Text & Photos by Jean-François Legendre

This Part 2 of the study on feeding U.S. World War II .50 Browning machine guns is devoted to the belt packing and belt assembling machines.

Belts Packings

The U.S. report dated January 1946 published by the Office of the Chief of Ordnance entitled The Record of Army Ordnance Research and Development contains the essential official information regarding the development of belt boxes during World War II.

Before the United States entered the war at the end of 1941, .50 caliber ammunitions were packed in metal lined wood crate M1917. Most of the ammunitions were packed in 10-round chipboard cartons, 35 boxes in the M1917 crate. During peacetime, most .50 belts were assembled by using units themselves both for ground, air or naval uses. Belts assembled just prior to use were placed in reusable containers considered as an accessory of the weapons.

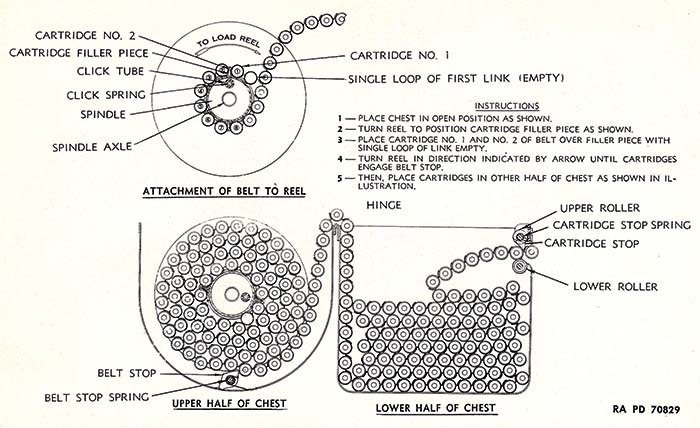

For ground use, three main types of reusable belt chests were in service and considered as a weapon accessory: the aluminum Chest, Ammunition, Caliber .50, M3 with a theoretical capacity of a 120-round linked belt, the steel Chest, Ammunition, Caliber .50, M17 with a capacity of 100 cartridges and finally the large anti-aircraft Chest, Ammunition, Caliber .50, M2 with a capacity of 200 cartridges. For the feeding of .50 Browning machine guns mounted on tanks and armored vehicles, 50-round chests are also encountered.

For naval and airborne services, numerous belt containers were in use specifically designed for each weapon platform and mount.

For ground use, the development of an airtight disposable box for .50 linked belts only began in April 1942 after the development for the .30 cal. airtight disposable box was completed. Accordingly, difficulties encountered with the .30 disposable boxes had been avoided and developments of optimal solutions were considerably accelerated. The Armored Force Board at Fort Knox, Kentucky was charged with the evaluation of the prototypes proposed by three companies: model T12 by Owens-Illinois Can Co., Baltimore, Maryland, model T15 by C.E. Erickson Co., Des Moines, Iowa and the model by Modern Steel Equipment Co., Geneva, Illinois. Finally the model proposed by Modern Steel, incorporating some features of the other two competitors, was adopted as standard on 3 September 1942 as Box, Ammunition, Caliber .50, M2. The lid is secured by a lever system that is locked in place by means of a pin attached to a ring as found in hand grenades. On first models of boxes, this locking ring is permanently attached to the articulated lever in order not to loose it after first opening of the box. On later models, the locking ring is completely removable. The belt box M2 enables to simultaneously fulfill the requirements for storage in depots, for transport and finally for the direct feeding of the weapon during combat. The M2 boxes contain a 105-round linked belt pre-assembled in ammunition factories or more rarely in U.S. Ordnance plants.

Until end 1943, no markings were painted on the outer sides of the M2 boxes. Then all M2 boxes received markings in yellow stencils giving indication on the content. Different marking layouts were used to provide indications on the belting sequence, name and lot number of the organization having assembled the belt and sometimes year of repacking. Although the M2 boxes are in essence disposable, one might note the activities of U.S. Ordnance units deployed in combat theaters and referenced as “Ammunition Renovation Field Units.” These units were dedicated to renovate and repack munitions of all kinds in the field. They were also tasked to salvage, repair and refill with belts the disposable boxes both in .30 and .50 cal. This explains why some M2 boxes are observed bearing several layers of olive green paint over several different markings of successive contents.

At least 14 different WWII M2 box manufacturers are known from specimens: ACME, ARMSTRONG, ARTCRAFT, ASCO, BELMONT, BURROWES, GHW, H, J.B.S.CO, MODERN, NMPC, PALLEY, TBC, UNITED.

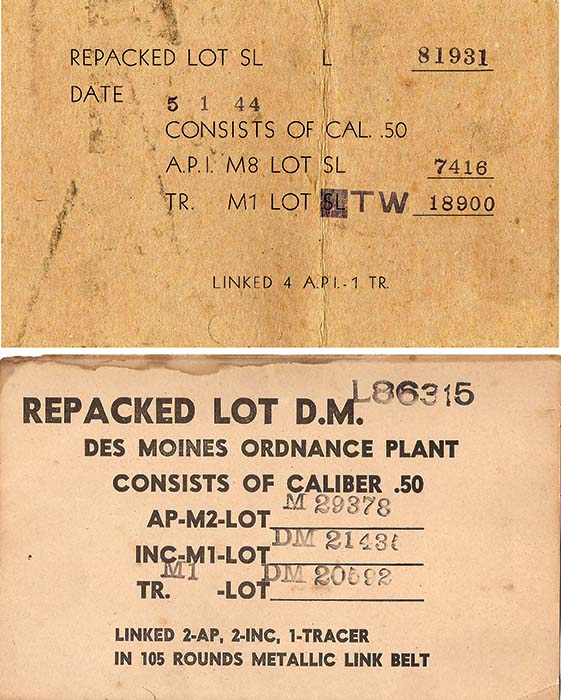

Since pre-filled ammunition belts could contain several types of ammunition, each one bearing its own production lot number, a unique repack lot number was assigned under the designation “Repacked Lot.” This operation of repacking consisted of assembling belts with different ammunition types delivered in 10-round cartons from the ammunition factories. This repacking operation was carried out directly in the ammunition factories or in U.S. Ordnance facilities. The repack lot number is painted on the outside of the wirebound crate containing two M2 disposable boxes and from the end 1943 on, also painted in yellow on the outside of the M2 boxes. A chipboard card named “Repack Reference Data Card” was also inserted inside each M2 box. This card bears indications on the content, the initials of the repacking facility, the repack lot number (with prefix “L” indicating metal link belts or prefix “B” indicating fabric belt), the lot number of each type of cartridges and sometimes the date of repacking. Surviving specimens of those Repack Reference Data Cards remain nowadays seldom seen.

At the beginning of the war, standard belting sequence for ground use was 4 Armor-Piercing (AP) M2 + 1 Tracer (TR) M1. In early 1943, another belting sequence was adopted with 2 Armor-Piercing (AP) M2 + 2 Incendiary (INC) M1 + 1 Tracer (TR) M1. At the end 1943, with the introduction of the Armor Piercing Incendiary (API) M8, the belting sequence became 4 Armor-Piercing Incendiary M8 + 1 Tracer M1. Finally, from mid-1945 until present day, the standard ground use belting sequence is 4 Armor Piercing Incendiary M8 + 1 Armor Piercing Incendiary Tracer M20.

Two metallic M2 boxes were are grouped for storage and transport in a lightweight wirebound crate.

The M7 fabric belts are exclusively intended to be delivered to using units pre-loaded with ammunition and shipped in the disposable M2 box. To the best of the author’s knowledge, the only industrial belting equipment dedicated to the loading of the M7 fabric belts was operated at the Curtis Bay Ordnance Depot, Baltimore.

A rare specimen of an M2 disposable box has been observed bearing the simplified stencils in yellow paint “REPACKED LOT CB-B76942”, the prefix letter “B” before the lot number indicating a fabric belt (the prefix letter “L” denoting metallic Links) and the loading facility is referenced to “CB” for Curtis Bay Ordnance Depot.

Like for pre-packed 105-round linked belts, a specific cardboard “Repack Reference Data Card” for the fabric belt is inserted into each M2 box. This repack data card bears the designation of the repacking facility (so far on “CB” for Curtis Bay Ordnance Depot has been observed), the repack lot number with the prefix B-, the individual lot numbers of each types of ammunition, the belting sequence and finally in full text the indication of the use of fabric belt “110 RD. AMMUNITION WEB BELT.”

Only two standard belting sequences have been identified with the M7 fabric belts: 4 AP M2 + 1 TR M1 and 2 AP M2 + 2 Inc M1 + 1 TR M1. An M2 box and a “Repack Reference Data Card” corresponding to an original loading with M7 fabric belt remain today extremely scarce collector’s items.

For use with airborne Brownings, the ammunition was prominently issued pre-packed on metallic belts. Belts for Air Service were essentially shipped in metal lined M1917 wood chest containing one single 265-round belt. Another standard packing for aircraft belts was an unlined wood chest with a total capacity of 240 rounds containing four 60-round belts packed individually in a chipboard carton wrapped in waterproof paper. From the end 1943 on, the typical chests for aircraft ammunition were painted earth brown and bear in yellow stencils the designation of the content, the type of belting sequence and a symbol indicating disintegrating metallic links.

Although it was always possible in the field to assemble the belts with any specific belting sequences, a few official belting sequences for airborne use were defined. Early in 1942, the standard belting sequence for the U.S. Army Air Corps was 3 Armor Piercing M2 + 2 Incendiaries M1 + 1 Tracer M1. From early 1943 on, the belting sequence was standardized with that for ground use with 2 Armor Piercing M2 + 2 Incendiaries M1 + 1 Tracer M1. At the end of 1943, in an attempt to fight against more heavily armored German planes, the belting sequence was modified to incorporate Armor Piercing Incendiary M8 while still keeping some Incendiary M1, which was better suited against fuel tanks. Belting sequence was then 1 Armor Piercing Incendiary M8 + 1 Incendiary M1 + 1 Armor Piercing Incendiary M8 + 1 Tracer M1. Early in 1944, for the feeding of the numerous Brownings onboard heavy bombers, the proportion of Incendiary M1 was increased with 1 Armor Piercing Incendiary M8 + 1 Incendiary M1 + 1 Armor Piercing Incendiary M8 + 1 Incendiary M1 + 1 Tracer M10. In July 1944, a specific belting sequence was adopted for ground strafing with 4 Armor Piercing Incendiary M8 + 1 tracer M21.

Belt Loading and Linking Machines

The earliest water-cooled M1921 Brownings for ground use produced by Colt were fed with a 100-round fabric belt. The filling of these fabric belts was conducted with a hand cranked machine type B70T of similar design to that for the .30 Browning belts. To date, only a handful of such surviving machines are known in collections.

Air-cooled aircraft .50 Brownings were exclusively fed with metallic links. The earliest linking machines offered by Colt were manufactured by Sargent & Co., New Haven, Connecticut. The design of that .50 linker was inspired from the linker for .30 caliber links used with the Marlin aircraft guns during WWI. The patent for that linker was filed on 23 November 1918 by John H. Shaw on behalf of the Sargent & Co., and patent was finally granted on 22 May 1923 with number 1,456,154. Whereas the original Shaw linker accommodates ten .30 links, the .50 version only accommodates six links. This is the reason why the early M1 links are packed in 6-link chipboard cartons. The linking machine offered for commercial sale by Colt is referenced L-56 and bears, cast in the base plate, the inventor’s reference “SHAW LOADING MACHINE” as well as the manufacturer “SARGENT & Co.”

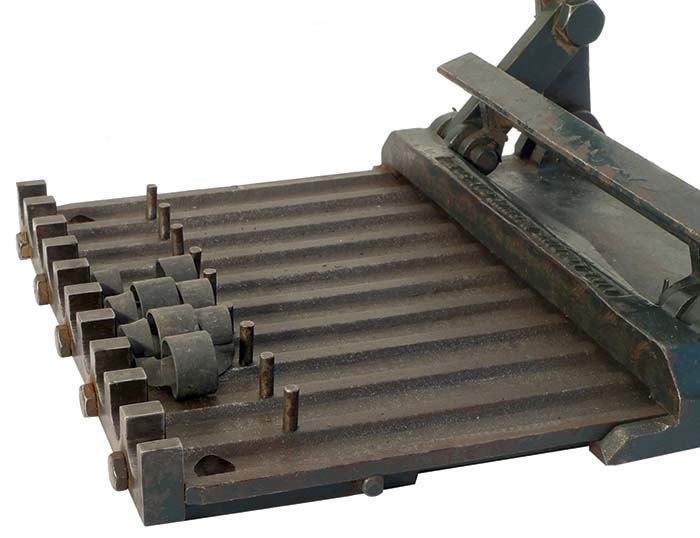

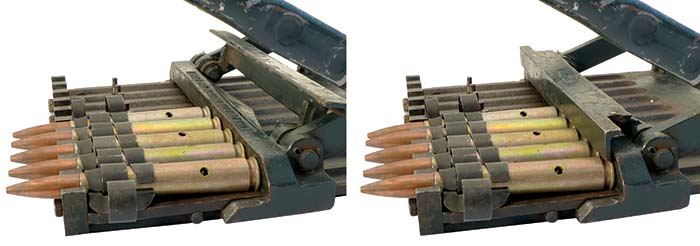

In 1935, a new linking machine was adopted as standard under the designation M2 with U.S. Ordnance drawing number D8794 for the complete machine. The basic operating principle remains the same as that of the Shaw machine with a sliding bar pushing the cartridges into the links. The key difference is the way the sliding bar is put into translation. The M2 linker is designed to accommodate simultaneously 10 links. The sliding bar (made of bronze for earliest productions then replaced by cast iron) bears cast on top the designation of the machine, namely “LINK LOADING MACHINE CAL. .50 M2.” The bottom side of the base plate bears casted the drawing number D8795, corresponding to the base plate only, followed by a revision index.

The U.S. report dated January 1946 published by the Office of the Chief of Ordnance entitled The Record of Army Ordnance Research and Development provides essential background information on the modification of the M2 linker as excerpted in the following.

Reports by Army Air Force units in early 1942 attributed malfunctioning of caliber .50 weapons to corrosion and excess link pull encountered with link-belted ammunition. To overcome this difficulty, field units were required to delink completely belts of ammunition, clean cartridges, and relink ammunition. As there existed no available machine to accomplish the delinking, the Headquarters, Army Air Force suggested an attachment to the Link Loading Machine M2 as the simplest and quickest solution to the problem. Springfield Armory was requested in September 1942 to manufacture a sample delinking attachment for use with the M2 machine similar to that designed by the 4th Air Force. The sample attachment was shipped to the Office, Chief of Ordnance in December 1942. In April 1943, Rock Island Arsenal was requested to manufacture three sets of the delinking attachments of similar design to the Springfield Armory type and assemble them to M2 machines for experimental use. The attachment was designated, “Attachment, Delinking, Caliber .50, T6.” The modified M2 machine consisted first on steel pins inserted into the machine base, the links being then fitted between the pins and the front link stop bar. Second, an extractor bar was hinged to the cartridge insertion bar; the extractor element of the bar was perpendicular to the head of the cartridge and the bar edge fitted into the extractor groove of the cartridge. Extraction was accomplished by pulling rounds by the extractor bar from the belt links which were held by the pins in the machine base.

The Headquarters, Army Ground Forces stated that there was no interest in a delinking attachment for the M2 machines in Ground Forces use. However, as the delinking assembly did not interfere with the operation of the modified M2 machine for linking purposes, there was no objection by the Ground Forces to the modified machine as an article of issue.

An Ordnance Committee Action dated August 1943 recommended that the Link Loading Machine M2 be modified in future production to incorporate the delinking assembly. The modified M2 machine was standardized as “Machine, Linking-Delinking, Caliber .50, M7.” Orders were also issued to modify in the field all M2 machines in Air Force use to incorporate the delinking assembly.

Original M2 linkers modified to the M7 pattern can be readily recognized by the markings cast in sliding bar which originally was “LINK LOADING MACHINE CAL. .50 M2” and where the “2” was grounded off and a “7” stamped in place. These modified machines of course embed the added pins on tray and delinking bar assembly.

After August 1943, all new machines were manufactured according to the M7 pattern and can be readily recognized by the markings cast in the sliding bar which reads “MACHINE LINKING-DELINKING CALIBER 50 M7.”

| This article first appeared in Small Arms Review V18N1 (February 2014) |