interview by Dan Shea

Dear readers of Raffica: On occasion a subject question becomes too large for our normal Q&A format. When that occurs, we move to a “Raffica Special” and we are in that position right now. We have had so many questions regarding the operation of the RPG-7 system that the only way to properly answer this is with a “Special.” Since I have been working on a photo ID series of the various basic RPG systems for many years, and we were just preparing to do the ultimate worldwide ID Guide to these launchers, we decided to prep the readers with this How It Works guide first. Several other articles will soon follow including the RPG ID Guide and an in-depth analysis of the sighting systems. We hope this guide helps dispel many of the myths surrounding the RPG-7 system, and educates our readers to the basic functions and differences. – Dan

Shoulder fired rocket launchers are nothing new. Neither are rifles with integral grenade launchers for that matter. In the 18th century, there were seven foot long flintlock style rifles that a rocket shaft was aligned in, and a transfer bar operated the flintlock mechanism located out at the front of the launcher. The buttstock, trigger group, etc., look normal, then the lock was out at the very front. There was another design from the same period where the buttstock was cylindrical and opened up at the shoulder end to make a cup style grenade launcher. The lock was able to fire either the musket barrel or the grenade launcher with the flick of a switch. The grenade launcher was used mortar style of course. These are mentioned simply to show that weapons designers have been making man portable launchers and hurlers for centuries. It is only in the modern times that we have fine tuned the process.

The roots of the RPG-7 launcher can be found in the German Panzerfaust (literally “Tank-Fist” in German) of World War II. This was little more than a tube with a firing mechanism to launch a primitive warhead, but it gave the infantryman the ability to launch an explosive charge farther than he had been able to previously. Developments during and after World War II went in several directions, with some countries concentrating on the recoilless rifle principle and others looking more to shoulder fired rocket launchers.

In 1948-49, the Soviets introduced the RPG-2 system. The RPG-2 initially was a simple tube with a rocket propelled grenade that was fired from it. Behind the rocket was an expeller charge that basically threw the rocket forward from the tube, and then a pyrotechnic fuze fired the rocket itself when it was safely in front of the operator. The RPG-2 rockets were not reliably timed for firing so the accuracy degraded at distances beyond 100 meters. Stabilization came from six thin sheet metal fins at the rear of the rocket motor, which did a reasonable job for accuracy. The RPG-2 series had an expected range of 150 meters, so the sights were fixed ladder types with no allowance for adjustment. Later models had some modifications, such as a rudimentary blast shield at the rear to help keep any backblast away from the operator. This was neither a blast cone nor a venturi.

The RPG-2 system was manufactured until its replacement, the RPG-7, appeared in 1962. The Communist Chinese built and distributed the B-40, an RPG-2 variant, and the Yugoslav’s built a much heavier similar launcher called the M57.

It is strongly recommended against firing RPG-2, M57, or B-40 rounds as there has not been recent manufacture and the chemical compositions and fuzes are now untrustworthy. Unless the operator can verify recent manufacture, these should be avoided. The launchers themselves are simple mechanical devices so with fresh ammunition they would be fieldable. Antique, outdated and outclassed, but fieldable RPG-2 series grenades do not have timed safety self destruct fuzes, so a “dud” round will become a UXO (Un-Exploded Ordnance) hazard.

RPG-7

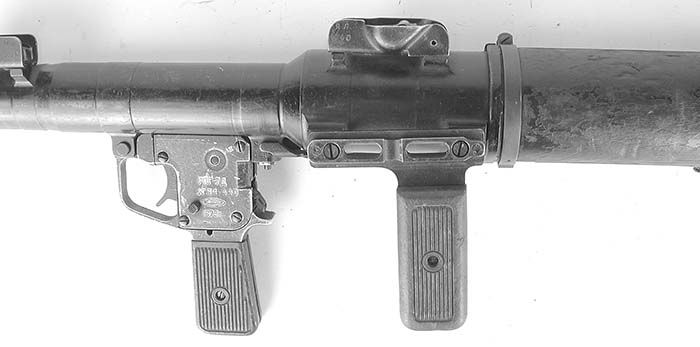

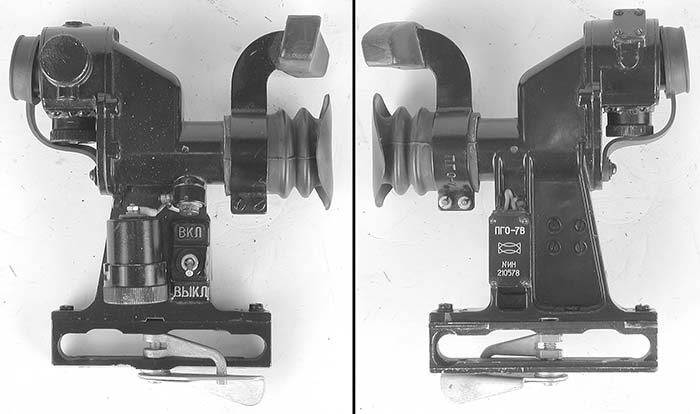

For the purposes of this article, we will be discussing the Russian/Soviet made RPG-7 series: the RPG-7V and RPG-7D. There are approximately 29 different variations made around the world and SAR will be covering models and countries of manufacture at a later date in the ID Guide. Two of the most basic designs have been copied by many countries: the Soviet style and the Chinese style. The fastest way to tell which school the RPG came from is that the Chinese style utilizes a bipod, a shoulder rest, and has adjustable front and rear sights, while the original Russian model does not.

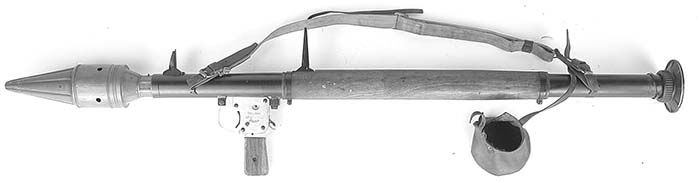

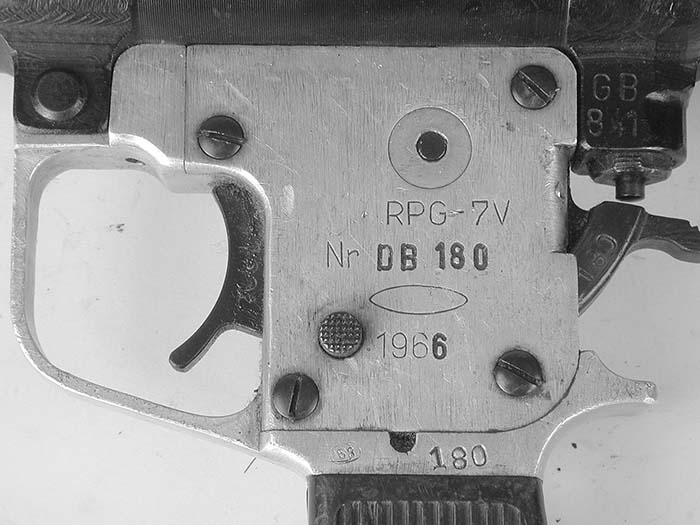

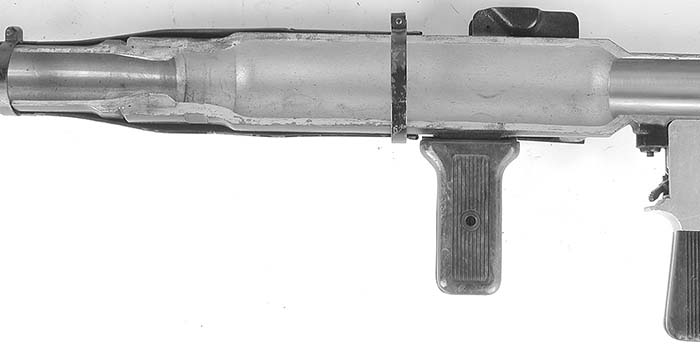

Several initial changes appear in the RPG-7 series. The example in these photos is the second variation, the RPG-7V. The “V” model is simply a bit smaller dimensionally, and lighter. The tube inner diameter remains at 40mm. Several manufacturing method improvements were instituted.

RPG-7D

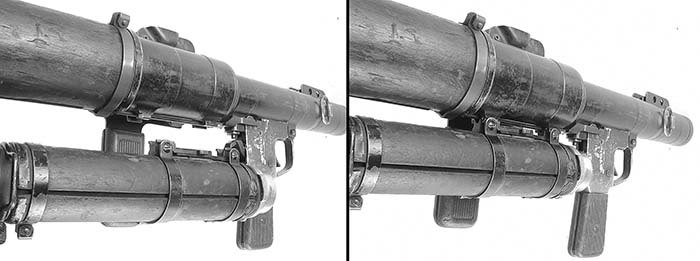

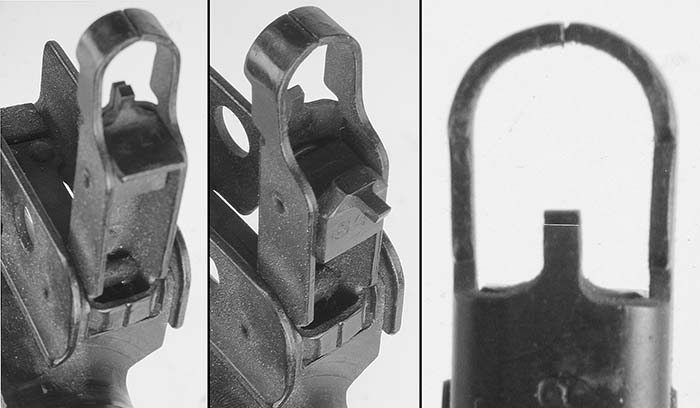

The RPG-7D is the paratrooper’s takedown version of the RPG-7 system, which appeared in the early 1970s. There is a three lug turning takedown point with various safety features built in to avoid firing without the rear of the tube properly attached. There are two bayonet lugs used to attach the rear section to the forward tube, making for a much smaller package for jumping with.

RPG-18

(Side block of four pics)

Aiming and Boresighting

The objective is to hit the target, and more specifically, to strike a crippling blow to the target. If the target is a tank or self-propelled gun, the goal is to take the gun out of action. Simply taking a tread or other immobilizing shot is good but keep in mind that the operators of the vehicle will be looking to return fire, and even if they are immobilized, if they can bring the main gun to bear then the RPG team is in danger as it takes 8-12 seconds to load another round.

Since the objective is to hit the target accurately, there must be a method of ensuring the sights and scope are in line with the bore. In both cases, this is accomplished by using a bore sight and a point of aim that is a minimum of 900 meters away. At the shop it is easy enough to have a set of blocks and a mount in order to immobilize the tube for this procedure, but field expedient tricks include sandbags and either a table or other flat surface. Remember to leave room with the bags for line of sight on checking the sights. This should be done by unit armorers and the operators as well, just like checking any other weapon sight when getting ready to fire. Well trained teams will constantly check their bore sight.

The bore sight is usually composed of two pieces. They are both tubes and the front has a wire crosshair on it and this is inserted into the front of the tube. Some of these front pieces require the operator to put two strings on it to make the crosshairs making it possible to improvise this front section by crossing two strings over the front of the tube at 90 degrees to each other and securing them in place. As long as the crosshairs are centered, this is fine. The rear tube, if used, has either four slots with an open center, or simply an open center, that slides into the blast cone. Visually check from the rear aperture to the crosshairs in the front of the tube, and this will give you a bore center. It is quite possible to bore sight without the rear section, by moving back a bit further from the rear of the tube when sighting.

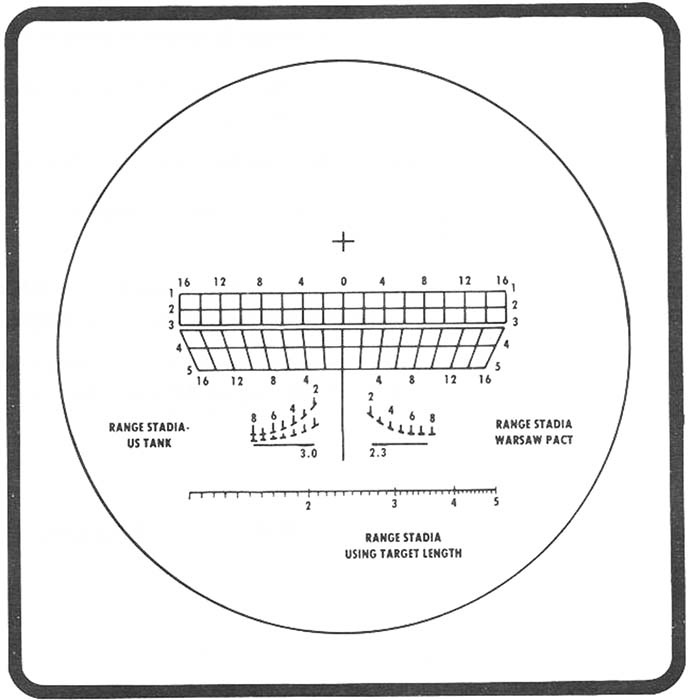

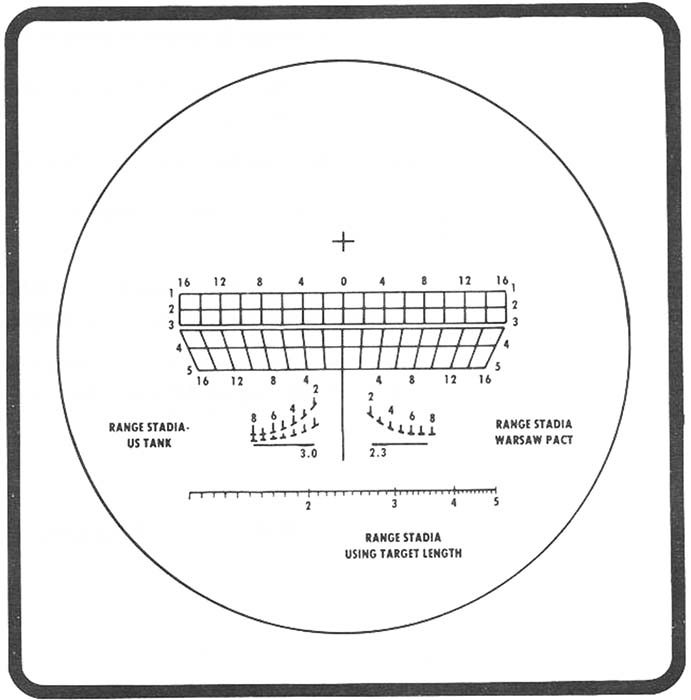

With the tube immobilized, the operator should fix the bore sight onto an object at 900+ meters. The object should have some distinct horizontal and vertical features. Once this is sighted, the mechanical sights can be checked. Russian style sights do not have much adjustment to them, but the Chinese family has full windage and elevation adjustment available. Bring the sights in line with the bore sight and the sights are aligned with the tube at all ranges. The scope itself has a single crosshair up above the sighting chart, distinct and by itself. This crosshair is to match the bore sight at 900 meters. Right and left windage and up or down adjustment are controlled by two dial knobs at the front of the sight. Full adjustment will be described in a later article.

The Controversial Optical Sight

Optical sights are controversial because there are several schools of thought on this unit, and it does in fact take a lot of training and live fire practice to use the RPG-7 let alone the optical sight. SAR will be covering the sighting in depth at a later date. Suffice it to say that using this unit requires extensive training.

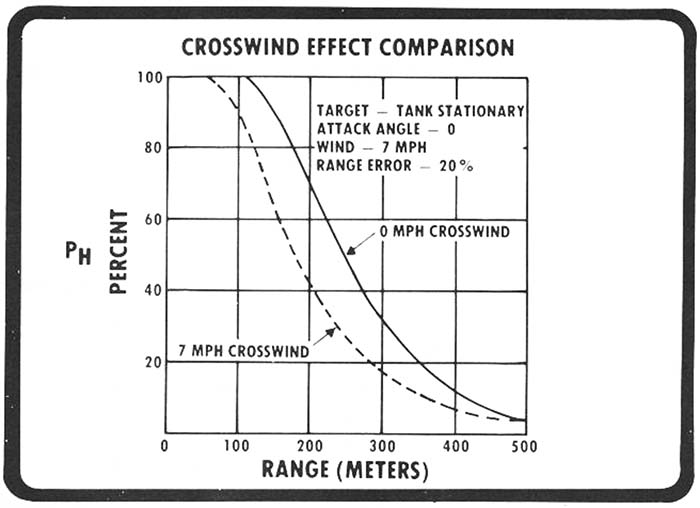

Advice is frequently given that an operator should immediately throw away the optical sight because it is too complicated for combat conditions. This is good advice if the operator is not going to receive a lot of the proper training; novices should stick to the iron sights. However, most RPG-7 operators are dedicated to this job and do receive a lot of training. If that is the case, the optical sight gives many advantages. Combined with a modern laser range finder, the optical sight can truly extend the range of the RPG-7 from its “point-blank” designated 300 meters to a full 500 meters, depending on wind conditions.

Again, experience with live fire is critical to the RPG-7 operator’s accuracy. In the US, it is difficult to get this experience due to our importation laws on explosives and the fact that the US military has a very wise policy of not allowing the firing of captured ammunition of this type. (In the event that there are US end users reading this who need to arrange live fire training outside the US, please see me after class. – Dan)

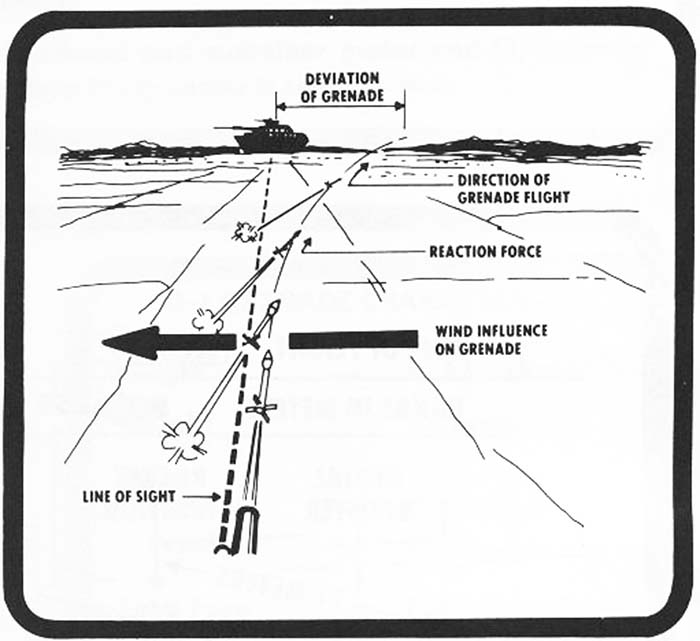

The Wind Thing

RPG-7 Rounds

There are many, many rounds on the market today. SAR will cover these at another time. For our purposes, we are going to take a look at the basic HEAT (High Explosive Anti-Tank) round: the PG7B.

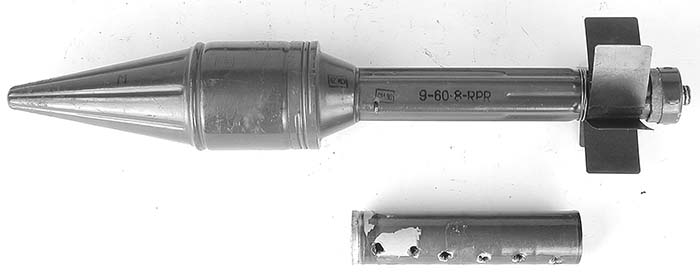

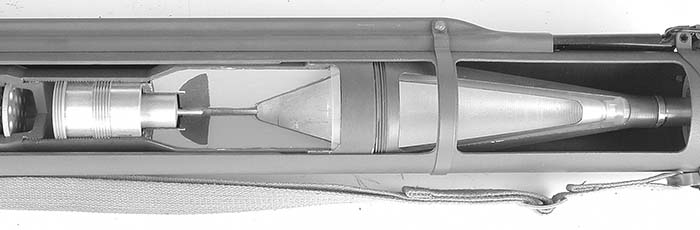

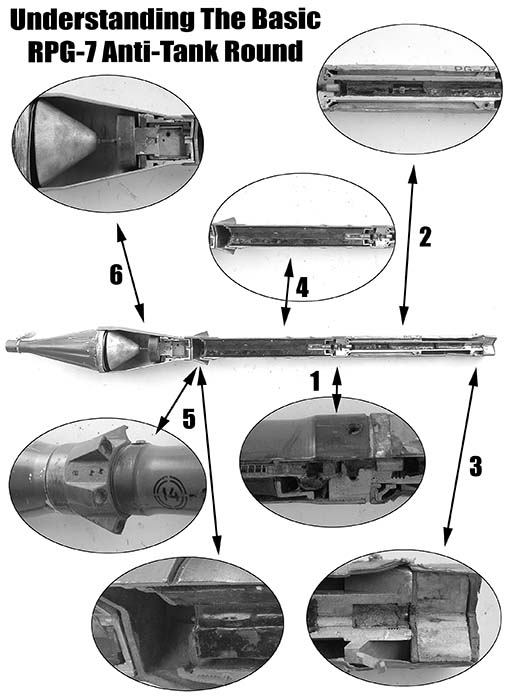

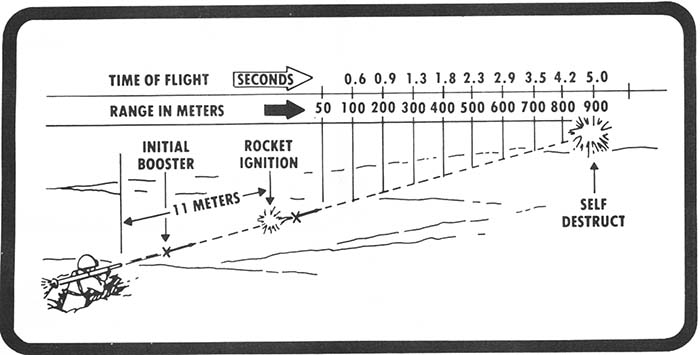

1) At the joint between the expeller charge and the rocket booster that is permanently part of the grenade, is the section that initiates the firing sequence. When the firing pin strikes the primer (located in the small threaded hole on the center side in this photo, but primer is missing) the primer ignites a train of events. Immediately the expeller charge to the left in this photo is ignited. The pyrotechnic pellet in the rocket booster is ignited when enough forward momentum has compressed the spring to the right in this photo, driving a second primer onto a fixed firing pin. This is a timed and blocked event- the rocket motor ignition delay is separated from the primer flash channel by solid aluminum. The pellet burns in a set time to ignite the rocket booster when it reaches 11 meters in front of the launcher.

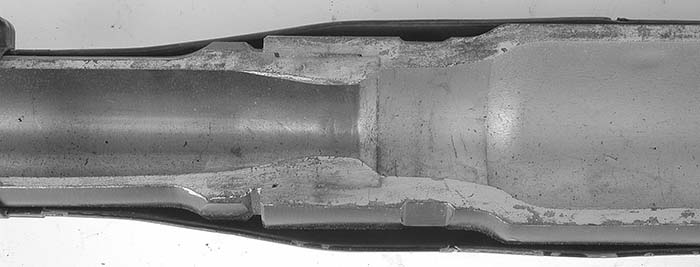

2) When the primer ignites, the expeller charge is fired off by the black powder in the center of the expeller tube. The expeller main charge propellant is double base NC/NG placed evenly around the central tube, in between the folded stabilizer fins. This is all wrapped with impregnated cardboard and a glued, waterproof tissue. This section is extremely vulnerable to moisture, so it is important to only remove from the carrying case just prior to firing. The expeller in an RPG-7 is now in an expansion chamber that is larger than the 40mm tube, so the expanding propellant gases rapidly build pressure and exert it onto the grenade.

3) At the rear of the expeller charge is a hard foam plug. As pressure builds in the expeller chamber, the grenade has forward pressure on it and eventually this plug breaks up and the parts of the plug and any unburnt cardboard are expelled out through the venturi and the blast cone. Directly in front of the plug is an aluminum turbine that imparts rotation immediately as the grenade shaft leaves the expeller chamber and tube.

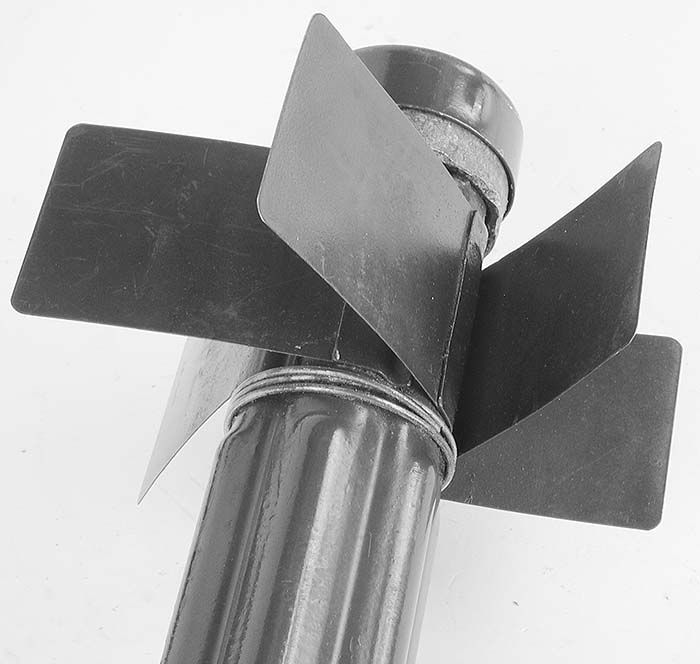

4) As the grenade leaves the RPG tube, it has been “boosted” out by the expeller charge. Forward motion allows the four stabilizer fins to extend out to the sides, and it is important to remember this when firing as there must be at least 8 inches of clearance above all obstacles in the flight trajectory. This is also a good time to point out another reason not to install the expeller cartridge onto the rocket and carry it around. If this is bent or damaged then the entire trajectory may be thrown off. The pyrotechnic pellet will burn through to ignite the rocket booster, as long as the spring held block is out of the way due to proper forward momentum. Propellant gases begin the booster action at 11 meters from leaving the tube of the launcher.

5) The rocket motor burns and the gases push forward into the nozzle block expansion chamber at the front joint just behind the grenade body. This chamber has six holes that point to the rear and outward, and the pressure from the gases blows out the seals and the six holes drive the grenade assembly forward during its assisted flight. It is important to note that the holes are canted in a direction opposite that of the rotation imparted by the fins. The spin rate imparted by the four fins is slowed after rocket ignition. This prevents overspin, and reduces spin degradation of the shaped charge on firing. Just behind the nozzle block is an elastic ring that holds the RPG-7 round in the launcher so slight downward firing is possible without the round coming forward and misaligning the primer and firing pin. When the rocket burns out, forward momentum keeps the grenade airborne until it reaches a target or approximately 900 meters where the safety fuze causes the nose cone area to explode. This does activate the shaped charge, although this author has observed many RPG-7 rounds that reached the five second mark, the safety detonated, and the shaped charge was still intact.

6) Cutaway view of the shaped charge. The piezo-electric nose fuze fires a spark plug system at the rear of the shaped explosive content. As the detonation wave moves through the explosive, the tin coated copper cone at the center is transformed to a high-speed, high-temperature jet of metal that penetrates up to 13 inches of steel armor.

Arming

Firing sequence

Firing the RPG-7 series of weapons is considered a two man operation: the operator and assistant gunner. Both should be proficient with the system and should have a lot of live fire training. The skills needed to hit a target with an RPG can not be gained from simple training drills, especially firing at longer ranges. When the RPG team is “hunting,” it is just as important to figure in attempting to conceal their position and the backblast signature from the enemy as it is to find good front cover. In the case of needing a second shot, the backblast will frequently have located them for the enemy. Aiming so that the rear of the RPG-7 is pointed around the corner of a large building or hill can help with this. A couple of safety points should be emphasized. Behind the tube, for about 30 meters, there is a 70 degree danger zone. Close to the tube is a kill zone. The operator and his A-gunner should always be ensuring that there are no obstacles, walls, etc within 2 meters behind the RPG. Good advice would be to make that at least 3 meters. Blastback can be quite deadly. Firing from inside a small room is to be discouraged. We at SAR have been told that there exists a video clip of an Iraqi insurgent firing an RPG-7 from a third floor window with the backblast hurling him forward out the window. If you have this clip, please forward it to us. It contains sage wisdom for all potential operators.

The operator and A-gunner will have worked together and developed their own method of communicating these sequences, but it is advisable for the A-gunner to be on the left of the operator and reach across to load. This may not always be practical, but it is part of many countries’ training doctrine. Using today’s quality range finders is very important, as accurate range distance should increase first round hit probability. Once the pair have stalked their target, found range and target speed, and set up the firing position, the following sequence of events should occur:

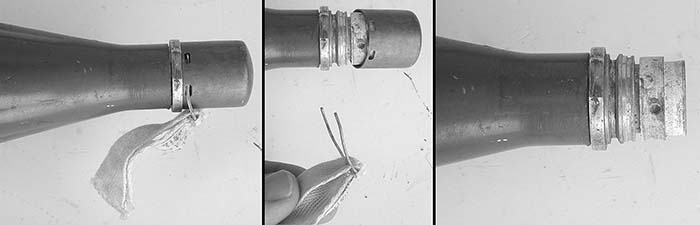

- A-gunner visually clears the tube, then prepares the rounds to be fired, attaching the expeller charges.

- Operator ensures the push through safety is to the right and the hammer is not cocked, then announces “Load”.

- A-gunner loads a round into the tube, ensuring the index is properly occurring and the elastic gasket is snugly in place holding the round in the tube, then visually examines the backblast area for friendlies, to ensure there is no danger to the rear, and to ensure that various and assorted Operator and A-gunner appendages are out of the blast area. He announces “Clear to fire”.

- Operator announces “Ready” and the A-gunner removes the fuze protector and arms the grenade (this may have been done before loading). A-gunner resumes watching backblast area for friendlies and gives warning to the operator if the situation changes.

- Operator cocks the hammer, takes careful aim, pushes the safety to the left, then, squeezing the trigger, he fires. The operator then analyzes shot effect and decides whether to reload and repeat, or to depart the area with all due haste.

- In the event of a misfire, the operator announces “Misfire,” then pushes the safety to the right and “On,” announces “Safe” and the A-gunner makes a fast visual inspection to see if the grenade was properly indexed or not. High probability in a misfire will be that the grenade was not properly seated. If that is the case, the A- gunner then immediately reseats the grenade and initiates checks. Operator fires again. If the grenade was in place, then the A-gunner should pull the grenade forward and visually inspect the primer for a hit. If no hit, try again. If there is a dented primer, then the grenade should be gingerly moved away from the area and left for EOD (on the range) or blown in place at the first opportunity if in the field.

- If there is another misfire, then the A-gunner removes the grenade and inspects the primer. If there is no hit on the primer, then there must be a full check done on the pistol group and firing pin. The A-gunner should re-install the fuze cover and safety pin, then remove the round and unscrew and store the expeller charges and grenades in their carry cases. Under no circumstances should the expeller charges be left attached to the grenades and carried around. The reasons for this should be clear from the discussion of how the rounds work.

Defending against the RPG

A couple of quick notes on defending yourself against RPG-7 attacks. Unfortunately, for most vehicles it is not practical to put up any fencing around the vehicle. Perhaps the best defense is high speed and evasive maneuvering. Don’t drive one constant speed or straight path. The other helpful hint goes to suppressive fire – keep their heads down. If you are hit, remember that a back up shot will probably be coming soon – within 8-12 seconds.

When an RPG-7 is fired towards your position, there are three basic signatures. The first and second are simultaneous: the flash and 30 meter blast area behind the operator’s position, and the flash to the front of the operator (minimal). The third is that approximately 11 meters in front of the operator, there will be a larger puff of smoke where the rocket motor kicks in. This is generally quite visible and a good basis for aiming return fire. If you are in the line of fire, just aim back into the area and suppress. If you are oblique to the line of fire (e.g. the RPG was firing at a vehicle in front of you) aim back 11 meters from the puff and put the hammer down on your guns.

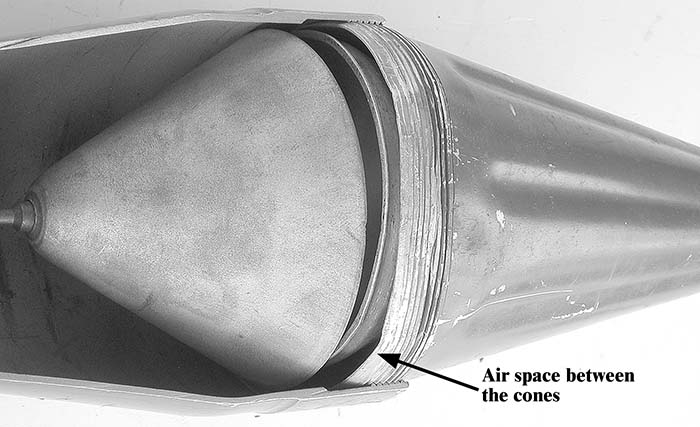

During the Vietnam War, US forces began building portable fencing structures on their vehicles. This was chain link fence or very tight barbed wire. The goal was two fold. First, the fence could catch the round in mid-flight, holding it and keeping it away from the vehicle. If the round then detonates it will not penetrate the armor. Most RPG-7 rounds are designed as shaped charges, so they need to be approximately two inches from the surface of the target when they go off, or they are ineffective. Rounds that have a self-destruct fuze will explode 5 seconds after firing, even if trapped in defensive fencing. This is a danger to soldiers who are unprotected. While the AT rounds are not designed as anti-personnel, there can be enough fragmentation and blast to kill or cause other casualties to those near the explosion. The second reason for the fencing is due to the manner in which the traditional RPG-7 rounds operate. There is a double cone in the front of the stand-off area. The space between the two cones is intended as the path for the peizo electric fuze to ignite the main fuze on the shaped charge. It is quite effective, but if the round strikes the fencing and this cone area is distended and broken, the fuze can’t operate. Newer rounds have a bypass system in place so the best the defender can hope for is to hold the round in fencing, away from the skin of the vehicle, when it explodes. Damage to unprotected personnel can be expected. In the event that the nose fuze strikes a strand of the fence, the round will detonate away from the vehicle, nullifying the shaped charge effect.

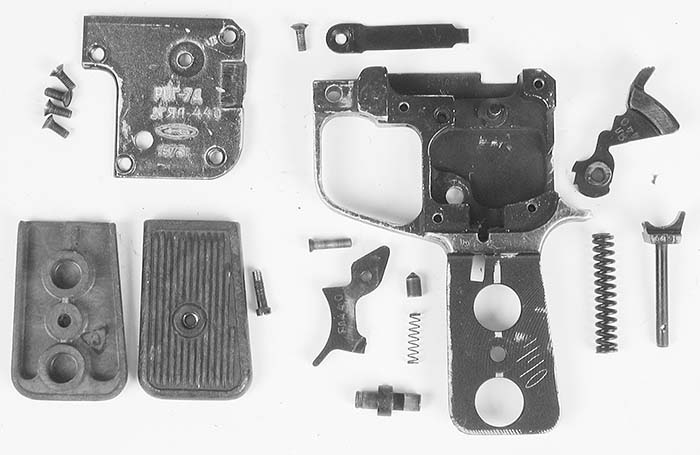

Armorer’s Hints for the RPG-7 Series and the RPG-2

Disassembly of the RPG series at the operator level is confined to removal of the trigger group, the heat shields, scope, and performing inspection and maintenance on these items. There are a number of cleaning tools supplied including a large brush and swab. The interior of the tube is chromium lined but needs frequent cleaning during use due to the corrosive nature of the powder in the expeller charge, as well as how the expeller charge operates. The charge has paper, foam, and burning propellant that is supposedly expelled through the venturi and to the rear, but on occasion particles remain that can either block the next round from being properly inserted, or lead to corrosion. Once the tube is cleaned, a very, very, light coat of oil should be applied internally.

Firing Pin

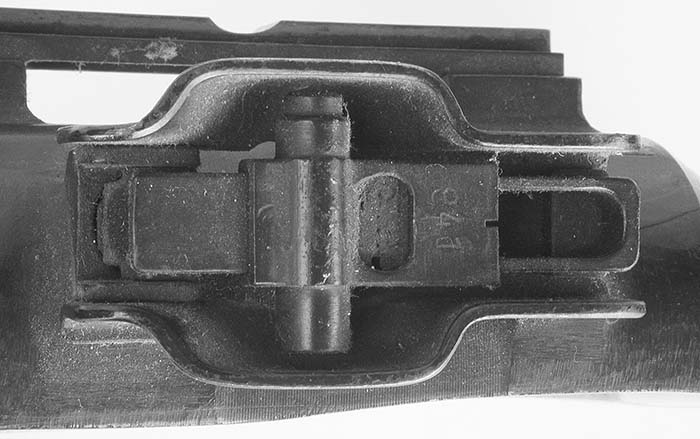

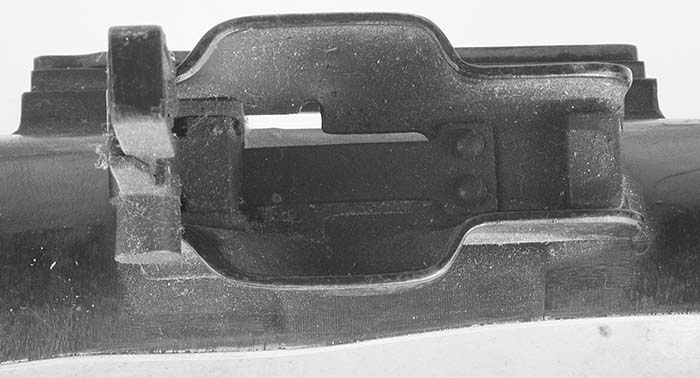

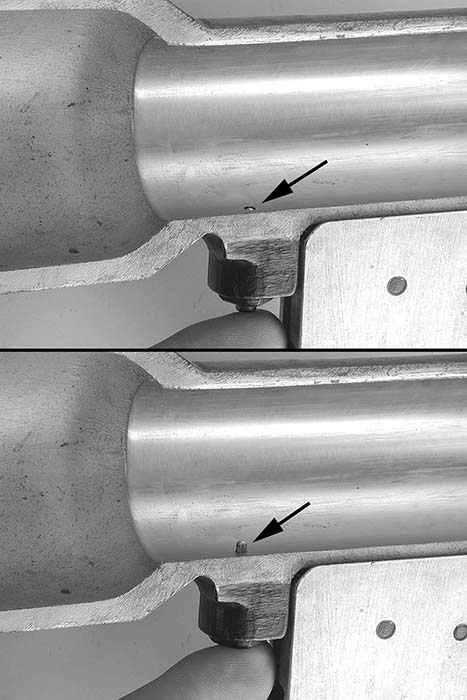

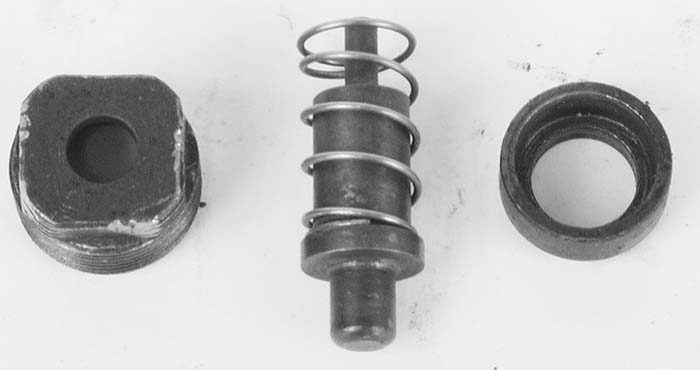

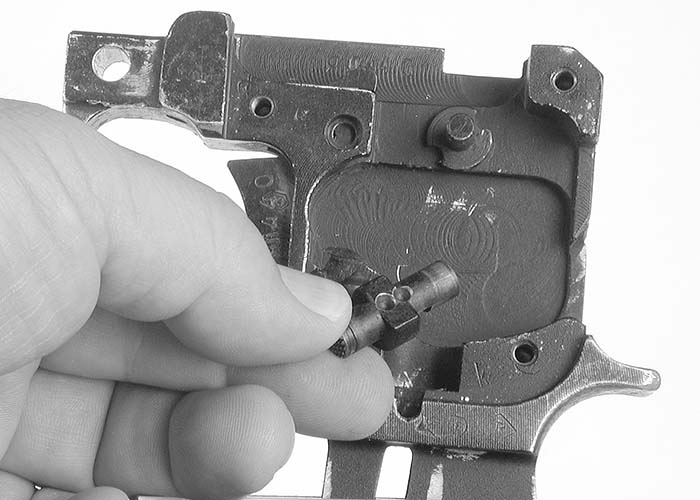

The firing pin location and projection are key to the operation of these systems – and are very basic. There is a double headed pin with a barrel body, which is held in a well in the bottom side of the launcher. One pin is smaller and is the firing pin. The other larger diameter pin is for the hammer to strike. The firing pin hole in the body is aligned with where the primer on the grenade body should be. Any misalignment or change in the extension of the firing pin into the primer will affect the reliability of the firing sequence. The firing pin is held in position by two pieces: a cup that is replaceable and locates the pin in the well, and a threaded plug that holds it into the well. The plug has a hole in it that mirrors the firing pin hole, allowing the striking end of the firing pin to face the hammer. The central body of the firing pin has a spring coiled around it, which keeps the firing pin from entering the firing pin hole unless the hammer has struck it.

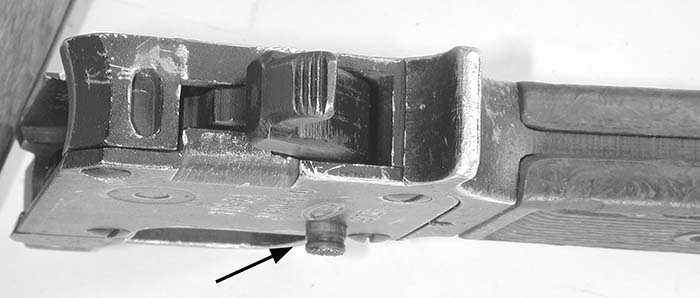

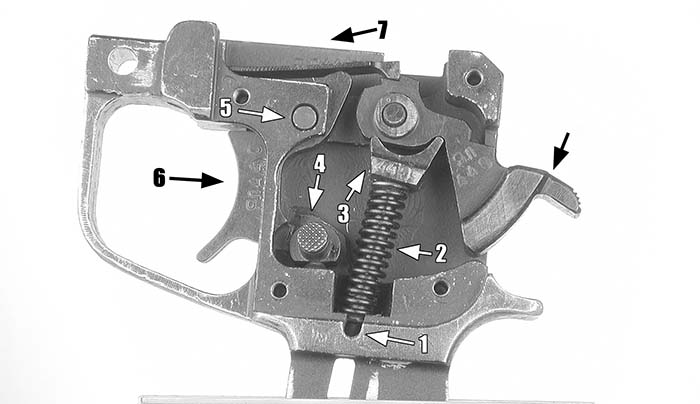

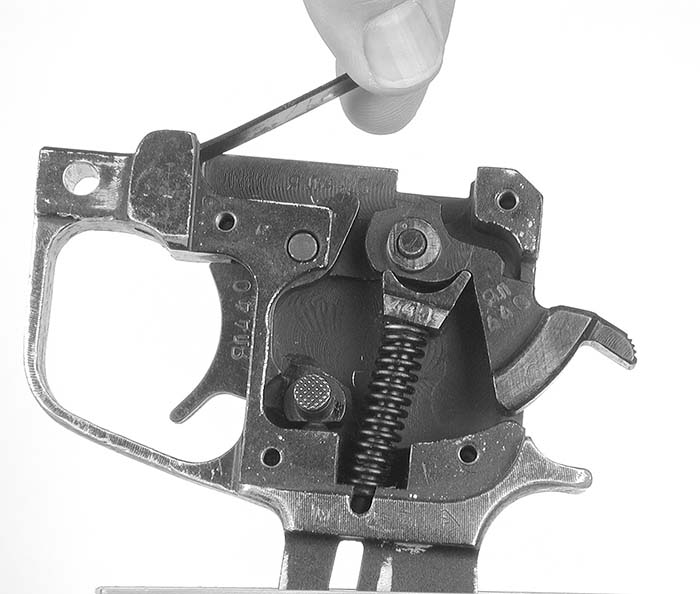

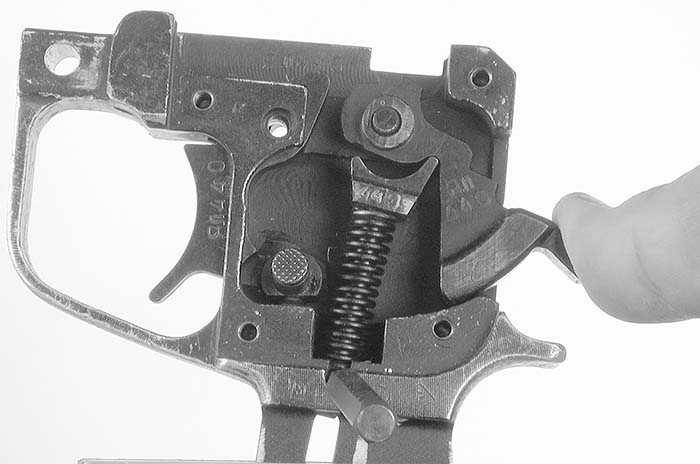

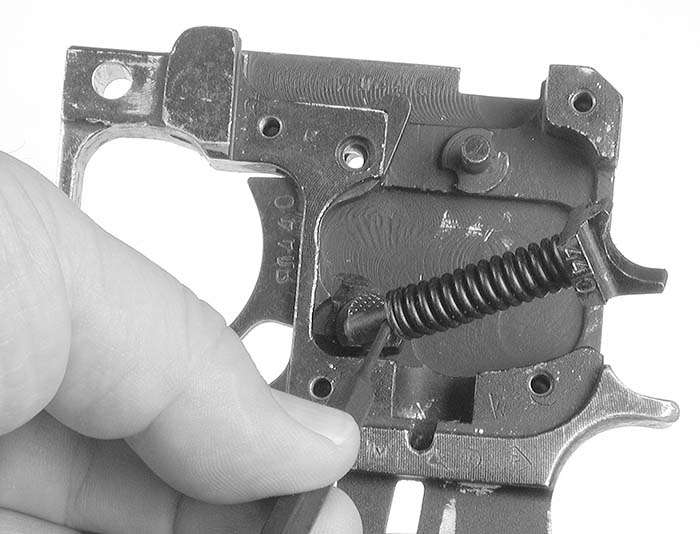

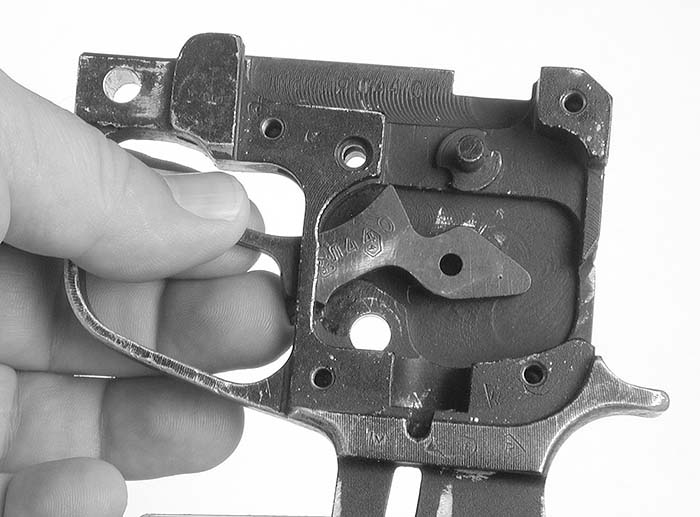

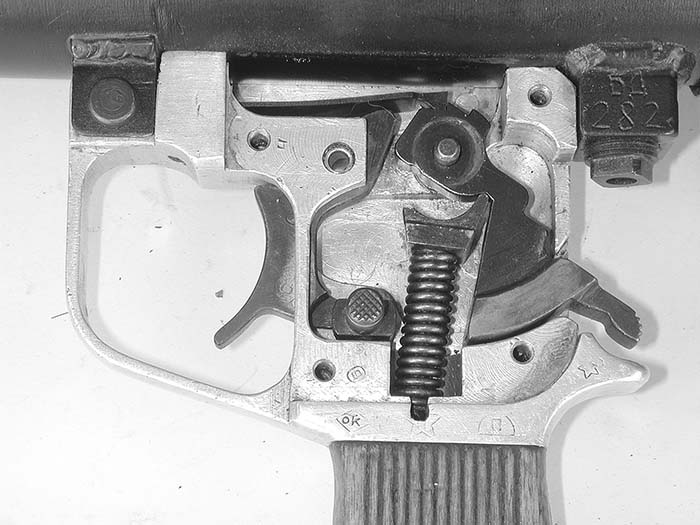

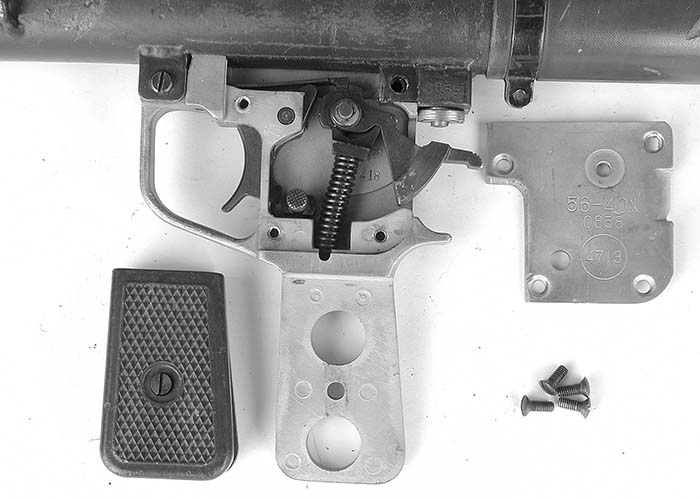

Disassembly of Trigger Group

Most shooters will recognize the internal parts design from numerous single shot hammer fired rifles and shotguns. The design is not unusual. The group is held in position by a fixed lug at the rear and a push through split takedown pin at the front. In the case of the B-40, the front is frequently held in by a screw. There are other variations and removal should be obvious by what method is used. There is a push-through trigger blocking safety, and the hammer is manually cocked. Once cocked, the safety is engaged; left to right from the operator’s view is “Safe” and pushing through from right to left is “Fire.” This can be accomplished using the inside of the index finger, which rests in that area when holding the grip. When the hammer is cocked, the sear engages it and holds it under spring tension from the hammer spring. Once the safety is off, and the trigger pulled, the hammer moves rapidly upward under tension, but it is the momentum of the hammer itself that causes it strike the firing pin. The hammer spring is mechanically kept from forcing the hammer all the way to the top of its cycle. There would be too much force in that case, thus the mechanical block. The cycle repeats.

Disassembly is in the following manner, with one exception. The early RPG-2 and B-40 type trigger groups may have the pin hole for the hammer spring removal in such a manner that the pivot and spring must be removed under pressure. Early armorers had a program to drill out a straight well so that once contained under pressure, the spring could be removed in that contained state and replaced on reassembly.

Send questions to: Raffica sareview@aol.com

Or mail to Small Arms Review Attn Raffica

631 N. Stephanie St #562

Henderson, NV 89014

| This article first appeared in Small Arms Review V10N3 (December 2006) |