By Chuck Madurski

The Avenger. Seldom is a nickname given to an inanimate object as fitting as this. The General Electric (now General Dynamics Land Systems) GAU-8/A “Avenger” 30mm cannon is the largest Gatling gun in the world. It is also arguably the most awesome gun ever designed for and mounted on an aircraft. To be more precise, the Fairchild A-10 “Warthog” was designed almost literally around this gun. The GAU-8/A has also spun-off (no pun intended) a lighter duty version; the four-barreled GAU-13/A. The 30mm ammunition has been the source of many innovations and the whole system has been adapted for the vital job of missile defense for Naval vessels. In this guise it is called Goalkeeper.

The modern interpretation of a big tank-killing gun in a stable flying platform is at least in part based upon the success of the World War II German Junkers Ju-87G, especially as flown by Hans-Ulrich Rudel. Using the G model Stuka with a 37mm anti-tank gun mounted under each wing, with each gun fed by six round clips, Rudel is credited with destroying five hundred nineteen Russian armored vehicles. The actual total is probably much higher. This in about two years time as well.

In light of information like this from several studies, in November 1970 the Air Force issued a Request For Proposal (RFP) for a 30mm rapid-fire cannon for use in the next generation CAS aircraft called the A-X. As a result of their over twenty years experience in designing and building Gatling guns, GE was selected to build prototypes. The contract also covered the development of the ammunition family to be used with the new gun. GE had already been working with a technology demonstrator six-barreled 30mm gun for over two years by then, though it was not until 1974 that a pre- or early-production model was flight-tested. The first production guns came off the line in August 1975, and when production ended in November 1983, 700 had been produced. However, limited production continues for spare parts and guns.

The Gun

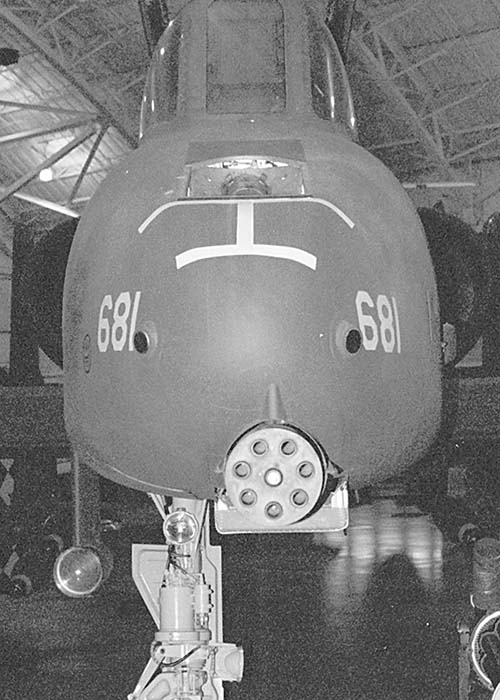

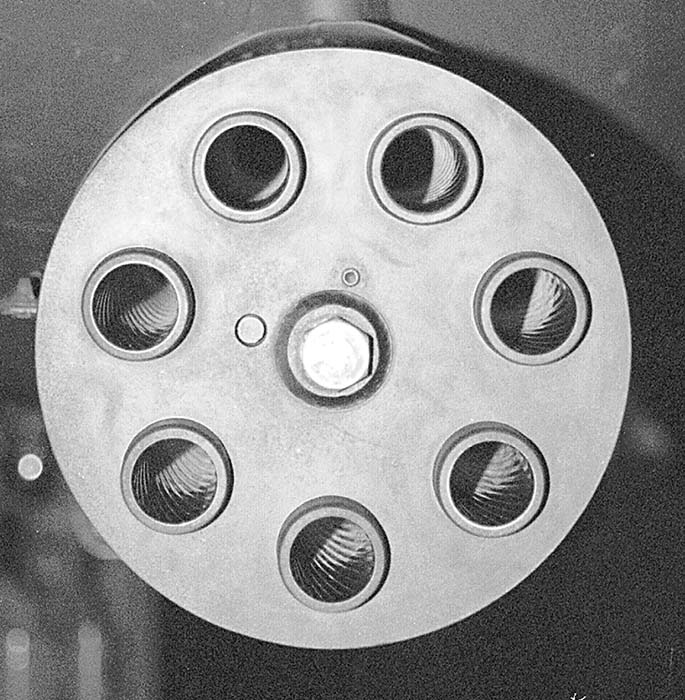

The GAU-8/A has seven barrels. Like all externally powered Gatling guns, its rate of fire is adjustable. However, it generally fires at 4,200 rounds per minute. That works out to only 600 rounds per minute per barrel. At that rate, the barrels have a USAF specified minimum life of 21,000 rounds. The barrels are 86 inches long (not including chamber) and weigh 52 pounds each. They are held to the gun by a quick release mechanism for ease of maintenance. The barrels have right-hand twist rifling with 20 grooves. While the 20mm Vulcan uses gain-twist rifling, the twist rate on the Avenger is constant. Total length of the gun, sans feed mechanism, is 112.83 inches and weighs 661 pounds. The overall length including the linkless feed system is 21 feet. The unloaded weight exceeds 1,800 pounds, while fully loaded weight is nearly 3,500 pounds.

The impressive size and mass pales in comparison to the recoil forces generated by the Avenger. According to the US Navy’s Gun Systems Engineering Center, the GAU-8/A firing at 4,200 rpm has a trunnion reaction (force) of 19,000 pounds! That is 1,000 pounds greater than the combined thrust of the A-10’s two engines a full power. Obviously, bursts are kept relatively short as firing the Avenger is much like slamming on the brakes. This large force also necessitated that the gun be installed on the aircraft’s centerline to avoid having the plane turn off target from recoil forces.

Simply scaling the M61 Vulcan up to 30mm size would have resulted in a much larger and heavier weapon. A clever engineering change to the Avenger’s bolting method led to large dividends in weight savings and in reducing the overall length of the gun. Where the Vulcan bolt locks into the rotor acting as the receiver, the Avenger bolt is a multi-lugged Stoner-type and locks into the barrel extension, similar to the AR-15. Other improvements allowed the gun package to be only slightly larger in diameter than the Vulcan.

Feeding the Avenger

The linkless feed system of the GAU-8/A is based on that of the 20mm Vulcan. Being linkless saves weight and reduces the number of bits and pieces the whole system has to deal with. The cartridges are held in a drum with the projectiles pointed toward the center. A full load consists of 1,100 rounds. This is enough ammunition for about a dozen gun passes before the need to reload. Spent cases are retained in the system and are shuttled back into the drum for unloading when the plane is back at the base. Thus, potential airframe or engine damage from an ejected fired casing is avoided. Unloading the empties and reloading the whole system can be accomplished in about 13 minutes using a ground support piece called the Ammunition Loading System (ALS) that is much like the Avenger’s feed system, although it is trailer mounted.

The drum feed and the gun are powered by a pair of hydraulic motors working together and producing a total of 77 horsepower. That amount of power is required to spool up the seven rotating barrels almost instantaneously and begin the feeding of the ammunition. If one of the motors should fail, the gun is still able to operate but with the rate halved to 2,100 rpm. At the end of every burst, the motors reverse momentarily to decelerate the gun while the feed mechanism clears any live rounds from the barrels to prevent cook-offs.

The Ammo

The 30x173mm ammunition used in the GAU-8/A is available in three common varieties for CAS use, with a few more that are used for anti-missile installations. Unlike the 20mm Vulcan rounds that are electrically primed, the 30x173mm is percussion primed. The main tank killing round, the one that gets nearly all of the (negative) press, is the PGU-14 API(T). This is the depleted uranium (DU) kinetic penetrator round that was so effective at defeating Saddam’s tanks. The DU penetrator is sheathed in an aluminum shell that shatters upon impact, while the penetrator has a high pyrophoric effect. The extreme penetration is due to the high density of the DU, and its relative hardness. Development of the DU shell began in 1972 and was finalized in 1976. The loaded round has an overall length of 11.42 inches, weighs 1.53 pounds and has a muzzle velocity of 3,323 fps. The projectile weighs 0.6 pounds (9.6 ounces). The normal combat load is a 5:1 ratio of PGU-14 API rounds and PGU-13 HEI. The two rounds are ballistically matched, as is the inert PGU-15 TP (target practice) round.

One of the first innovations of 30x173mm ammunition is the light alloy cartridge case which is 60% lighter than the same case would be in steel (5 ounces versus 12.3 ounces). Recall that the normal combat load is 1,100 rounds of ammunition. The weight savings allowed an increase in the ammo load of over 300 rounds or 25% of the total load. Steel case ammunition is used in the Mauser MK30 cannon.

Another important advance pioneered by the 30x173mm round is the successful development of plastic driving bands. Not only do these save some weight, but more importantly, they contribute to long barrel life by reducing wear to one-third that caused by metal driving bands. Furthermore, plastic bands do not tend to foul the barrel as traditional copper bands do. A 40mm version of this round had been developed by simply necking up the case for potential use in Boeing’s Bushmaster II chain gun.

Variations

So successful has been the 30x173mm family of ammunition that several guns have been developed to use this chambering, though they generally use unique projectiles more suitable to their methods of employment. Among these is the Oerlikon KCA that was selected as a back-up in case the Avenger failed. There is also the previously mentioned Mauser MK 30 (Mauser Model F), and Bushmaster II 30mm Chain Gun. Also there was an experimental Rocket Assisted Projectile (RAP) version tested in the 1970’s. To save space, the propellant was wrapped around the penetrator. This round demonstrated penetration at approximately 1,800 yards equivalent to the standard API at 1,200.

An alternate usage for the Avenger is the Dutch Goalkeeper Close-In Weapon System (CIWS). Introduced in the mid 1980’s, it is similar to the US Navy’s Phalanx anti-ship missile system. It is in use by the navies of Great Britain, the Netherlands and the United Arab Emirates. In this guise, a special FMPDS (frangible missile-piercing discarding-sabot) projectile is used. Designed by NWM De Kruithoorn, this round uses a tungsten alloy penetrator in a sabot that falls away once the round has left the gun muzzle. The tungsten alloy used is somewhat brittle and is designed to fragment after penetrating the thin sheet metal that usually makes up the front end of anti-ship missiles, thereby destroying the missile.

Gun Pod

The Avenger had a little brother. A four-barreled version designated the GAU-13/A that was designed to be used in the General Electric GPU-5/A Pave Claw pod. Besides the barrel count difference there are a few other attributes that differentiate the GAU-13/A from the GAU-8/A. The helical feed drum only holds 353 rounds and houses the ammunition with the rounds pointed forward instead of towards the drum centerline. This is done to reduce the frontal area of the pod to a minimum. The pod weighs nearly 2,000 pounds loaded and the gun is powered pneumatically fed by a storage bottle. The rate of fire is 2,400 rpm.

During Desert Storm some F-16s from the 174th TFW were deployed to the Gulf, but the fighter/pod combination did not perform close to expectations. Among the reasons were a lack of rigidity in the pod’s mounting when compared to the GAU-8/A in the A-10 and the severe vibration and subsequent handling problems for the F-16s when the gun was fired. Interestingly, in the late 1980’s the Royal Thai Air Force (Kongtap Agard Thai) fitted Pave Claw gun pods to the centerline pylons of some of their Northrop F-5E Tiger II fighters.

The Warthog in The Storm

Debriefed Iraqi soldiers stated that the single most feared aircraft was the A-10. Firing Maverick missiles, making cannon runs and generally loitering for extended periods looking for more targets generated no small amount of concern for any enemy personnel in the area. The GAU-8/A was utilized from ground level to altitudes of 10,000 feet and sometimes more, by day and at night. To the pilots shooting the guns, they didn’t know until later the effect the 30mm gun was having for when they shot up a tank it was perforated like Swiss cheese, and it tended to burn inside with no secondary explosions. Until Iraqi tanks could be examined on the ground, these kills were listed as only “possible damage”. The Avenger cannon also proved to be an ideal anti-material gun for those times when a tank just could not be found, some of the other favorite targets being SCUD launchers with or without missiles, and artillery sites.

Whether in its element as a tank killing cannon in the snarling nose of the A-10 Thunderbolt II (Warthog) or working as a last line of defense CIWS anti-ship missile gun, the General Electric/General Dynamics GAU-8/A Avenger Gatling Gun has assured its place in history as one of the most important members of the modern Gatling Gun family.

| This article first appeared in Small Arms Review V6N5 (February 2003) |