A burst of automatic fire from the Colt SCAR Type C. Notice the two fired cartridge cases ejecting from the carbine. This carbine was tested during the SCAR trials and was very used and abused. The ammunition being fired is Black Hills manufactured Mk262 Mod 1 77-grain Open Tip Match bullet.

By Christopher R. Bartocci

Last month we looked at Type’s A and B of Colt’s SCAR (Special operations forces Combat Assault Rifle) program. Both used the traditional gas impingement system as found in the M16/M4 family of weapons and fared very well in the trials. However, there was an unwritten requirement that SOCOM wanted a conventional piston operated weapon. They felt it would be more clean and reliable under the extreme circumstances that they operated under.

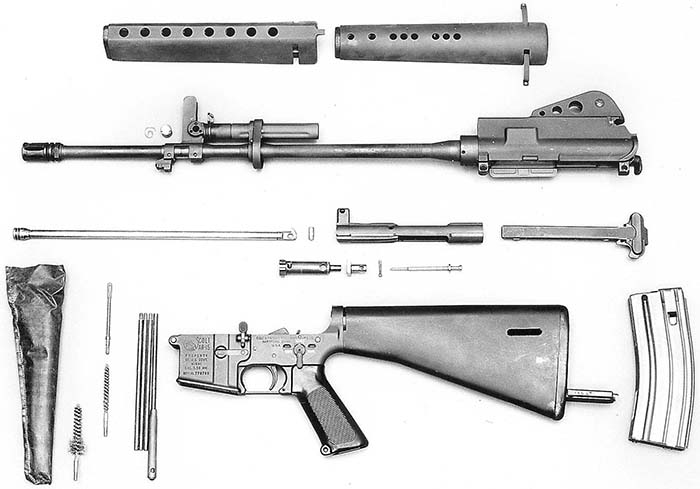

Colt set out to develop their own piston driven mechanism. Piston systems were nothing new to Colt as they had experimented with it many years ago. In the late 1960s to early 1970s, experimentation was going on at Colt, Rock Island and Winchester to develop a standard piston mechanism to deal with the problems the early rifles had with the switch-over to ball powder. This also was as a response to the publicity of the reliability of the AK47. In the end, a report in 1968 stated that the 10 prototype weapons performed about equal to the current M16A1 rifles. Colt developed the model 703 as a piston driven operating system. Although totally unlike the current SCAR design, it indicates that Colt had investigated this in the past. The 703 was a full-length rifle with a piston rod that was attached to the bolt carrier, much like the AK-type piston. By the time Colt had concluded the development of the 703, all the changes made to the M16A1 and ammunition made a piston-operated mechanism unnecessary.

The Colt 703 rifle when fired, the bullet would propel down the barrel, and gas was bled from the barrel into the gas cylinder created between the end of the piston rod and the front sight base. The piston rod, being attached to the bolt carrier group, would move rearward extracting and ejecting the fired cartridge case. When the bolt carrier group reaches it’s furthest rearward motion the buffer/buffer spring would drive the bolt carrier group forward stripping a round from the magazine, chambering it, and the bolt would lock into battery ready for the next shot.

Colt SCAR Type C

SOCOM’s unwritten requirement for a piston operated rifle was based upon their belief that this system kept the gun cleaner due to hot gasses not being blown into the bolt carrier causing fouling. This is especially true when being fired with a suppressor.

Colt began work to design their own piston system. With the requirement for a free-floated barrel, Colt opted to use their newly designed one-piece upper receiver. Keeping the legacy M4 platform was important as it was very user friendly. Once the shooter grasps the pistol grip, all manipulations of the selector and magazine catch can be made without manipulation of the shooters hand. The left hand will insert the loaded magazine a hit the bolt catch to reload. Due to the magazine dropping free and the bolt holding open on the last shot, reloading can be accomplished is seconds. An added benefit to keeping this platform was taking advantage of the existing familiarity of the operators’ use with the M4A1 carbine.

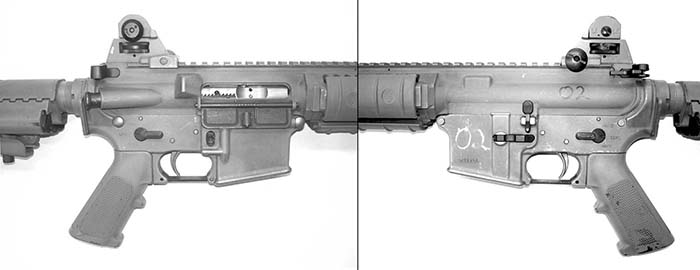

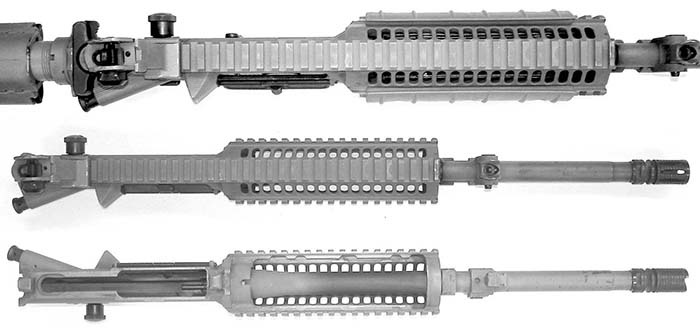

The SCAR Type C Upper Receiver

The upper receiver chosen was the Colt proprietary one-piece upper receiver. This allowed the barrel to be mounted to the receiver and permitted to free float; increasing accuracy as well as assist in cooling. The upper receiver utilizes a forward assist assembly, fired cartridge case deflector and an ejection port dust cover. There is a continuous Mil-Std 1913 rail that goes from the top of the charging handle area to the front sight base. This will allow the mounting of multiple optics including night vision, reflex sight as well as a laser. The side rails allow the operator to mount flashlights or other accessories. The bottom portion of the rail is removable allowing the mounting of a grenade launcher. When the standard cover with the rail is on, a vertical pistol grip may be installed. During testing, the newly designed Grip Pod Systems vertical pistol grip was used. This vertical pistol grip/bipod is made of 7075 T6 aircraft aluminum, the same as the Colt SCAR receivers. The bottom of the grip turns into a spring-loaded bipod with a push of a button. When the operator drops to the prone position and engages the bipod, the carbine has a stable base for aimed firing. When the bipod is engaged and the weapon shouldered, the magazine will not snag on the ground.

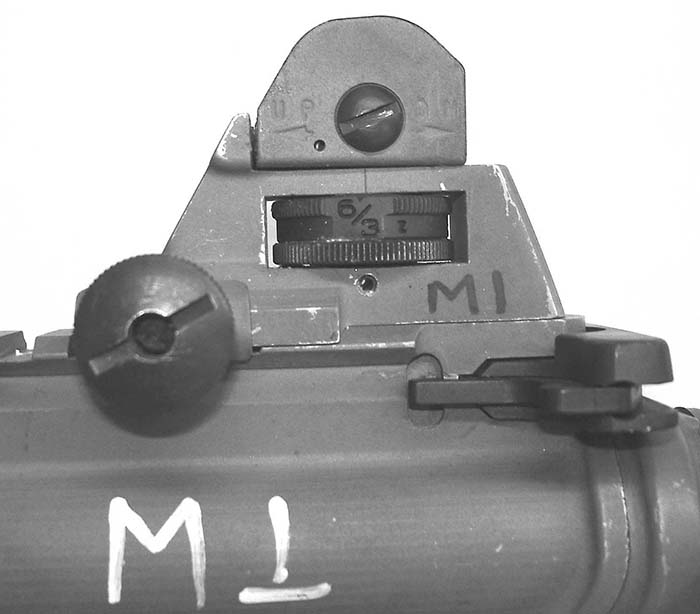

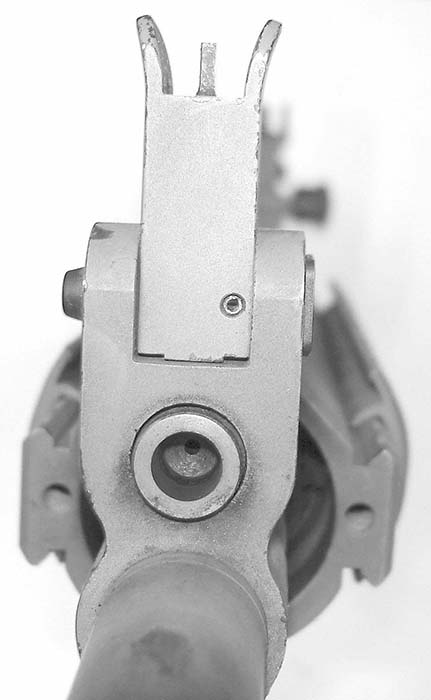

The carbine utilizes the same BUIS (Back Up Iron Sight) as the Colt Type A. The rear sight is a modified Colt carrying handle rear sight. Colt took a standard carrying handle and removed the handle just leaving a lightweight rear sight. There are no sharp edges to snag. It is adjustable for elevation out to 600 meters and has two sight apertures. A 0 to 200-meter close and a long-range aperture. However, any BUIS can be used whether it be an ARMS #40 L or a Knight Armament BUIS.

The front sight is a Colt designed foldable front sight assembly attached to the gas block. This same front sight assembly was used on all three of Colt’s entries and was activated and locked by a button on the left side. This utilized a square 4-notch front sight post and is adjustable for elevation only.

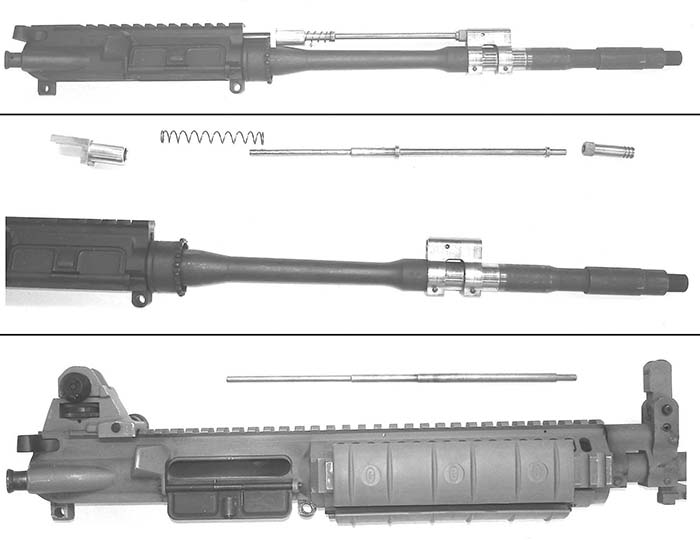

The Colt Piston Operating System

The piston system is very simple and very reliable. In firearms design there are two basic piston systems. The first is where the piston/operating rod is directly attached to the bolt carrier such as the AK47/AKM. The second is the short-stroke tappet where the operating rod strikes the face of the bolt carrier driving the carrier rearward while the piston rod reciprocates back to its rested position in front of the firearm such as the AR18, SKS and FN FAL.

The system chosen by Colt is the latter. By going with the two-piece operating rod the weight may be decreased. Colt has been working on their piston systems for a couple of years in their model shop. In 2003, a prototype was made showing an early attempt of their system. Over the next couple years their design would be modified and perfected to the final system they chose for their SCAR candidate

The final system begins with their proprietary one-piece upper receiver. The barrel is secured to the inside of the receiver and the barrel left free-floating. The system consists of the op rod and return spring. The front of the system consists of the gas cylinder and the mechanism is locked into the weapon by a large pin in the front sight/gas block. There is a gas relief vent in front of the gas cylinder that vents through the front of the front sight assembly. Colt has tested this operating mechanism with over 18,000 rounds without cleaning and without failure. This piston system does not require routine maintenance during cleaning.

As the bullet travels down the barrel upon firing, the bullet passes the gas port and gas is directed into the gas expansion chamber, driving the piston rearward. The rear of the piston impacts a modified carrier key on the bolt carrier group driving the carrier group rearward. While the carrier group continues rearward, the piston rod returns to its forward resting position. On the bolt carrier group’s rearward travel the bolt unlocks, extracting and ejecting the fired cartridge case from the carbine. Then the compressed heavy buffer and spring return the carrier group forward stripping an unfired cartridge from the magazine, feeding it into the chamber, and then the bolt locks into the barrel extension. The carbine is ready for the next shot to be fired. Another benefit of the piston-operated system is the ability to set the cyclic rate of the weapon. Colt chose to make the SCAR Type C fire at 800 rounds per minute comparable to that of the M4A1 with Mk 262 Mod 1 ammunition.

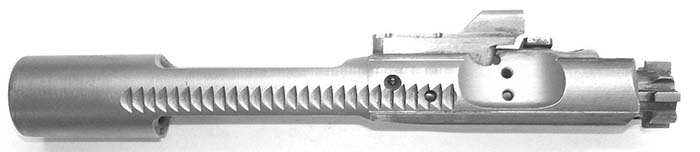

The Bolt Carrier

The bolt carrier group looks very similar to the standard M16/M4 family of firearms but with one major change: a new bolt carrier key. Also, there are no gas rings on the bolt due to the expansion chamber being in the front sight assembly instead of the back of the bolt carrier group. Another innovation that Colt has done is to change the finish of the bolt and carrier. It has a proprietary UCT Defense UltraChem (nickel boron) finish to eliminate the need for any lubricant whatsoever. This slippery finish needs merely a wipe with a rag to clean. This coating also improves corrosion resistance. The extractor utilizes the improved gold extractor spring with the stronger black extractor buffer.

The Barrel

As per specifications, the barrels come in two different lengths. The standard carbine barrel length is 14.5 inches and the CQC (Close Quarter Combat) barrel is 10.5 inches. Both barrels are heavy barrels to insure they can take the required heavy firing schedule demanded by SOCOM. The barrel utilizes the standard 1 turn in 7 inch rifling twist that is required to stabilize the Mk 262 Mod 1 ammunition currently in use by SOCOM. Additionally, as per requirements, a Knight’s Armament Quick Detach flash suppressor is installed for use with the silencer. The front sight base has a bayonet lug for mounting a bayonet on both barrels even though one cannot be mounted on the 10.5 inch barrel.

The chamber has been modified to comply with the “Over the Beach” requirement specified for the SEALS.

The Lower Receiver

The lower receiver is identical to the ones used on Type A and B. It is a standard M4A1 lower receiver with the modified selector lever. As per requirement, this ambidextrous selector operates over 90 degrees of travel (as opposed to the Colt standard of 180 degrees). After testing was completed, this change was not well received. The reasoning in unclear as to whether they were just too used to the standard or if it did not manipulate as fast as the original.

The magazine release is the patented Norgon ambidextrous version. The stock is the VLTOR stock with dual battery compartments for the optics. This is a standard four-position Colt buffer extension with a H2 buffer. Due to the carbine utilizing a heavy barrel, the buffer with 2 tungsten weights and 1 steel weight was necessary to prevent light strikes from bolt carrier bounce. Improved hammer/trigger pins are used that are manufactured of stainless steel. This increases service life especially with heavy volume of fire required of the SCAR weapon. The finish is done in the required flat earth finish (coyote brown) done by Kal-Guard.

Conclusions

The opportunity arose to test fire Colt’s Type C SCAR in their engineering range in the basement of the factory. There was little difference in the feel between the direct gas and the piston driven carbines and their cyclic rate was about the same. The carbine fired was quite worn and neglected from the SCAR trials. However, the carbine functioned flawlessly; firing nearly 500 rounds in 15 minutes. The bolt carrier group was completely dry without lubricant.

There seems to be little doubt that the next generations of M16/M4 carbines will be piston driven mechanisms. Colt plans to introduce a piston driven law enforcement carbine in early 2006.

With the SCAR program moving forward with procurement from FN Mfg. Inc., only time will tell how the new weapons will stack up compared to the M4A1 carbines currently in use. The SCAR trials were without a doubt the most grueling small arms testing in the world since the original Armalite AR-15 was pitted against the government designed M14. Lessons learned in this weapons development program will influence further research and development of further upgrades or new weapons designs of the future.

| This article first appeared in Small Arms Review V10N1 (October 2006) |