The recoil spring assembly had two telescoping hollow metal tubes. The spring was installed over the tubes and was secured by a steel circular retainer cap that was slotted. With the spring compressed, the cap was slid onto a groove cut into the front guide rod holding the assembly together. The mode of fire-safety lever had only one tang located at the lower edge. The tang was bent at a 90-degree angle and served as grip surface for the operator’s fingers to move the lever. On the inside surface of the lever was a small dimple designed to position the lever in one of two small, shallow circular depressions drilled into the receiver. The depressions were used to retain the lever in the semiautomatic or full-automatic position. On some early guns, the semiautomatic and automatic fire positions were not marked. Provisions for a cleaning rod were located under the barrel. The hardwood stock was secured to the receiver with two wood screws – one placed through each of the steel tangs of the rear receiver trunnion. A flat steel buttplate was positioned at the rear of the stock and secured by two wood screws. A trap door was provided to access a hole drilled into the rear of the stock for storage of a cleaning kit. A sling swivel was located on the bottom of the stock a few inches forward of the buttplate. The loaded weight of the Type 1 rifle with early “slabside” magazine was 10.13-pounds (4.60kg). The overall length was 34.375-inches.

AKS Rifle

To fulfill the requirement of a compact weapon for issue to paratroopers and vehicle crews, a variant was conceived with a folding stock to reduce the overall length for storage or transport. The weapon was designated as the AKS rifle. The letter S for Sklodnoy (a Cyrillic letter C) was added to the designation to indicate that the rifle had a folding stock. The AKS models were fitted with a steel folding stock, which required a special rear trunnion to accommodate its locking mechanism. The trunnion was riveted into place at the rear of the receiver. There were two large 16mm holes provided on each side of the receiver walls to accommodate the pivot pin for the stock to rotate on. The design of the steel underfolding stock was similar to that used on the World War II German MP38 and MP40 submachine guns. The stock’s two strut arms were made from round steel bar stock with lightening cuts milled out of the inside surfaces of each of the arms. The stamped metal skeleton buttplate was attached to the end of the strut arms with two rivets that allowed it to swivel for extending the stock or folding it for storage under the receiver. Early prototype buttplates were an enclosed oval shape, but on production rifles, the buttplate was redesigned with an open top so the stock could be folded with a magazine in the rifle. To release the lock mechanism to fold or extend the stock, there was a checkered push-button on the left side of the pivot pin. With its folding stock extended, the length of the AKS rifle was slightly longer at 34.5-inches than a fixed stock model when measured to the center point of the curved buttplate. The loaded weight was also slightly more than the fixed stock version at 10.26-pounds (4.65kg). Other features were the same as the full stock model.

While the stamped sheet metal AK receiver had proven to be suitably durable during the extensive trials and testing of the weapon prior to adoption, the technology necessary for mass-producing such a receiver proved to be lacking. There have been many conflicting accounts of exactly why the Russians went from the original stamped Type 1 receiver to the milled Type 2. Typically, the Soviets did not divulge a lot of information, especially regarding a design failure. Two of the reported problems experienced early on with Kalashnikov’s Type 1 AK rifle were receiver strength and accuracy. One could surmise that the problem was that the trunnion was not adequately supported in the receiver. Years later, the stamped receiver AKM suffered from similar accuracy problems, which were eventually solved through the addition of the hammer delay system. Other accounts report that it was difficult to hold manufacturing tolerances due to warping of the receiver after riveting and heat-treating.

There have been a number of Type 1 AK and AKS rifles studied by the author, all were fully serviceable, with no signs of any structural failures observed.

During the 1950s, the only viable solution to the Type 1 receiver problem was to switch to a receiver manufactured by the previous, and well-known, method of machining the component from a steel forging. Using this old but proven procedure resulted in slower, more expensive production. While the new milled receiver was being designed, and subsequently manufactured, production of the AK rifles with the stamped steel receivers continued at Izhmash until being phased out around 1951, at which time rifle production was switched completely over to the Type 2 forged/milled receiver. The Soviets have sometimes noted that the Type 2 milled receiver weapon was the “new lightweight model,” but in reality its weight was 6.34 ounces (.18kg) heavier than a Type 1.

(Article excerpted in part from the book AK-47 The Grim Reaper Available from Chipotle Publishing LLC. Telephone: 702-565-0746. www.smallarmsreview.com)

| This article first appeared in Small Arms Review V19N1 (January 2015) |