By Christopher R. Bartocci

Since the introduction of the AR-15/M16 series weapons in the early 1960s, the weapon was envisioned by Colt to be a versatile family of weapons that could serve any purpose required for the mission. Initial designs were for a standard infantry rifle followed by the shorter and more compact carbines. However, there appeared to be a gap in the light machine gun area. Colt’s early experimental models began in the late 1960s with the M16 Rifle HBAR M1 and as of 2009 Colt Defense introduced the Infantry Automatic Rifle (IAR6940).

Early attempts at a longer sustained rate of fire began with the M16 Rifle HBAR M1 (R0606) and the M16A1 Rifle HBAR M1 (R0606A). Both were equipped with a heavy barrel and the only difference between these weapons is the R0606A has a forward bolt assist. Both were selective fire with semi and full automatic settings. Additionally, Colt built the R0606B which utilized the Foster Sturtevant designed (US Patent No. 3,292,492) four-way selector offering semi, fully automatic and a 3-round burst modes of fire. All these weapons fired from the closed bolt position and utilized standard triangular handguards. These models were developed mainly for the SAW trials. Later models of early generation heavy barreled light machine guns included the R0613M16A1 HBAR with an untapered barrel but still utilized the triangular handguards.

During the same time period, there were several experimental belt fed variations of the rifle. These would include the Colt belt-fed M2 HBAR and the CAR-15 Heavy Assault Rifle M2. Small numbers were made, primarily to be evaluated as helicopter door armament (November 1964).

The first dedicated LMG began in the mid 1970s as part of the SAW (Squad Automatic Weapon) program. This was called the XM106 and had two main departures from what Colt had previously worked on. First, this utilized a removable barrel using a lever that was bushed downward and the barrel assembly would slide out the front of the upper receiver. The gas tube was attached to the barrel assembly along with a small triangular handguard assembly to prevent the shooter’s hand from being burned when the barrel was replaced. The upper receiver of the weapon had a vertical pistol grip and a folding bipod. The second, and most significant modification of the weapon, was this one fired from the open bolt position. The hammer was the sear to hold the bolt open until the trigger was pulled.

The First Production Colt Open Bolt Machine Gun

Rob Roy, then in charge of military sales, initiated the development of an additional member of the growing M16 family of weapons to include a light machine gun that would maximize as many parts of the current weapon system as possible. The early stages of development of this new weapon were prior to the design and release of the new M16A2 rifle, but some of the developments of the LMG would surely impact the design of the M16A2.

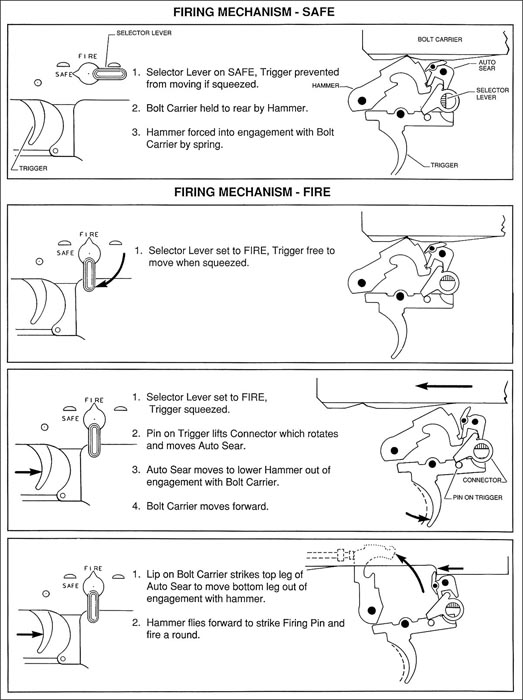

The LMG would fire from the open bolt and fire only fully automatic. There are benefits to the open bolt mechanism; with the biggest advantage being to prevent cook-offs as there is no round sitting in the chamber. This also aids in cooling of the weapon by allowing air to circulate in and out of the bore. The task of developing the open bolt mechanism was given to one of Colt’s finest designers, Henry (Hank) Tatro. On February 28, 1984, Tatro was granted US Patent No. 4,433,610 for his “Open Bolt Mechanism for Automatic Firearm.” This was a truly unique mechanism. The standard M16 lower receiver is used and the only difference is the marking on the fire control: only Safe and Fire positions, no semi option. However, the fire control components could be dropped in any selective fire lower receiver. One of the most fascinating features of his design is the hammer serves two purposes. First, it is the sear which engages the bottom of the bolt carrier to hold the bolt in the open position and the second function is the hammer also strikes the firing pin to fire the cartridge. The Tatro-designed fire control group consists of a hammer, trigger, connector, selector, automatic sear and bolt carrier. The selector only has two positions. The automatic sear serves two functions: pulls downward on the hammer to release the bolt carrier group and also releases the hammer when struck by the bolt carrier to fire the weapon. The connector is the link from the trigger to the automatic sear used to pull the hammer downward to release the bolt carrier.

The Colt LMG Open-Bolt Cycle of Operation

The charging handle is retracted, pulling the bolt carrier group all the way to the rear where the hammer sear will engage the notch on the bottom of the bolt carrier holding the bolt carrier group in the open position. A loaded magazine is inserted into the weapon. With the safety in the Fire position the trigger is pulled. When the trigger is pulled, the pin on the trigger lifts the connector, which in turn rotates the automatic sear, which lowers the hammer out of engagement with the bolt carrier releasing the bolt carrier group forward. With the forward movement of the bolt carrier group the bolt lugs strip a cartridge from the magazine and feed it into the chamber. As the bolt moves into the locked position the sear trip on the bottom rear of the bolt carrier tips the automatic sear releasing the hammer to strike the firing pin.

The firing pin strikes the primer firing the cartridge. As pressure increases the projectile moves down the bore. Once the projectile reaches the gas port located under the front sight assembly, a portion of the gas flows up the port and into the gas tube. The gas then enters the bolt carrier key and then into the expansion chamber located in-between the back of the bolt and bolt carrier. This evenly distributes the gas pressure creating a hammer like blow pushing the bolt carrier group rearward and simultaneously unlocks the bolt. As the bolt carrier group moves rearward, the fired cartridge case is extracted from the chamber and ejected out the ejection port. As the bolt carrier group continues to move rearward, the hammer is pushed down and engages the automatic sear where it is held. When the bolt carrier group reaches full rearward travel, the recoil spring thrusts the bolt carrier group forward stripping another cartridge from the magazine and the cycle repeats. If the trigger is released, the connecter rotates again allowing the hammer to rise and catches the bolt carrier and holds it to the rear. If the magazine runs out of ammunition, the bolt catch will lock the bolt carrier to the rear. When the magazine release button is pressed, the magazine catch pushes outward on the extended arm of the bolt catch releasing the bolt carrier group to the hammer. The weapon is now ready to fire once the magazine has been changed.

Other Modifications Creating the Colt LMG

Colt’s Stanley Silsby and Henry Tatro developed a hydraulic buffer which slowed down the cyclic rate of the M16-family of weapons back in the mid 1970s. The project lay dormant until the development of the LMG. This hydraulic buffer decreased the rate of fire from 700-950 rounds per minute to 600-750 rounds per minute. Not only does the lower cyclic rate increase accuracy but it also conserves ammunition and helps to extend the barrel life.

The description of the function of the hydraulic buffer is best described as written in the patent:

A recoil assembly of the invention includes a buffer having a tubular housing sealed at the rear end by a bumper adapter to engage the end of the receiver extension and by a piston at the front end adapted to engage the a reciprocating bolt and carrier assembly. A spring, seated upon the bumper, urges a sliding seal in a forward direction. The volume between the seal and the piston is filled with hydraulic fluid and contains an orifice, fixedly mounted in the housing for furnishing hydraulic resistance to movement of the piston.

…the buffer travels with the end of the operating spring which is seated against the flange thereof. At the end of the recoil stroke, the momentum of the bolt and carrier assembly causes depression of the piston from its original extended, thereby increasing the time interval of the recoil stroke. During the return stroke, the spring loaded seal within the buffer pushes fluid through the orifice in the opposite direction, thereby to return the piston to its original position. Since the buffer of the invention has its interior volume between the seal and the pistol filled with fluid, hydraulic resistance commences as soon as the piston is displaced.

Part of the job of a light machine gun is to put down heavy and accurate sustained fire. That fire may be at personnel or at area targets. Henry Tatro felt the standard field sights were insufficient for the task so he redesigned the rear sight. The rear sight’s main difference was that it would be fully adjustable for both windage and elevation. Tatro developed a separate rear sight base whereas elevation is adjusted by a dial under the base. He also felt there should be an easier way to adjust the rear sight rather than using a bullet tip. He designed a windage adjustment knob eliminating the need for a projectile or tool to be used to change the windage of the weapon. This design eventually was chosen and utilized on the M16A2 and continues on the detachable carrying handles for M16A4 rifles and M4 carbines today.

As previously stated, Colt developed heavy barrel versions of the M16-family of weapons in the early 1960s; however, not like this. The barrel of the LMG was significantly thicker with an overall diameter on nearly one inch. New handguards were developed that were square in shape and also interchangeable with no separate left and right handguard. Due to increased weight, a FN-FAL style carrying handle was added to the top of the middle of the barrel. An M60 bipod was also added. There was no forward assist due to its open bolt operation.

Left in the Depths of the Colt Model Shop

At the time the LMG was developed, the Colt workforce was entrenched in a lengthy and continuous strike. The LMG remained in a prototype stage and due to other priorities Tatro went to work on the M16A2 development. There were no time, money or product development teams available to complete the project and get it into production.

The LMG’s Second Breath from Canada

During this turbulent time Colt had entered into a licensing agreement with the Canadian government to manufacture M16A2-varients for the Canadian Forces. The manufacturer chosen by the Canadian Forces was Diemaco, a division of Herouex Devtek of Kitchener, Ontario. Diemaco was much smaller than Colt and had a first-class design team. They had ideal conditions at the time to take a product under development and get it ready for production. Phil O’Dell and Ian Anderson went to the Hartford plant to look at the LMG and agreed the Diemaco Product Engineering Department would take on the task. Under license of Colt, Diemaco would devote the engineering resources, fixturing costs and testing costs necessary to move the LMG into production.

Like the Canadian C7 and C8 weapons, Diemaco would use their proprietary hammer forged barrels for the LMG. The diameter of the barrel was changed to accept the newly developed yoke, which the carrying handle and vertical pistol grip would be attached. Diemaco also redesigned the bipod to have adjustable legs. Several design enhancements were added to the LMG from the fruits of M16A2 development including the new finger groove pistol grip, re-enforced lower receiver, the integral fired cartridge case deflector (Brunton Bump) as well as the use of the new canted delta ring to make it easier to remove the handguards. Another very interesting change made by Diemaco was the redesign of the gas tube. Due to the increase in sustained rate of fire, the gas tube had to be modified by increasing both the inside and outside diameter of the gas tube. This helped deal with heat as the larger internal diameter increased the internal volume of gas, which lowered the temperature and operating pressure within the carrier.

The final design was completed and put into production in the winter of 1987 and early 1988. This first model was the M16A2 LMG (R0750). This weapon was made completely in Canada for Diemaco sales and the upper receiver and fire control parts were provided to Colt and Colt utilized Colt marked lower receivers for weapons to be sold by Colt.

An updated version was introduced as the CAR or Colt Automatic Rifle (R0750MC) in 2001. This model eliminated the carrying handle in favor of a flat top upper receiver and a mounting lug for a bayonet was added to the barrel. The TRI-AD I twin rail attachment was added to the front sight assembly that enabled accessories to be mounted as well as two sling attachment points one either side of the rifle. Another yoke was added to the barrel for a mounting lug for the removable bipod.

A vast majority of these weapons were sold by Diemaco (or now Colt Canada). Diemaco called these weapons the LSW (Light Support Weapon) instead of the LMG. The LSW was sold to Denmark and the Royal Dutch Marines. The main difference between the LSW was that it fired from the closed bolt and had forward assist assemblies. The countries who procured these weapons wanted semi as well as automatic fire.

The LMG/LSW is a very versatile weapon. The higher weight plus the hydraulic buffer make this an extremely accurate and reliable weapon though the weapon was never sold in large quantities. Up to now, preference has been the belt fed SAW. However, with the IAR program brought out by the Marine Corps for magazine fed sustained fire weapons, the concept may return by demand. Although the LMG was discontinued from Colt Defense LLC in late 2008, the ball was picked up by Colt’s newly introduced Infantry Automatic Rifle (IAR6940) – but that is another story.

| This article first appeared in Small Arms Review V13N12 (September 2010) |