By Frank Iannamico

The Thompson submachine gun is certainly one of the most famous and recognizable firearms ever produced. Although the original intent of the weapon was for a military application, the gun had its reputation tarnished by criminals during the prohibition era in the United States. The weapons’ use by gangsters in the 1920-1930s, as limited as it was, made for headline stories in the newspapers of the day. Unfortunately, the million-plus Thompson submachine guns fielded during World War II have often been overshadowed by its comparatively limited criminal use. The gun’s popularity today has been garnered through television programs of the 1950s and 60s by those of us who grew up watching Thompson wielding G-men (and bad guys) on Saturday afternoons.

The Auto-Ordnance Corporation

The Auto-Ordnance Corporation was organized in 1916 by John Thompson to develop a new military service rifle. The early work on the new semiautomatic weapon, dubbed the Auto-Rifle by Thompson, was done in Cleveland, Ohio with a small staff. There was a war on in Europe that the United States would be soon entering. Thompson was understandably anxious to get his weapon developed, manufactured and hopefully adopted by the Army.

When Thompson was setting the groundwork for his rifle project, he was searching for breech mechanisms and other inventions that might be utilized in his Auto-Rifle concept. Before long, Thompson discovered the Blish principle of metallic adhesion. A U.S. Navy officer by the name of John Blish discovered the principle. Blish had theorized that certain metals when set at particular angles became alternately adhesive and repellent under alternating high and low pressure.

As Auto-Ordnance’s chief engineer Theodore Eickoff experimented with prototype Auto-Rifles, he discovered that the Blish principle was simply not workable with any cartridge in the 30-06 class. Upon further development Eickoff discovered that the .45 ACP pistol round was workable with the Blish lock. After Eickoff reported his findings, Thompson then proposed a hand-held .45 caliber machine gun using the Blish lock principle. Soon the work at Auto-Ordnance began to focus on a new weapon, a “sub” machine gun, Thompson pictured as a “trench broom” intended to sweep the enemy from their trenches. Ironically enough, that is exactly what the Germans had in mind when they fielded their MP.18 machine pistol.

The focus of the Auto-Ordnance Corporation shifted from the Auto-Rifle to the development of a .45 caliber automatic weapon. The results of these efforts later to be named the Thompson submachine gun, in honor of the man who had envisioned it, John T. Thompson. After several prototypes and experimental models were built a production model finally evolved. The production gun was the soon to be famous Model of 1921. The initial Thompson production run of 15,000 guns subcontracted out to Colt’s Patent Fire Arms Manufacturing Company, had taken only 16-months to manufacture.

The Men Behind the Thompson Submachine Gun

John T. Thompson

John Taliaferro Thompson was born in Newport, Kentucky on December 31, 1860. He had spent much of his military career assigned to the U.S. Ordnance Department and had worked at the Springfield Armory and the Rock Island Arsenal. Thompson was influential in the United States adopting the .45 ACP cartridge for military use. Thompson accomplished much in modernizing the weapons of the U.S. Army. He left the army in 1914 at the rank of colonel. He then accepted the position of consulting engineer at Remington Arms, during his tenure at Remington, John Thompson gained valuable experience in the manufacturing of small arms.

John Thompson was recalled to active duty in 1917 when the United States entered World War I. Thompson was assigned the position of Director of Arsenals and attained the rank of Brigadier General. He was released from active duty in 1918 after World War I had ended. After his discharge from the Army he devoted his full energy to the Auto-Ordnance Corporation. While John Thompson didn’t actually design the famous submachine gun that bears his name, it would not have existed if it were not for his vision of such a weapon.

Theodore H. Eickoff

After graduating from Purdue University in 1908, Theodore Eickoff accepted a position as a electrical and mechanical draftsman at the United States Ordnance Department. Eickoff had met and worked with John Thompson in the U.S. Ordnance Department’s Small Arms Division, studying the characteristics of foreign military rifles. Shortly after Mr. Eickoff left the Ordnance Department he was recruited by John Thompson to act as the chief engineer of the newly formed Auto Ordnance Corporation. During World War II, Mr. Eickoff served as an Ordnance officer assigned to the Cleveland Ordnance District.

Oscar Payne

Oscar V. Payne was a gifted young man. Prior to working at Auto-Ordnance he was employed by a firm that made patent drawings and researched patents. The firm represented many arms companies. John Thompson, always looking for talented individuals, had learned of Oscar Payne’s unique skills. When Payne left his job at the patent firm, Thompson hired him as Theodore Eickoff’s assistant. Eickoff assigned the job of designing the .45 caliber submachine gun to Payne. Payne is also credited with designing the gun’s box magazine, the “L” and “C” drum magazines. Credit must be given to Payne’s talent as a designer because the final design of the Thompson and its magazines was almost flawless. The designs endured without any major alterations or changes for many years. From 1917 until 1921 he worked at the Cleveland, Ohio engineering facility.

George E. Goll

George E. Goll was a mechanically inclined individual who assisted with the .45 caliber submachine gun project. When the Thompson submachine gun was being marketed, George Goll traveled the globe demonstrating the Thompson to kings, presidents, and army generals. After Eickoff left Auto-Ordnance, Goll took over the position of chief engineer. Goll later became a civilian quality control inspector for the Auto-Ordnance Corporation during military production of the gun at the Savage Arms plant. His initials GEG appear on virtually every Savage Thompson submachine gun manufactured for military service.

Marcellus Thompson

Marcellus Thompson was John Thompson’s only son. Marcellus, like his father and grandfather before him, was a graduate of West Point. Marcellus served as an officer in the U.S. Army from 1906 until 1919 when he left the army in order to work at the Auto-Ordnance Corporation. He would become Vice President and General Manager. Marcellus took over the corporation upon his father’s retirement in 1928. Marcellus died shortly before his father in October of 1939 at 56 years of age.

Colt’s Patent Fire Arms Manufacturing Company

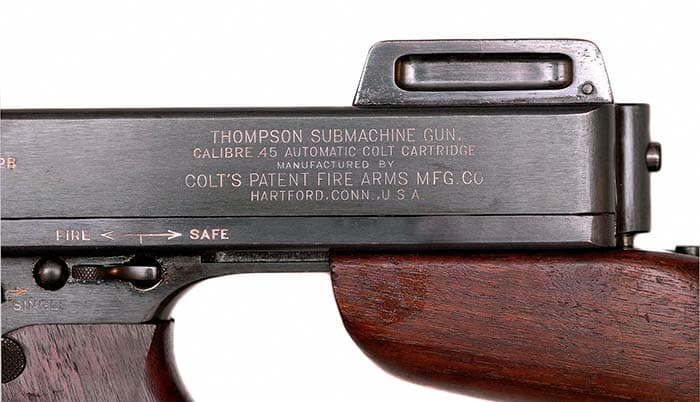

In 1921, an agreement between the Auto-Ordnance Corporation and the Colt’s

Patent Fire Arms Manufacturing Company was reached. The manufacture of the Thompson submachine gun was contracted to Colt who produced the entire lot of 15,000 Model of 1921 Thompsons. The weapon was subcontracted because the Auto-Ordnance Corporation, who developed the weapon, did not have any manufacturing capabilities.

All of the 15,000 Thompson submachine guns originally manufactured by Colt’s were produced as the Model of 1921. From these 15,000 guns, several different models were created and sold by Auto-Ordnance.

The original run of Thompson guns was manufactured to very high-quality standards, common of the era. The 1921 model had a very high commercial quality lustrous Colt blue finish, and complementary fine walnut furniture. The manufacture of the buttstocks and a few other parts were subcontracted out to Remington Arms Company. Originally, the 1921 models were equipped with a vertical foregrip. The Lyman Sight Company of Connecticut manufactured the rear sight assembly for Auto-Ordnance. The rear sight was the ladder type and considered by many to be quite complicated for use on a rapid-fire weapon. The barrel featured radial cooling fins, and a milled ring style front sight. Cutts compensators were not originally fitted to the guns. The actuator, fire mode selector and the safety levers were finely knurled. The one-piece ejector on the Colt guns was machined. Colt manufactured Thompson’s were inspected by Auto-Ordnance’s Chief Inspector John H. Barrett and many have his initials JHB stamped on the right side of the receiver. There is a passionate collector interest in the Colt manufactured Thompsons.

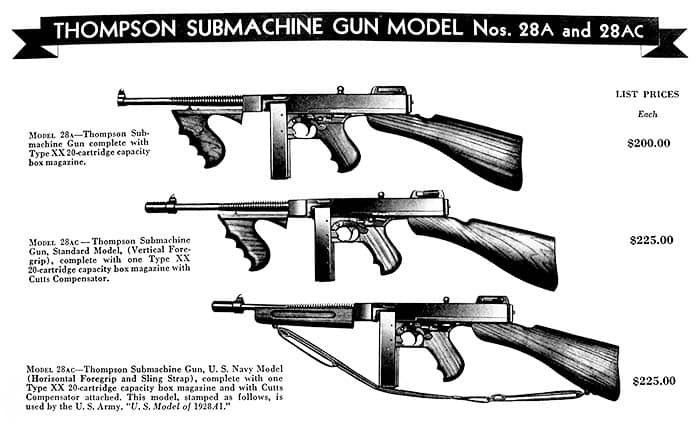

The original cost of the 1921 model was $200.00 supplied with one type XX twenty-round box magazine. The first production Colt Thompson, serial number 41, came of off the assembly line in March of 1921. By this time World War I had ended and there was no demand for new weapons. Sales of the Thompson were extremely slow. It would take almost twenty years to sell all of the initial production of 15,000 guns. The $200.00 list price of the Thompson was quite a sum of money in the 1920’s.

During 1923 a “new” military model was introduced as the Model of 1923. The new model was no doubt influenced by the World War I success of the Browning Automatic Rifle, better known as the BAR. The 1923 military model was nothing more than a standard 1921 model refitted with a longer 14.5-inch barrel, a bipod and a horizontal foregrip. To increase the effective range, a new special cartridge was offered. The new .45 caliber cartridge was called the Remington-Thompson. It featured a 250-grain projectile in a longer .998-inch case. Muzzle velocity was 1,450 feet per second. The concept of the Thompson Military models proved unsuccessful, and few of the 1923 Models were built. The idea was scrapped shortly after it was conceived.

The 1921AC Model

Introduced in 1926, the 1921AC model was simply a standard model 1921 with a Cutts compensator fitted to the muzzle. The compensators for the Thompson were designed by Colonel Richard Cutts, and manufactured by the Lyman Gun Sight Company. The compensator was offered as an enhancement for the 1921 Thompson. The compensator was claimed to significantly reduce muzzle rise and was offered as a $25.00 option. The Thompson Gun without the optional compensator was then designated the 1921A model. There were no changes to the markings on the receivers. The 1921A and 1921AC designations were only used in Auto-Ordnance’s advertising literature. There were several variations of the Cutts compensators manufactured. The early Cutts compensators fitted to existing 1921A Thompsons were not marked, and had a .660-inch inside diameter with 28 threads per inch. A new compensator was introduced in 1932, which was longer and larger in diameter, and had a .750-inch inside diameter with 28 threads per inch. The new compensator was marked with the Cutts diamond trademark and patent dates on the top leading edge of the compensator.

The Model of 1927 Semi-Automatic Carbine

The Model of 1927, semiautomatic carbine is one of the rarest variations of the early Colt Thompson Guns. The 1927 was again, created from existing 1921 models. The unique feature about the 1927 was that it was made into a semi-automatic-only weapon. This was done to offer a model of the Thompson to law enforcement organizations and correctional facilities who simply did not want to arm their officers with a submachine gun. The conversion was accomplished by redesigning a few internal parts. The full-auto markings were neatly milled out of the receiver and remarked. The 1927 model is still regarded as an NFA firearm because of its short barrel and submachine gun receiver. Model 1927 Thompsons are not often encountered in their original semi-auto-only configuration; many were converted back to select fire at some point in time. The 1927 model was available with or without the optional Cutts compensator installed.

The 1928 Navy Model

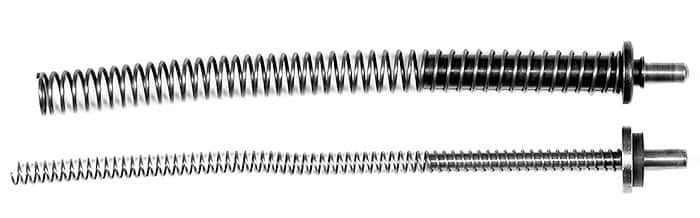

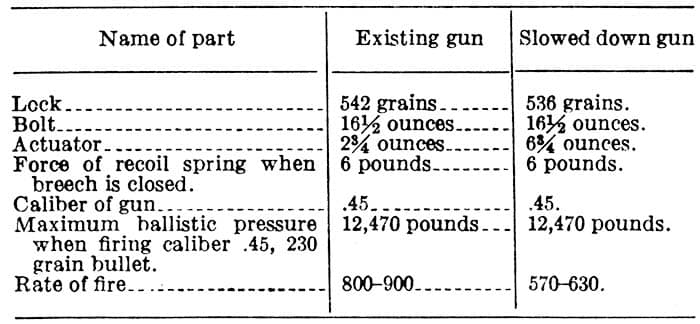

The most prolific Colt manufactured Thompson model was the 1928 Navy model, also referred to by collectors as the Colt overstamp, the 1921 overstamp, 28 Navy or the 28N. The 1928 Navy model, like the others, were created from existing 1921A model Thompsons. It was conceived because of the Marine Corps request to have the rate of automatic fire reduced from 800 rounds per minute to approximately 600 rounds per minute. This was accomplished by redesigning the actuator by adding a block of steel. This made the assembly four ounces heavier, and along with a redesigned recoil spring and buffer pilot, slowed the rate of fire to an acceptable level. The firing pin spring was also redesigned and was slightly shorter than in the 1921 model. All 1928 Navy models had the numeral 1 (in the 1921 designation) overstamped with the numeral 8 to alter it to read 1928. The words “U.S. Navy” were also stamped into the receiver on many of the converted guns. The Navy markings were impressed into the receiver rather lightly and appear different from all the other receiver markings. Although the Colt 1928 “Navy” models were marked “U.S. Navy,” relatively few of the guns actually were sold to the United States Navy. The U.S. Navy endorsement proved to be a very good marketing tool as the “1928 Navy” Thompson was the most popular variation of the early Colt Thompson, and as a result many “U.S. Navy” 1928s were purchased by large corporations, police departments and foreign governments. The 1928 “Navy” Thompson, was available with a vertical or horizontal foregrip, and with or without a Cutts muzzle compensator.

The military often referred to the 1928 Navy Model as the “slowed down model” in correspondence and documents. Although the redesign of the internal parts to slow down the cyclic rate of fire of the Thompson is often credited to former Auto-Ordnance employee Oscar Payne, the new parts were reportedly designed by Philip P. Quayle at the Quantico Marine facility, Quantico, Virginia with U.S. Marine participation. The first “slowed down” Thompson was successfully tested in January of 1927.

In March of 1932, the U.S. Army procured a few of the 1928 Navy Models as “Limited procurement, Gun, Submachine, Caliber .45 U.S. Navy Model of 1928.” The 1928 Thompson would be the last small arm adopted by the U.S. Army that used a year designation in the official nomenclature of the weapon. The Marine Corps expressed interest in the Thompson submachine gun and procured a total of 671 Thompsons from 1926 to 1928. A few of the early Thompsons received by the Marines were in the rapid firing 1921 model configuration. Many were later converted to the slower firing Model of 1928 configuration at a cost of $8.50 per gun.

Unfortunately, by the time the Thompson was finally produced, World War I had ended, and there was no peace time market for the weapon. In addition, the bad publicity the gun was receiving from its use and lagging sales of the Thompson, the future of Auto-Ordnance Corporation appeared quite bleak. By all appearances, the concept of the Thompson submachine gun was a failure. However, as history would soon show, the Thompson gun wasn’t dead yet.

J. Russell Maguire

Russell Maguire was a shrewd businessman believed that with the 1937 Japanese invasion of China and events unfolding in Germany, there soon would be a great worldwide demand for small arms. Through some financial dealings and last-minute ultimatums Maguire was able to obtain controlling interest in the Auto-Ordnance Corporation. During 1939, Maguire subcontracted with Savage Arms to resume manufacture of the Thompson submachine gun, and later opened the Auto-Ordnance factory in Bridgeport Connecticut to keep up with the wartime demand for the weapons.

Despite the design of the Thompson being twenty years old, Russell Maguire would eventually make millions of dollars off of the military contracts for the Thompson submachine gun during World War II. Both John Thompson and his son Marcellus, who had believed so strongly in the Thompson gun, would never live long enough to witness its eventual large-scale adoption by the British and U.S. military.

| This article first appeared in Small Arms Review V25N9 (November 2021) |